Industrial operations today face growing demands for safety, environmental compliance, and operational efficiency. Yet traditional gas detection systems often fall short in accuracy, response time, and reliability—especially when measuring complex process or emission gases. The result? Regulatory risk, inefficiencies, and safety blind spots that threaten production integrity. NDIR analyzers solve this by delivering precise, continuous, and reliable detection of key gases.

NDIR analyzers—short for Non‑Dispersive Infrared Gas Analyzers(NDIR Gas Analyzer)—are advanced optical instruments that measure gas concentrations using infrared absorption characteristics. By targeting specific wavelengths absorbed by CO₂, CO, CH₄, and other gases, NDIR analyzers provide robust, interference‑resistant measurements critical to industrial emissions monitoring, process optimization, and safety compliance.

As industries adopt smarter gas sensing technologies, it’s vital to understand how NDIR analyzers work and why they matter—especially when choosing a trusted partner like ESEGAS for your monitoring solutions. Below, we break down what NDIR is, how it operates, and where it delivers the most value.(Gas Analyzer Manufacturers)

How Do NDIR Gas Analyzers Work?

At their core, NDIR analyzers exploit a simple physical principle: each gas absorbs infrared (IR) light at characteristic wavelengths. An NDIR system projects IR light through a sample gas cell; gases such as CO₂, CO, or CH₄ absorb light at distinct frequencies. By comparing the intensity of light before and after it passes through the gas, the analyzer quantifies the gas concentration with high precision.

Unlike electrochemical or catalytic sensors, NDIR does not consume the target gas, enabling stable long‑term readings with minimal drift. This makes NDIR ideally suited for continuous monitoring in industrial environments where consistent precision is mandatory.

Which Gases Can NDIR Gas Analyzer Detect?

NDIR analyzers excel in measuring gases with strong IR absorption spectra, including:

1. Carbon Dioxide (CO₂)

One of the most widely monitored gases in industrial and environmental settings, CO₂ has strong IR absorption bands near 4.26 µm. NDIR is the gold standard for CO₂ analyzer applications due to its precision and long-term stability.

Applications:

- Combustion efficiency control (boilers, furnaces)

- Indoor air quality monitoring

- Greenhouse gas measurement

- Carbon capture systems

At ESEGAS, products like the IR-GAS-600 series integrate dedicated CO₂ channels for precise ppm to vol.% level analysis, ensuring compliance with stringent emissions standards.

2. Carbon Monoxide (CO)

Carbon monoxide absorbs IR radiation around 4.6 µm, making it an ideal target for NDIR detection. Since CO is toxic even at low concentrations and often co-exists with CO₂ in combustion and exhaust streams, accurate monitoring is vital.

Applications:

- Flue gas analysis in power plants

- Industrial process control

- Workplace safety in enclosed environments (e.g. tunnels, garages)

ESEGAS analyzers with CO detection modules are engineered with dual-beam IR paths and auto-zero functionality to provide drift-free, real-time readings even in high-humidity or dust-prone conditions.

3. Methane (CH₄)

Methane, a potent greenhouse gas and a key energy source, shows strong IR absorption around 3.3 µm. It is often monitored in biogas plants, natural gas infrastructure, and landfill operations.

Applications:

- Leak detection in oil & gas

- Biogas purity monitoring

- LNG and CNG process oversight

- Underground coal mines

ESEGAS systems like the Portable Gas Analyzer offer CH₄ channels with fast response times and rugged sensor housings for reliable field performance.

4. Nitrous Oxide (N₂O)

Though less commonly monitored, N₂O is gaining attention due to its environmental impact and IR activity near 4.5 µm. NDIR can be configured to detect this gas in specialty applications.

Applications:

- Greenhouse gas tracking in agriculture

- Anaesthesia gas monitoring in medical settings

- Semiconductor manufacturing exhaust

ESEGAS offers custom-configured NDIR analyzers for niche gases like N₂O in partnership with OEM clients.

5. Sulfur Hexafluoride (SF₆)

SF₆ is an extremely potent greenhouse gas used in the electrical industry as an insulator in switchgear. It has detectable IR absorption bands in the mid-infrared range.

Applications:

- Leak detection in high-voltage equipment

- Gas-insulated switchgear (GIS) diagnostics

- SF₆ recovery systems

NDIR detection provides a safe and efficient method to monitor SF₆ levels without the risks associated with chromatographic sampling or chemical reagents.

6. Hydrocarbons and VOCs

Many hydrocarbons—including propane, butane, and isobutane—as well as selected volatile organic compounds (VOCs), exhibit IR activity and can be detected with NDIR analyzers configured with broadband or multi-channel detectors.

Applications:

- Petrochemical refining

- Fuel storage monitoring

- Ambient air pollution control

ESEGAS supports hydrocarbon analysis with flexible sensor configurations tailored to both ppm and % level detection, based on the customer’s process needs.

Why Choose NDIR Gas Analyzers Over Other Technologies?

Industrial users often weigh several gas detection technologies—NDIR, tunable diode laser absorption spectroscopy (TDLAS), electrochemical sensors, and more.

