When the wrong Process Gas Analyzer meets the wrong application, you risk safety, compliance, and costly downtime. Learn how to make the right decision—with confidence.

Selecting a process gas analyzer requires evaluating gas composition, environmental conditions, precision needs, and lifecycle cost—aligned with industry regulations and specific process demands.

Choosing the right analyzer is only the first step. To ensure long-term performance, accuracy, and safety, you need to understand what factors really matter—and how to evaluate them smartly.

Why is Selecting The Right Process Gas Analyzer So Critical?

When the wrong analyzer is used in a complex process environment, the consequences can be far-reaching—undetected leaks, incorrect combustion ratios, toxic exposure, or costly regulatory fines. Unfortunately, many facilities underestimate this risk until a failure occurs.

The pain starts with inaccurate data. A mismatched analyzer might not respond correctly to the target gas, may suffer from cross-sensitivity, or deteriorate rapidly under harsh conditions. These errors silently accumulate, leading to poor process control, reduced product quality, and increased energy consumption.

The problem intensifies when compliance and safety are at stake. Process industries such as petrochemical, power generation, and waste treatment are governed by strict emission and safety standards. Failure to meet reporting requirements—due to unreliable gas data—can result in shutdowns, penalties, or worse, safety incidents.

The solution lies in smart selection. Choosing the right process gas analyzer ensures accurate, real-time measurements, enabling operators to optimize combustion, reduce waste, and act immediately on abnormal readings. More than just a tool, a well-matched analyzer becomes a strategic asset in your process.

Reliable data is the foundation of industrial performance. When you select the appropriate analyzer—one engineered for your specific gas, conditions, and application—you build confidence into your operations. That’s why companies turn to trusted suppliers like ESEGAS, who understand not just instruments, but entire process ecosystems.

What are the Key Process Parameters To Consider When Selecting An Analyzer?

Selecting a process gas analyzer is not just about the gas—it’s about the full environment in which that gas exists. To ensure accurate and reliable measurements, engineers must align instrument capabilities with several critical process parameters. Overlooking even one factor can lead to degraded performance, frequent maintenance, or outright failure.

1. Target Gas and Its Chemical Properties

The most fundamental consideration is which gas or gases you are measuring. Is it oxygen, CO₂, NOx, methane, or a VOC mixture? Each gas responds differently to available detection principles—some require infrared (NDIR), others thermal conductivity (TCD), electrochemical cells, or laser-based methods.

Key considerations:

- Molecular weight and polarity

- Absorption spectrum (for optical methods)

- Reactivity with other compounds

- Safety classification (toxic, flammable, inert)

Choosing a technology that matches the chemical behavior of the gas ensures both sensitivity and selectivity.

2. Gas Concentration Range

Every analyzer has a specific detection limit and linearity range. Selecting a device outside that range can lead to unstable readings or data truncation.

You must ask: Are you measuring trace-level gases (ppm or ppb), or bulk concentrations (% levels)? For instance, measuring oxygen in ppm for inerting applications requires much higher sensitivity than monitoring 20.9% ambient air.

A good rule of thumb: select an analyzer with optimal accuracy around your typical operating point, not just your extremes.

3. Pressure and Temperature Conditions

Gas analyzers are calibrated under certain pressure and temperature conditions. But in real-world processes—especially in refining, chemical production, or combustion—the gas might be at high temperature, under vacuum, or pressure.

Temperature and pressure impact:

- Gas density, which affects optical path length or thermal conductivity

- Sensor lifespan and calibration drift

- Required sample conditioning (cooling, pressure regulation, filtration)

A reliable analyzer must either withstand those conditions or work seamlessly with a sample handling system to normalize them.

4. Presence of Interfering Substances

Contaminants such as moisture, dust, acids, hydrocarbons, or other reactive gases can interfere with accurate gas detection. Some sensors are extremely sensitive to water vapor or certain solvents, which can skew readings or degrade sensor components.

