In industrial settings, precise monitoring of process gases is crucial for operational efficiency, safety, and regulatory compliance. Non-dispersive infrared (NDIR) technology has emerged as a pivotal tool in enhancing the accuracy and reliability of gas analysis. This article delves into the fundamentals of process gases and elucidates how NDIR technology optimizes their monitoring. Understanding the intricacies of process gases and the advantages of NDIR technology can significantly enhance industrial operations. Let’s explore these aspects in detail.

What Are Process Gases and Their Role in Industrial Applications?

Process gases play critical roles in industrial manufacturing. Industries use or generate process gases during operations to accelerate chemical reactions, optimize production efficiency, and maintain controlled environmental conditions. Additionally, they often act as chemical intermediates, enabling complex material transformations across manufacturing stages. Let’s examine six critical process gases powering modern manufacturing and energy systems.

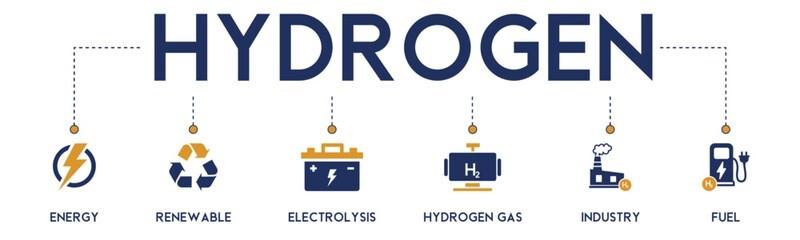

- Hydrogen (H2): It stands out for its dual energy and refining roles.

—The petrochemical sector utilizes H₂ for hydrocracking heavy oils.

—The fuel cell technology leverages its clean combustion properties.

—Metallurgical applications particularly benefit from hydrogen’s reducing capabilities in metal treatment processes.

(Hydrogen)

- Nitrogen (N2): It dominates inert gas applications across multiple sectors.

—Chemical plants deploy N₂ to prevent explosive atmospheres during volatile reactions. —Food processors use nitrogen flushing to extend product shelf life.

—Semiconductor manufacturers also depend on ultra-pure nitrogen for oxidation-free wafer production.

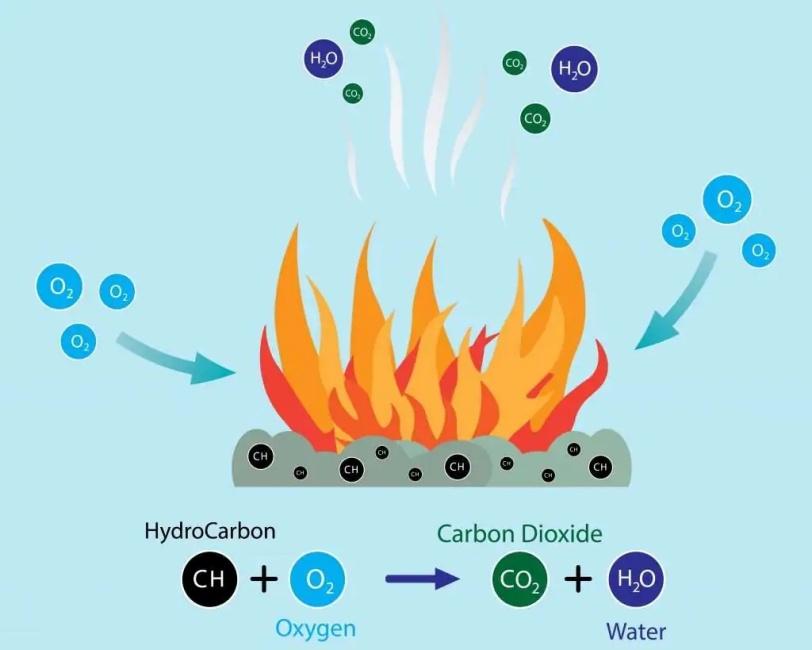

- Oxygen (O2): It remains indispensable for thermal processes requiring precise combustion control.

—Steelmakers inject O₂ into blast furnaces to enhance combustion efficiency.

—Wastewater treatment plants employ oxygen aeration for biological degradation. —Medical oxygen systems represent a critical secondary application of this life-sustaining gas.

