Syngas analyzers play a crucial role in the oil and gas industry, helping businesses enhance operational efficiency and ensure safety. But how do they exactly contribute to the sector?

The oil and gas industry is one of the most energy-intensive sectors globally. As production processes become more complex, ensuring that everything runs efficiently and safely is a top priority. One tool that has become indispensable in this quest is the syngas analyzer. This instrument is crucial for monitoring the composition of syngas, which is a vital component in energy production and refining processes. By accurately measuring the concentrations of gases like carbon monoxide (CO), hydrogen (H2), and carbon dioxide (CO2), syngas analyzers help optimize operations, improve safety standards, and meet environmental regulations.

Syngas analyzers are essential in monitoring and analyzing the composition of syngas in oil and gas operations. They help optimize production processes and ensure compliance with safety standards.

In the high-stakes world of oil and gas, a syngas analyzer is not just a luxury—it’s a necessity. These devices provide real-time data that allows operators to adjust processes instantaneously, preventing inefficiencies or even dangerous situations from escalating. As production processes are often carried out under extreme conditions, understanding the exact composition of syngas becomes critical for maintaining optimal operational efficiency.

But how exactly do syngas analyzers work in the oil and gas industry?

While many know about gas analyzers, not everyone understands the specific role of syngas analyzers. So, let’s delve deeper into how they function and why they are so vital to the industry.

What is Syngas, and Why is It Important in Oil and Gas Operations?

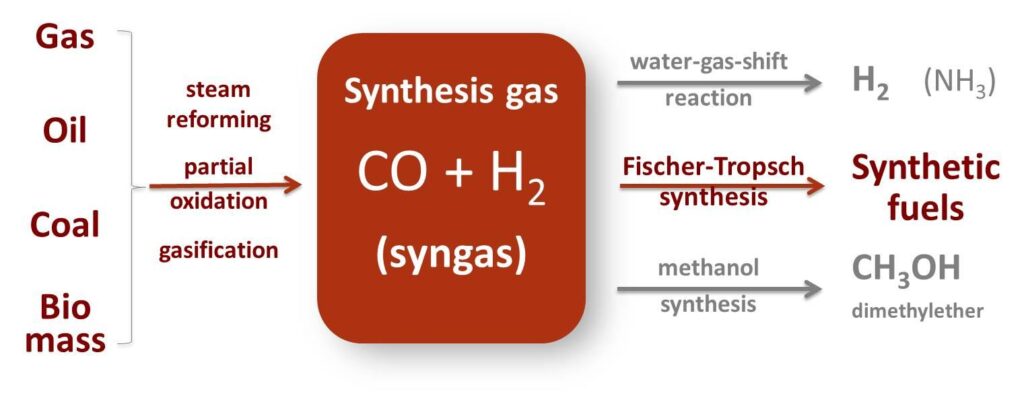

Syngas, or synthetic gas, is a mixture of carbon monoxide (CO), hydrogen (H2), and carbon dioxide (CO2), and it is often produced from natural gas, coal, or biomass. In the oil and gas industry, syngas serves as an essential building block for various processes. For example, syngas is a critical component in hydrogen production, which is later used in refining crude oil into high-quality fuels. It’s also used to produce methanol and other valuable chemicals, making it central to numerous downstream processes.

Given that syngas is an intermediary in many production steps, knowing its exact composition helps operators fine-tune refining methods. If the syngas composition isn’t right, it can lead to inefficient reactions, wasted energy, and the production of undesirable by-products. Syngas analyzers offer real-time data on the concentrations of gases like hydrogen and carbon monoxide, ensuring that the ratios remain optimal for production.

Moreover, syngas analysis also allows refineries to manage energy consumption more effectively. By closely monitoring syngas output, they can make the necessary adjustments to fuel production and maximize efficiency across operations.

How Does a Syngas Analyzer Work in Oil Refining?

One of the key applications of syngas analyzers in the oil and gas industry is their role in refining processes. In a typical oil refinery, syngas is produced as part of the process of converting hydrocarbons into usable fuels like gasoline, diesel, and jet fuel. Hydrogen produced from syngas is especially important in refining because it is used in processes like hydrocracking and desulfurization.

