When it comes to carbon monoxide (CO), the right tool can mean the difference between safety and oversight—or between regulatory compliance and costly downtime. But what’s the actual difference between a CO detector and a CO gas analyzer?

In short:

- A CO detector is a safety device. It sounds an alarm when CO levels rise to dangerous limits.

- A CO gas analyzer is a precision instrument. It measures CO concentration continuously and accurately, often in parts per million or even parts per billion.

If you’re monitoring for safety, a detector may be enough. But if you’re managing a furnace, boiler, or stack emission? You’ll need a gas analyzer—without question.

How Do Carbon Monoxide Detectors Work—and Why Aren’t They Enough?

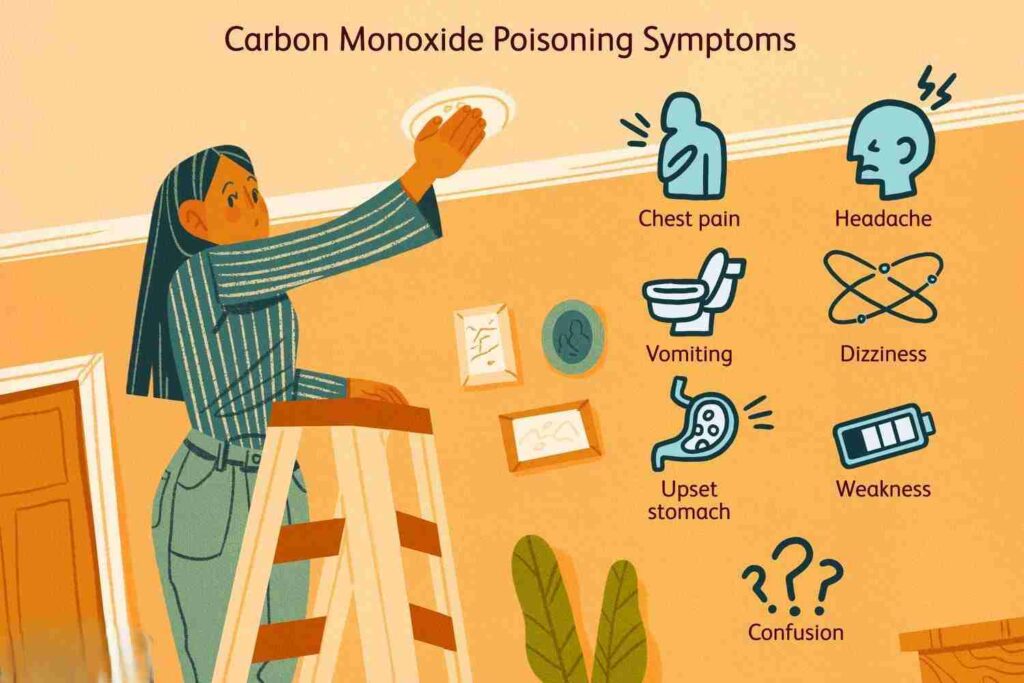

Carbon monoxide (CO) detectors are essential safety devices in homes and offices. They alert occupants to dangerous CO levels, providing a critical first line of defense against this invisible threat.

How They Work:

Most CO detectors use electrochemical sensors. These sensors contain electrodes immersed in an electrolyte solution. When CO enters the sensor, it undergoes a chemical reaction, producing an electrical current proportional to the CO concentration. If the CO level exceeds a predefined threshold, the detector sounds an alarm.

Limitations:

While effective for safety, CO detectors have notable limitations:

- Binary Feedback: They provide a simple alarm/no alarm output without indicating the actual CO concentration.

- Lack of Precision: They are not designed for precise measurements or continuous monitoring.

- Not Suitable for Industrial Use: In industrial settings, where accurate CO measurements are crucial for process control and compliance, these detectors fall short.

Why This Matters:

In environments like manufacturing plants or laboratories, understanding exact CO levels is vital. Relying solely on basic CO detectors in such settings can lead to undetected hazards or non-compliance with safety regulations.

While CO detectors are indispensable for residential safety, they are not equipped to handle the demands of industrial applications where precise CO monitoring is essential.

Why Do Industries Use Carbon Monoxide CO Gas Analyzer Instead of CO Detector?

Unlike basic detectors, these analyzers, such as ESEGAS CO gas analyzers IR-GAS-600, provide precise, real-time measurements of CO concentrations, enabling informed decision-making and efficient operations.

Advanced Detection Technologies

CO gas analyzers employ sophisticated technologies to achieve high accuracy and reliability:

- Non-Dispersive Infrared (NDIR) Sensors: NDIR technology measures gas concentrations by detecting the absorption of infrared light, providing stable and accurate readings over a wide concentration range.

- Tunable Diode Laser Absorption Spectroscopy (TDLAS): TDLAS method uses laser light to detect specific gas molecules, offering high sensitivity and selectivity for CO detection, enabling real-time measurements even at low concentrations and in complex gas mixtures.