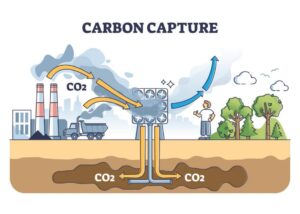

- Carbon dioxide (CO2): It serves both industrial and commercial functions through its unique phase-change properties.

—Food-grade CO₂ carbonates beverages.

—Industrial dry ice applications enable cryogenic cleaning.

—Welding operations utilize carbon dioxide shielding gas to prevent metal contamination during arc processes.

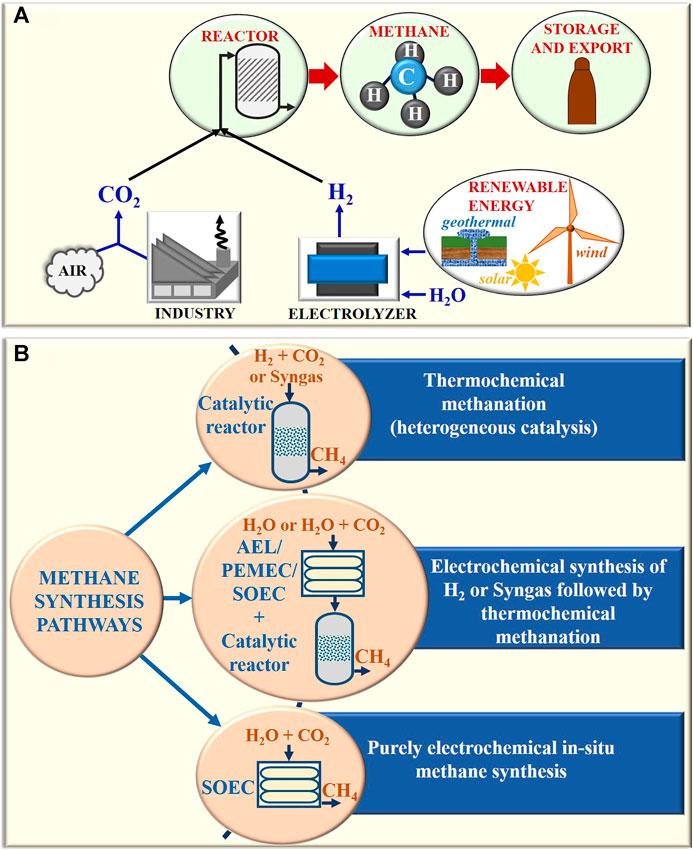

- Methane (CH4): It drives global energy systems through power generation and heating applications.

—Petrochemical converters process CH₄ into hydrogen and acetylene derivatives, creating building blocks for plastics and synthetic materials.

