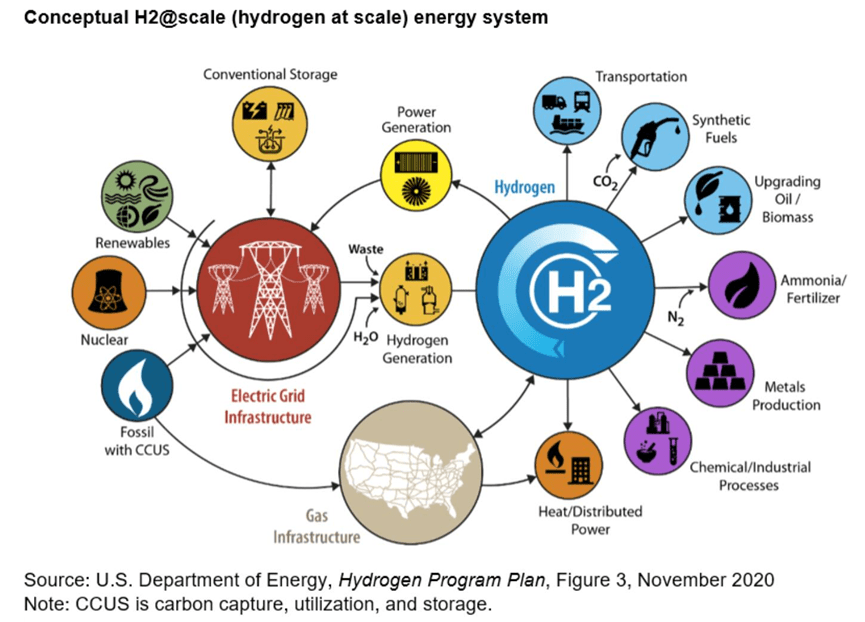

As the problem of climate change becomes increasingly serious and the demand for clean energy continues to grow, hydrogen energy has become a high-profile energy option. As an efficient and clean energy source, hydrogen is being widely used in fuel cells, chemical industry, industrial production and other fields. However, to ensure the safe use and efficient utilization of hydrogen, trace gas detection has become crucial. This article will focus on the importance of trace gas detection in H2 energy applications, paying special attention to some key trace gases such as carbon monoxide (CO) and ammonia (NH3).

Part One: Generation of Hydrogen

The generation of hydrogen is the initial stage of hydrogen energy and is usually achieved through methods such as water electrolysis or natural gas steam reforming. However, carbon monoxide (CO) may be produced as a by-product during this process. CO is a colorless, tasteless, and odorless gas, but it is harmful to humans and the environment, so trace gas detection is required to ensure the purity of the hydrogen produced.

Carbon monoxide (CO) detection

Carbon monoxide is a colorless, tasteless, and odorless gas, but it is an extremely dangerous gas. In H2 energy applications, carbon monoxide may be produced due to some imperfect reactions in the production, storage and transmission of hydrogen. Carbon monoxide can cause serious harm to the human body because it binds to hemoglobin and reduces the oxygen-carrying capacity of the blood, leading to poisoning and even death.

CO gas analyzers are widely used in industrial fields for a variety of applications, including:

- Metallurgical industry

- Coking industry

- Power industry

- Cement industry

- Ammonia production.

They provide accurate and reliable measurements for monitoring the concentration of CO emission gases. By using these instruments, producers can ensure that their plants comply with emissions standards as well as maximize their product output and efficiency. Furthermore, CO gas analyzers can also be used to optimize the combustion process in order to reduce energy consumption and emissions while improving product quality. With its advanced features, these instruments offer a convenient way for industries to achieve sustainable production goals. Thus, they provide an essential tool for the efficient functioning of today’s industrial operations.

Therefore, trace gas detection of carbon monoxide becomes critical. Detection methods usually include chemical sensors, infrared absorption spectroscopy and gas chromatography. These methods can quickly and accurately detect trace levels of carbon monoxide, ensuring that hydrogen is produced and used without danger.