In high-contamination environments, analyzers must either feature internal compensation mechanisms (e.g., wavelength filtering) or be paired with gas treatment systems (dryers, filters, scrubbers).

5. Flow Rate and Sampling Dynamics

Is your application continuous, batch, or spot sampling? Does the gas flow directly past the sensor (in-situ) or is it extracted via a probe (extractive)? These factors impact:

- Sensor response time

- Analyzer installation location

- Maintenance needs (e.g., cleaning probes, filters)

For fast-changing processes, response time and lag caused by sample transport can be critical. You need an analyzer that keeps up with the speed of your process.

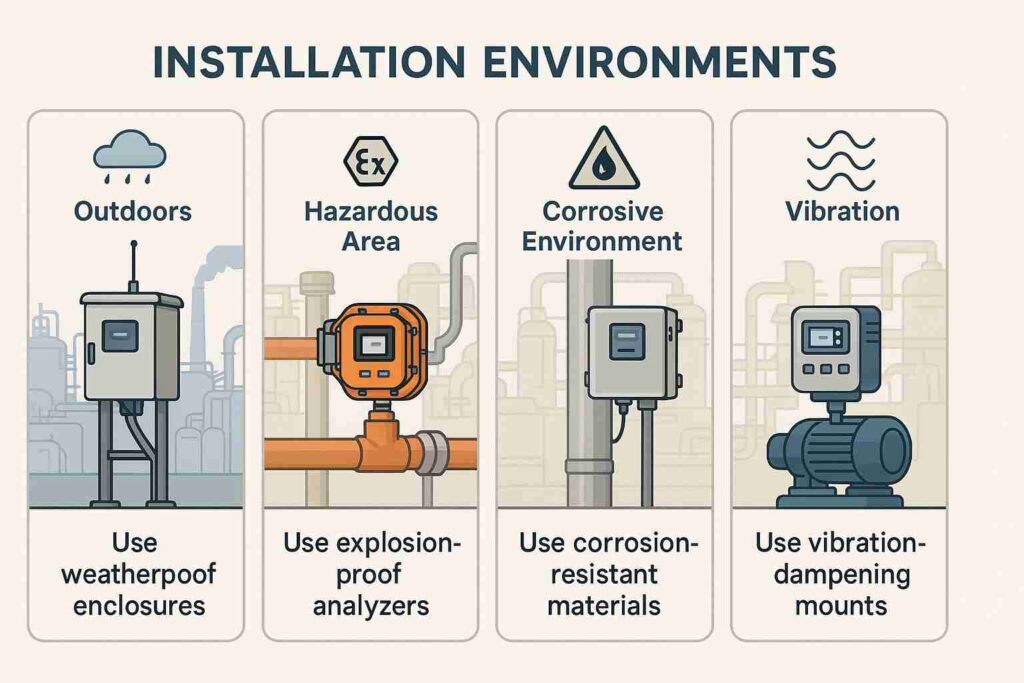

6. Ambient and Installation Environment

Beyond the gas itself, you must also consider the physical environment in which the analyzer will operate. Will it be installed outdoors? In a high-humidity or corrosive zone? In a classified hazardous area (ATEX Zone 1/2)?

This influences:

- Enclosure rating (IP65 or higher)

- Need for explosion-proof housing

- Corrosion-resistant materials (e.g., stainless steel)

- Vibration or thermal shielding requirements

| Parameter | Why It Matters | Typical Considerations | Impact on Analyzer Selection |

| Target Gas & Chemistry | Different gases require different detection technologies | Molecular weight, reactivity, IR absorption, safety class | Choose compatible detection method (NDIR, TCD, FID, etc.) |

| Concentration Range | Analyzer must operate within optimal range for accuracy | ppm, ppb, %, trace vs bulk measurement | Select analyzer with matching detection limit and linear range |

| Pressure & Temperature | Process conditions affect gas density and sensor performance | High-temp flue gas, pressurized vessels, vacuum lines | Requires sampling system or ruggedized analyzer |

| Interfering Substances | Contaminants can skew readings or damage sensors | Moisture, dust, acids, VOCs, background gases | Need for filters, dryers, or interference compensation |

| Flow & Sampling Dynamics | Sampling method affects response time and stability | In-situ vs extractive, fast vs slow processes | Impacts installation, lag time, and analyzer design |

| Installation Environment | Environmental stress can reduce analyzer lifespan or cause failure | Outdoor, hazardous area, corrosion-prone zones | IP rating, explosion-proof enclosures, stainless steel construction |

How does the Installation Environment Influence Analyzer Selection?