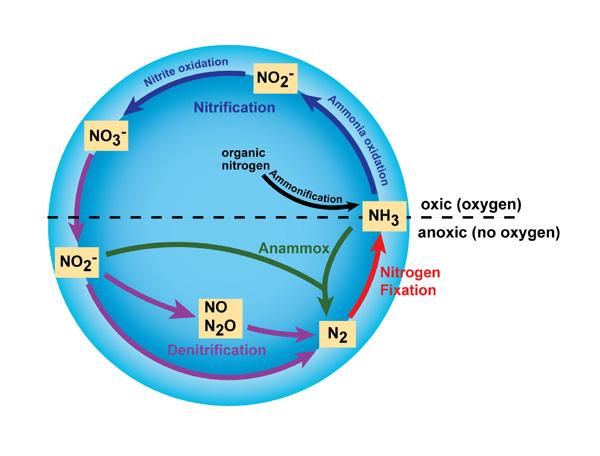

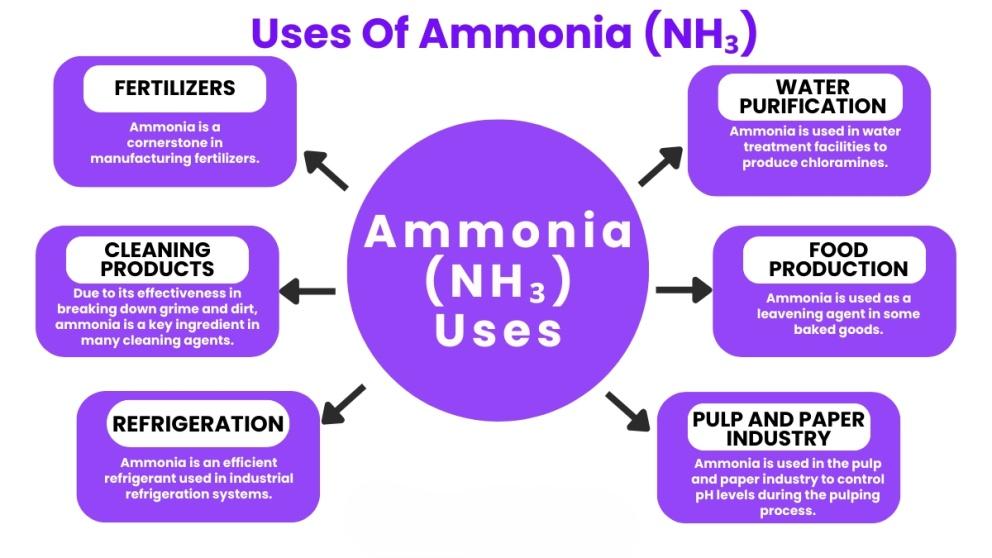

- Ammonia (NH3): It completes this essential group through its dual industrial-agricultural applications.

—Large-scale refrigeration systems use NH₃’s thermodynamic properties for heat transfer.

—Fertilizer production consumes over 80% of global ammonia output to meet agricultural demands.

—Emerging applications include ammonia as a hydrogen carrier in renewable energy.

How Do Industries Produce and Store Process Gases Efficiently?

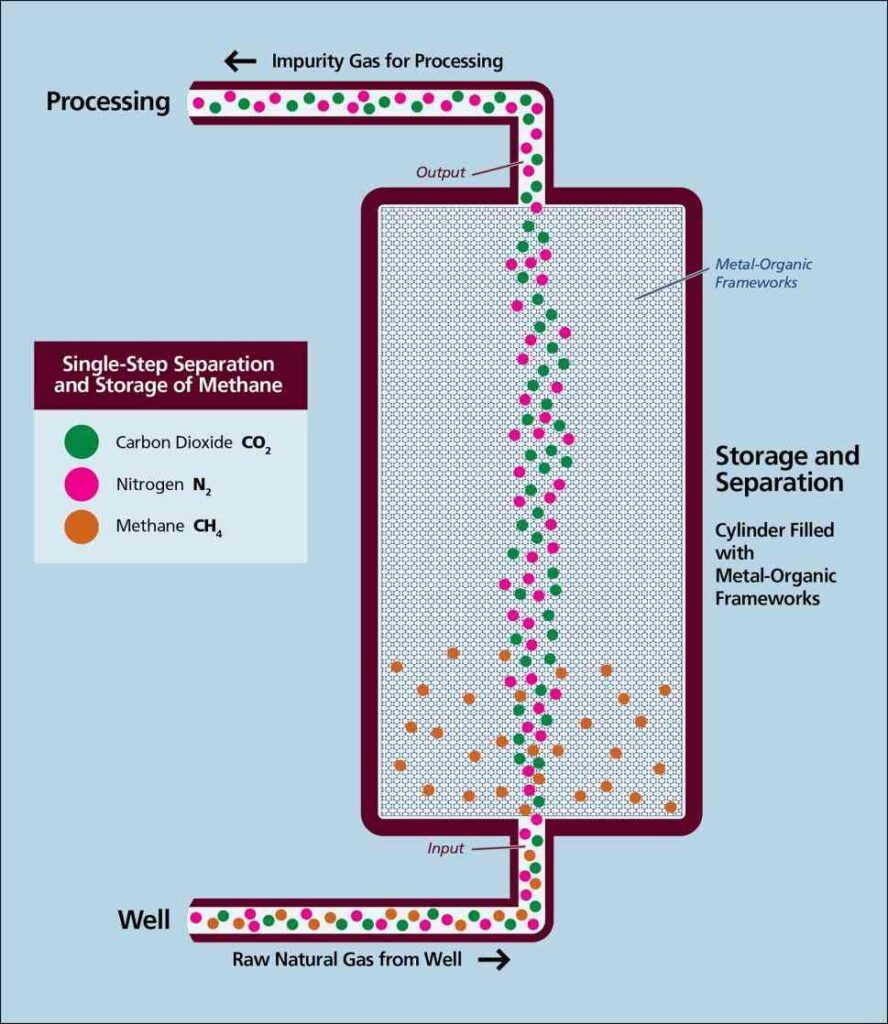

Process gases are produced through various methods, such as chemical synthesis or gas separation techniques, and are stored in pressurized cylinders or specialized storage systems. Controlling emissions involves technologies like scrubbers, flares, or catalytic converters. Proper handling requires safety precautions, including leak detection systems, ventilation, and personal protective equipment.