Part 2: Storage of Hydrogen

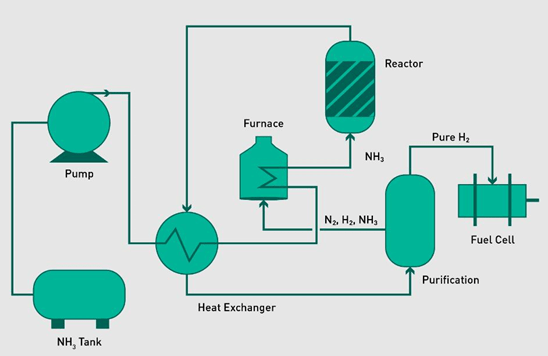

Hydrogen needs to be safely and reliably maintained in its purity during storage. During hydrogen storage, Ammonia (NH3) may also be used as a carrier for hydrogen, so the detection of NH3 is also of great significance.

Ammonia (NH3) detection

Ammonia is another common trace gas that plays an important role in H2 energy applications. Ammonia is commonly used as a nitrogen source in hydrogen production processes. However,High concentrations of ammonia can be irritating and dangerous to the human body, so trace gas detection is required to ensure safety.

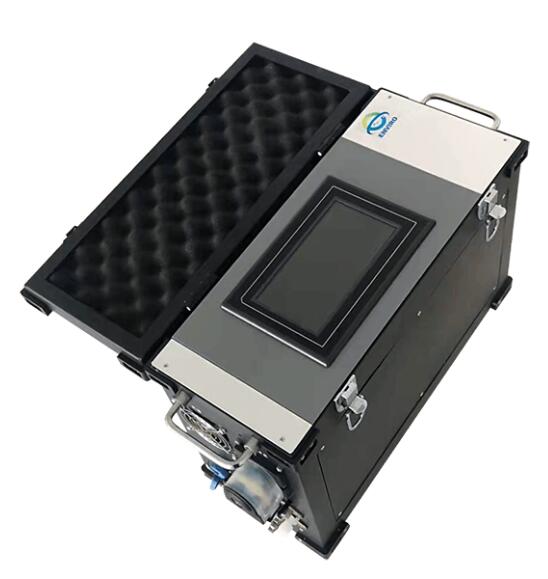

Ammonia TDLAS gas analyzers are widely used in industries such as agriculture, environmental monitoring, chemical plants, and food processing, where accurate and reliable measurement of ammonia concentrations is crucial for safety, process control, and compliance with regulations.

Here are some key advantages of using an ammonia TDLAS gas analyzer:

- High Selectivity: TDLAS technology provides high selectivity for the target gas, in this case, ammonia. The analyzer utilizes a laser diode that emits light at a specific wavelength corresponding to the absorption line of ammonia. This allows for accurate and specific measurements of ammonia concentration, even in the presence of other gases.

- Wide Dynamic Range: TDLAS gas analyzers offer a wide dynamic range, enabling measurements across a broad range of ammonia concentrations. They can accurately measure low parts-per-billion (ppb) levels up to high parts-per-million (ppm) concentrations, making them suitable for a variety of applications.

- Fast Response Time: TDLAS gas analyzers provide rapid response times, allowing for real-time monitoring of ammonia levels. The inherent speed of the laser-based measurement technique enables quick detection and measurement of ammonia concentration changes, facilitating prompt action or intervention if needed.

- Non-Intrusive and Remote Sensing: TDLAS gas analyzers are non-intrusive, meaning they do not require direct contact with the gas sample. The laser beam is typically directed through a sampling cell or pipe, allowing for remote sensing of the ammonia gas. This feature is beneficial for continuous monitoring applications or situations where direct access to the gas stream is challenging.

- High Accuracy and Precision: TDLAS gas analyzers offer high accuracy and precision in measuring ammonia concentrations. The narrow linewidth of the laser source and the use of sophisticated spectral analysis algorithms result in precise measurements, ensuring reliable and consistent data.

- Low Maintenance and Long-Term Stability: TDLAS gas analyzers often have minimal moving parts and require little maintenance. They offer long-term stability and robustness, reducing the need for frequent calibration and minimizing downtime.

- Compact and Modular Design: Ammonia TDLAS gas analyzers are available in compact and modular designs, making them suitable for various installation requirements. They can be integrated into existing monitoring systems or deployed as standalone units in different locations.