NDIR stands out for:

- High stability: Optical measurement doesn’t degrade the sample or sensor over time.

- Low interference: Infrared absorption is specific to each gas’s molecular signature, reducing false positives.

- Wide dynamic range: From trace levels to percent–level concentrations, NDIR adapts to many processes.

These advantages make NDIR ideal for continuous emissions monitoring systems, combustion control, and regulatory compliance where accuracy and uptime are non‑negotiable.(GII)

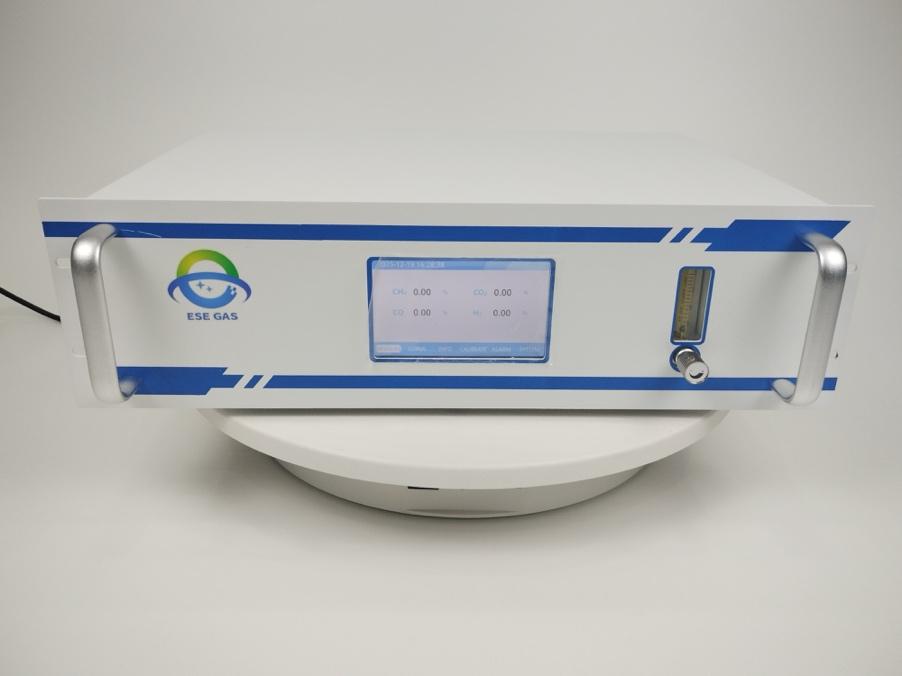

ESEGAS NDIR Products: Precision Meets Practical Performance

At ESEGAS, our gas analyzer portfolio includes advanced NDIR‑based solutions engineered for industrial excellence. Our systems combine durability, accuracy, and flexibility across applications—from emissions monitoring to process gas analysis.(Gas Analyzer Manufacturers)

ESEGAS offers trace gas analyzers like the IR‑GAS‑600 series—using dual‑beam NDIR to measure CO, CO₂, and CH₄ simultaneously with ultra‑high stability and reliability. These systems serve demanding environments such as gasification plants, steel mills, and biomass processing.(Gas Analyzer Manufacturers)

Where Are NDIR Gas Analyzers Used?

1. Emission Monitoring & Regulatory Compliance

Factories, power plants, incinerators, and refineries must continuously report emissions. NDIR analyzers deliver real‑time data on regulated pollutants, helping companies stay compliant with national and international air quality standards while minimizing penalties.

2. Industrial Process Control

In combustion systems, furnaces, and boilers, controlling fuel‑to‑air ratios directly impacts energy efficiency. NDIR measurements of CO and CO₂ inform combustion adjustments that reduce fuel costs and improve operational stability.

3. Safety & Leak Detection

Many industrial environments—chemical plants, petrochemical refineries, and wastewater treatment facilities—contain gases hazardous to workers. NDIR analyzers monitor potential leaks and high‑risk zones, enhancing occupational safety programs.

4. Environmental & Climate Monitoring

NDIR systems are widely used for monitoring greenhouse gases like CO₂ and CH₄, supporting corporate sustainability initiatives and carbon accounting efforts.(GII)

Integrating NDIR Into a Broader Gas Monitoring Strategy

While NDIR excels in many scenarios, sophisticated monitoring ecosystems may combine it with other technologies when needed. For example, ESEGAS delivers multi‑technology solutions that integrate NDIR, UV‑DOAS, and TDLAS for complex emission stacks or challenging industrial conditions—ensuring complete coverage across targeted gases.(Gas Analyzer Manufacturers)

Conclusion: NDIR Analyzers Are a Cornerstone of Modern Gas Monitoring

In today’s industrial landscape, precision, reliability, and responsiveness are no longer optional—they’re essential. NDIR analyzers deliver all three by leveraging the physics of infrared absorption to provide accurate, stable gas measurements across a spectrum of applications. With industry‑proven products like those from ESEGAS, you gain both technological performance and the partnership needed to meet evolving regulatory and operational challenges.

Let us help you choose the right NDIR solution and take your gas monitoring strategy to the next level.(Gas Analyzer Manufacturers)