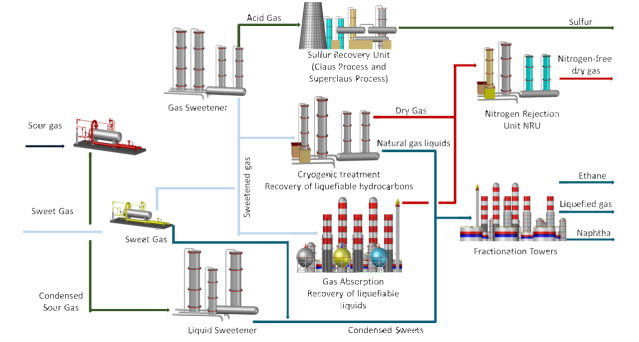

(Seperation & storage of Methane)

- Production Methods: —First, industries generate process gases through chemical synthesis, such as hydrogen via water electrolysis.

—Second, they isolate gases like nitrogen using cryogenic distillation of ambient air.

- Storage Solutions: To store these gases, companies prioritize high-pressure cylinders for portability. For bulk storage, cryogenic tanks maintain gases like oxygen in liquid form at ultra-low temperatures. Alternatively, on-site generation systems enable continuous supply while minimizing logistical risks.

- Key Considerations:

Understanding these production and storage methods is essential for optimizing industrial operations and ensuring safety protocols. For instance, electrolysis-derived hydrogen supports clean energy applications, while cryogenic storage ensures stability for large-scale usage.

How Do Process Gas Drive Efficiency in Petrochemical, Pharmaceutical, and Metallurgical Operations?

Process gases critically determine industrial efficiency through their composition and concentration. Specifically, these parameters govern reaction kinetics, final product specifications, and thermal energy requirements across multiple sectors.

For instance, petrochemical plants utilize synthesis gases for catalytic processes, while pharmaceutical manufacturers depend on inerting atmospheres to prevent oxidation. Similarly, metallurgical operations employ purification gases to achieve metal purity standards exceeding 99.9%.

Advanced analytical techniques like laser-based spectroscopy and gas chromatography enable real-time monitoring of these variables. This capability allows operators to adjust gas flow rates dynamically, minimizing feedstock waste and reducing combustion-related energy losses. Recent case studies demonstrate that optimized gas control in ethylene production decreases energy expenditure by 12-18% while maintaining peak polymer quality.

Three critical factors emerge from industry data:

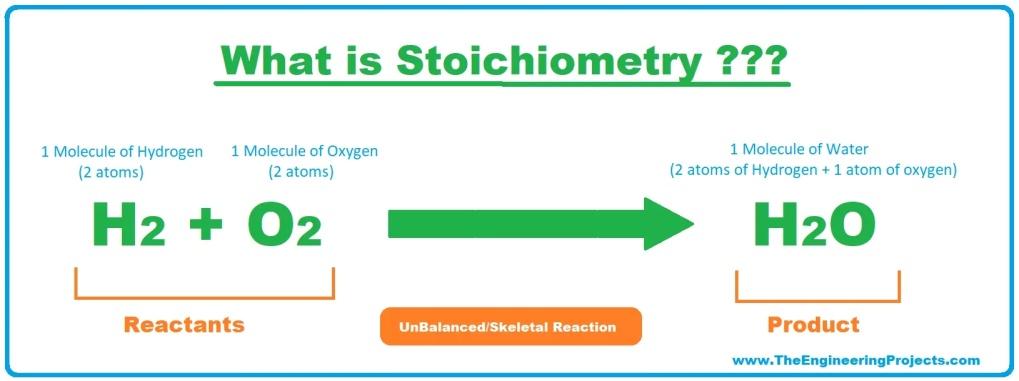

- Precise stoichiometric balancing in synthesis reactions.