Trace ammonia detection typically uses methods such as chemical sensors or gas chromatography. These methods can quickly detect ammonia concentrations and trigger alarms or take action to prevent ammonia from leaking or exceeding safety limits. Ammonia detection is one of the key steps to maintain safety during hydrogen production and storage.

Part 3: Use of Hydrogen

As a clean and efficient energy source, hydrogen has broad application prospects, covering multiple areas including fuel cells, industrial production and transportation. In these applications, trace gas detection plays a key role in helping to ensure hydrogen safety, performance optimization and regulatory compliance.

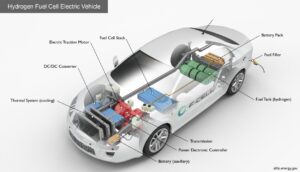

- Fuel cell applications

- Fuel cells are a technology that converts hydrogen into electricity, which is used to drive electric vehicles, provide backup power, and more. In fuel cells, the purity of hydrogen is critical to ensure efficient operation of the cell.

- Trace gas detection: By implementing trace gas detection in the fuel supply chain, impurities in hydrogen, such as CO, NH3, etc., can be monitored to ensure that pure hydrogen enters the fuel cell, prevents battery clogging or damage, and improves battery life and performance.

- Industrial production

- Hydrogen is widely used in industrial production and is used in hydrogen welding, hydrogen reduction and other processes. In these industrial applications, the detection of trace gases is crucial to the control and safety of the production process.

- Trace gas detection: Trace gas detection in industrial production can be used to monitor impurities in hydrogen to ensure the safety and efficiency of industrial processes. For example, detecting CO concentration in hydrogen can prevent fire and explosion risks.

- Transportation

- Hydrogen fuel cell vehicles are a clean transportation solution, but the quality and safety of hydrogen need to be ensured to promote its use.

- Trace gas detection: In hydrogen filling stations and hydrogen storage equipment, trace gas detection can be used to monitor the purity and impurities of hydrogen to ensure that the hydrogen added to the vehicle fuel tank is safe and of high quality. This helps increase consumer trust in hydrogen fuel cell vehicles.

- Regulatory requirements

- Many countries and regions have formulated regulatory requirements for hydrogen systems, including hydrogen quality standards, safety requirements, etc. Trace gas detection can help companies comply with these regulations and ensure compliance of their hydrogen systems.

- Regulatory compliance: The use of trace gas detection methods can help hydrogen-related companies meet regulatory requirements, reduce possible legal risks, and improve their competitiveness in the market.

Trace gas detection plays a key role in various hydrogen applications, whether in ensuring the purity and safety of hydrogen, or in optimizing performance and complying with regulations. The continuous innovation and development of these detection methods will further promote the sustainable development of hydrogen energy and encourage more industries to adopt hydrogen as a clean energy option. With the advancement of technology, trace gas detection will become more accurate, real-time and reliable, creating more opportunities for the widespread application of hydrogen energy and helping the world address energy and environmental challenges.

Development of Trace Gas Detection Technology

With the continuous advancement of science and technology, trace gas detection technology is also developing continuously. New sensors and instruments make gas detection more accurate, sensitive and faster. For example, the application of nanomaterials makes it easier for sensors to detect trace gases, while reducing the size and energy consumption of instruments. In addition, smart technologies such as drones and robots are also used for gas detection tasks, improving detection efficiency and safety.

In H2 energy applications, the continuous advancement of trace gas detection technology provides strong support for the safe production and use of hydrogen. By monitoring trace gas concentrations in real time, timely measures can be taken to prevent accidents and ensure the reliability and sustainability of H2 energy.

Conclusion

Trace gas detection plays a vital role in H2 energy applications. The detection of trace gases such as carbon monoxide and ammonia can ensure the safe production and use of hydrogen, prevent accidents, and improve the reliability and sustainability of energy. With the continuous development of technology, trace gas detection methods will become more accurate, faster and intelligent, providing strong support for the development of clean energy.

Therefore, in the application of H2 energy, we not only need to pay attention to the production and utilization technology of hydrogen itself, but also need to pay attention to the research and application of trace gas detection technology to ensure the sustainable development of hydrogen energy and provide a cleaner environment and human health. and reliable energy options.

If you have any questions, please feel free to contact us!