Syngas Analyzer

A syngas analyzer works by continuously measuring the concentrations of gases like hydrogen, carbon monoxide, and carbon dioxide in real-time. This data helps adjust process conditions to optimize syngas usage. For instance, if hydrogen concentration is too low, the analyzer alerts operators to adjust the steam-to-carbon ratio or other parameters to boost hydrogen production.

Real-time monitoring helps operators optimize the syngas conversion process, maximizing valuable fuel production and minimizing waste. The precise data from syngas analyzers also allows refineries to adjust operations based on current needs, ensuring production aligns with demand.

How Does a Syngas Analyzer Contribute to Safety in Oil and Gas Operations?

Safety is paramount in the oil and gas industry, where hazardous gases are frequently present in production environments. This is where syngas analyzers come into play. These devices help prevent dangerous situations by continuously monitoring the levels of harmful gases like carbon monoxide and hydrogen, which are flammable and pose health risks.

For instance, carbon monoxide (CO) is colorless, odorless, and highly toxic. If left unchecked, an increase in CO levels could lead to life-threatening conditions or even explosions. A syngas analyzer helps mitigate such risks by triggering alarms when gas concentrations reach unsafe levels, allowing operators to take action immediately.

Furthermore, hydrogen, which is a major component of syngas, is highly flammable. Monitoring hydrogen levels is critical to ensure that it doesn’t accumulate to dangerous concentrations that could lead to fires or explosions. By maintaining safe levels of hydrogen, carbon monoxide, and other gases, syngas analyzers play a significant role in ensuring the safety of workers and equipment on site.

How Does a Syngas Analyzer Impact Environmental Compliance?

In today’s environmentally-conscious world, adhering to regulations is not just a legal requirement but a business imperative. The oil and gas industry is under constant scrutiny for its environmental impact, and syngas analyzers help companies comply with emission standards by providing real-time data on gas emissions.

Regulations like the Clean Air Act set strict limits on pollutants like CO2 in the oil and gas industry. Syngas analyzers provide continuous data on gas composition, helping operators monitor and control emissions. This allows timely interventions if emissions approach unsafe levels.

By accurately measuring syngas composition, these analyzers also help oil and gas companies reduce their carbon footprint. As the industry seeks to adopt more sustainable practices, real-time syngas analysis enables companies to make operational adjustments that reduce environmental damage, while still meeting production targets.

Furthermore, the data generated by syngas analyzers can be used for environmental reporting, making it easier for oil and gas operators to demonstrate compliance with local and international environmental standards.

What Are the Key Benefits of Using a Syngas Analyzer in the Oil and Gas Industry?

The benefits of using a syngas analyzer extend beyond optimizing production processes and ensuring safety. These devices also offer significant advantages in terms of operational efficiency and cost savings.

1. Increased Operational Efficiency:

By providing real-time data on syngas composition, these analyzers allow operators to make immediate adjustments to production processes. This ensures that resources are used efficiently, reducing waste and improving overall output.

2. Cost Savings:

With accurate measurements, syngas analyzers help optimize the use of expensive raw materials and energy. This not only reduces costs associated with excess production but also helps prevent unnecessary downtime caused by equipment failure or unsafe gas concentrations.

3. Improved Safety:

The ability to monitor dangerous gases like carbon monoxide and hydrogen in real-time ensures that operators can take preventive measures before dangerous situations arise. This reduces the risk of accidents, protecting both personnel and assets.

4. Regulatory Compliance:

Syngas analyzers help ensure that operations comply with strict environmental regulations by offering detailed reports on emissions and gas concentrations. This prevents fines and reputational damage, and positions the company as a responsible environmental steward.

Conclusion

Syngas analyzers are indispensable tools in the oil and gas industry, offering a wide range of benefits. From improving operational efficiency to ensuring safety and environmental compliance, these devices help operators optimize refining processes, reduce costs, and maintain a safe working environment. As the demand for cleaner, more efficient energy sources grows, syngas analyzers will continue to play a key role in transforming the oil and gas industry for the better.