These technologies enable continuous monitoring across a wide concentration range, from parts per million (ppm) to percentage levels, ensuring accurate detection in various industrial applications.

Industrial Applications

CO gas analyzers are vital in numerous industries:

- Metallurgy: Monitoring CO levels in furnaces and kilns to optimize combustion and ensure worker safety.

- Power Generation: Controlling emissions and enhancing efficiency in power plants by tracking CO concentrations in flue gases.

- Cement Production: Ensuring compliance with environmental standards by measuring CO emissions during cement manufacturing processes.

- Chemical Manufacturing: Maintaining product quality and process safety by monitoring CO levels in chemical reactions.

For example, ESEGAS’s IR–GAS–600 series offers an NDIR CO channel with a range of 0–5 % (high resolution 0.01 %, accuracy ≤ ±2 % FS) and logs data via an integrated PLC interface—ideal for continuous operation in gasification or flue-gas monitoring.

CO gas analyzers are not just measurement tools; they are integral components of modern industrial systems, providing the data necessary to maintain safe and efficient operations. Their advanced technologies and capabilities make them essential for industries where precise CO monitoring is critical.

What Are the Key Differences Between a CO Detector and a CO Gas Analyzer?

To make informed decisions about carbon monoxide (CO) monitoring, it’s crucial to understand the distinctions between CO detectors and CO gas analyzers. The following comparison highlights their differences across several key features:

| Feature | CO Detector | CO Gas Analyzer |

| Primary Use | Safety alert for residential and commercial spaces | Precision measurement for industrial process control and compliance |

| Measurement Output | Binary (alarm/no alarm) | Quantitative (exact CO concentration levels) |

| Detection Range | Typically up to 1,000 ppm | From parts per billion (ppb) to percentage levels, depending on the model |

| Sensor Technology | Electrochemical sensors | Advanced technologies like Tunable Diode Laser Absorption Spectroscopy (TDLAS) and NDIR sensors |

| Data Logging | Not available | Available; supports trend analysis and process optimization |

| Installation | Simple wall or ceiling mounting | Requires professional installation; options for portable, extractive, and in-situ setups |

| Maintenance | Low; periodic battery replacement | Regular calibration and maintenance required |

| Application Examples | Homes, offices, schools | Power plants, steel mills, cement factories, chemical manufacturing facilities |

| Example Product | Standard residential CO alarm | ESEGAS CO Gas Analyzer (Models: IR-GAS-600) |

ESEGAS’s CO gas analyzers exemplify the advanced capabilities required in industrial settings. Their models, such as the ESE-IRGAS-600, utilize NDIR technologies to provide accurate, real-time measurements across a broad concentration range. These analyzers support both portable and online monitoring, making them versatile solutions for various industrial applications.

How Do You Choose Between a CO Detector and a CO Gas Analyzer?

Selecting the right carbon monoxide (CO) monitoring device depends on your specific environment and objectives. Here’s a concise guide to help you make an informed decision:

Residential and Commercial Settings: Prioritize Safety

In homes, offices, and public spaces, the primary concern is the immediate detection of hazardous CO levels to protect occupants. CO detectors are designed for this purpose:

- Immediate Alerts: They sound alarms when CO concentrations reach dangerous levels, enabling prompt evacuation.

- Ease of Use: Typically battery-operated and easy to install without professional assistance.

- Cost-Effective: Affordable solutions for ensuring occupant safety.

However, they provide limited information, offering only binary feedback (alarm/no alarm) without detailed concentration data.

Industrial Applications: Demand Precision and Compliance

In industrial settings, carbon monoxide (CO) gas analyzers are indispensable tools for ensuring safety, optimizing processes, and complying with environmental regulations.CO gas analyzers are suited for these needs:

- Accurate Measurements: Provide real-time, quantitative data across a broad concentration range.

- Continuous Monitoring: Enable ongoing assessment of CO levels, critical for maintaining operational efficiency.

- Data Logging: Facilitate trend analysis and reporting for compliance purposes.

ESEGAS: A Reliable Choice for Industry

For industries requiring accurate CO monitoring, ESEGAS offers advanced solutions:

- ESE-IRGAS-600: Employs Non-Dispersive Infrared (NDIR) sensors for reliable CO measurement.

- ESE-FTIR-100: Owns FTIR technology for CO and more gases monitoring in one unit.

These analyzers accommodate a wide measurement range, from parts per million (ppm) to percentage levels, and are available in portable and online models with options for extractive and in-situ installation. Their robust design ensures suitability for harsh industrial environments.

Conclusion

Choosing a CO detector for basic safety in homes and businesses, and opt for a CO gas analyzer, like those from ESEGAS, for comprehensive monitoring in industrial settings.

If you want to know more, contact with us please!