2) Maintenance of inert blanket consistency during sensitive processes.

3) Elimination of trace contaminants in purification stages.

Implementing these measures through smart gas delivery systems has shown 20-35% reductions in operational costs for early adopters. The correlation between gas management precision and profit margins continues to strengthen, particularly in high-temperature industrial applications where energy recovery systems interact directly with exhaust gas streams.

What Makes Process Gas Monitoring Essential in Industrial Operations?

Process gas monitoring serves as a frontline defense in industrial environments. First and foremost, it addresses life-threatening risks posed by toxic, flammable, or explosive gases. Continuous monitoring systems detect hazardous chemical releases before they escalate into disasters.

Beyond risk mitigation, this practice directly enhances operational efficiency. Advanced analyzers provide real-time data on gas concentrations, enabling precise adjustments to combustion ratios or reactor conditions. Such optimization minimizes resource waste while maximizing production yields—a critical factor in industries like petrochemicals and semiconductors.

Another critical aspect involves environmental stewardship. Governments globally enforce strict emission limits for volatile organic compounds (VOCs) and greenhouse gases. For instance, the EPA’s Clean Air Act mandates continuous emission monitoring systems (CEMS) to prevent atmospheric contamination. Non-compliance risks hefty fines and reputational damage.

Moreover, proactive gas monitoring boosts financial performance. Identifying pipeline leaks early reduces costly shutdowns and prevents product loss. Infrared spectroscopy and laser-based sensors, for example, help industries cut annual gas consumption by 12–18%, according to 2023 refinery case studies.

In summary, integrating robust gas monitoring solutions isn’t optional—it’s a strategic necessity. From averting catastrophes to aligning with net-zero goals, this practice remains indispensable for sustainable, profitable industrial operations.

How to Choose the Best Process Gas Monitoring Technology? Key Comparisons and NDIR Benefits

Process gas monitoring ensures industrial safety, operational efficiency, and regulatory compliance. Industries use various technologies, each with distinct strengths and limitations. Below, we analyze leading methods and explain why Non-Dispersive Infrared (NDIR) technology often outperforms alternatives.

| Technology | Principle | Advantages | Limitations |

| NDIR (Non-Dispersive Infrared) | Measures absorption of specific infrared wavelengths by gas molecules. | – High selectivity and sensitivity- Non-contact measurement- Low maintenance- Long-term stability | – Limited to gases with distinct infrared absorption features.- Potential interference in mixed gas environments. |

| Electrochemical Sensors | Detect gas concentration through electrochemical reactions producing a current. | – Suitable for detecting toxic gases- Compact and portable- Low power consumption | – Limited lifespan due to sensor degradation-Cross-sensitivity to other gases- Require regular calibration |

| Catalytic Bead Sensors | Measure gas concentration by detecting heat produced during combustion on a heated bead. | – Effective for detecting combustible gases- Robust and durable- Relatively low cost | – Susceptible to poisoning by certain gases- Require oxygen presence- Less effective for low gas concentrations |

| Gas Chromatography (GC) | Separate and analyze gas mixtures based on their interaction with a chromatographic column. | – High-resolution separation- Capable of identifying and quantifying multiple gases simultaneously | – Complex and time-consuming- Requires skilled operation- Not suitable for real-time monitoring |

| Fourier-Transform Infrared (FTIR) Spectroscopy | Analyze absorption of infrared light across a broad spectrum to identify and quantify gases. | – Simultaneously detects multiple gases- Non-destructive analysis- Suitable for complex gas mixtures | – Expensive and bulky equipment- Requires regular maintenance- Longer analysis time compared to NDIR |

If you want to know more detail about NDIR gas analyzers and NDIR systems, visit our website please!

How Can NDIR Technology Enhance Process Gas Monitoring Accuracy and Compliance?

NDIR technology sets new benchmarks in process gas monitoring, delivering exceptional accuracy, reliability, and operational efficiency. As industries increasingly adopt automated systems, integrating NDIR-based gas analyzers becomes critical for compliance with stringent environmental regulations. These systems enable real-time spectral analysis of gas components, ensuring precise leak detection and emission control.