Even the most advanced gas analyzer can fail prematurely if it’s placed in the wrong environment. The physical location of your analyzer—indoors or outdoors, safe zone or hazardous area—can significantly impact its performance, reliability, and maintenance needs. That’s why installation conditions must be evaluated just as seriously as process conditions.

1. Indoor vs. Outdoor Installation

Problem: Many analyzers are designed for climate-controlled labs, but industrial installations are often exposed to extreme weather.

Aggravation: Rain, sunlight, humidity, and freezing temperatures can corrode housings, fog optics, or affect sensor calibration.

Solution: For outdoor installations, ensure the analyzer has an appropriate enclosure rating (typically IP65 or higher) and protection features like heaters, sunshields, or ventilation.

Tip: ESEGAS analyzers offer weather-resistant cabinets with integrated HVAC and purge systems for long-term outdoor performance.

2. Hazardous or Explosive Areas (ATEX/IECEx Zones)

Problem: Flammable gases or vapors present explosion risks, requiring special precautions.

Aggravation: Using standard analyzers in Zone 1 or Zone 2 areas can violate safety codes and endanger personnel.

Solution: Choose analyzers with certified explosion-proof (Ex d) or intrinsically safe (Ex i) designs per ATEX/IECEx guidelines. They must also comply with local regulations (e.g., NEC, CNEx).

Note: ESEGAS provides Ex-certified solutions with appropriate cable glands, flame arrestors, and sealed housings.

3. Vibration and Mechanical Stress

Problem: Installations on compressors, turbines, or rotating equipment expose analyzers to constant vibration.

Aggravation: Vibration can loosen connections, misalign optical paths, or damage circuit boards over time.

Solution: Use ruggedized mechanical designs, vibration-dampening mounts, and fiber-optic or remote sampling heads to isolate the analyzer from mechanical stress.

4. Corrosive or Dusty Environments

Problem: Many industrial areas—like fertilizer plants, steel mills, or wastewater treatment—contain corrosive gases (e.g., HCl, NH₃) or heavy particulates.

Aggravation: These elements degrade analyzer optics, corrode sensors, or clog sampling lines.

Solution: Use analyzers with corrosion-resistant materials (e.g., 316L stainless steel, PTFE), air purging systems, or inline filters. Consider non-contact (in-situ) methods when possible.

5. Electrical Noise and Signal Interference

Problem: High-voltage equipment, variable frequency drives (VFDs), and power switching systems generate EMI/RFI noise.

Aggravation: This can disrupt analog/digital signals, cause false alarms, or even damage sensitive components.

Solution: Choose analyzers with shielded enclosures, proper grounding, and optical or isolated communication protocols (e.g., fiber optics, Modbus over RS485 with isolation).

What are the Features of ESEGAS Process Gas Analyzer Products?

Our company can provide different types of process gas analyzers, including

☑ Online Process Gas Analyzers

☑ Portable Process Gas Analyzers

☑ Extraction Process Gas Analysis Systems

☑ TDL Process Gas Analyzers

Different installation methods and different kinds of measurement technology to meet the needs of the site

Highlights of ESEGAS analyzers include customizable sensor configurations, explosion-proof housings, real-time data transmission, and integration into control systems like DCS or PLC. The company’s commitment to long-term support, calibration services, and remote diagnostics makes their analyzers a preferred choice in demanding industries.

Conclusion

Selecting a process gas analyzer is not about choosing a device—it’s about designing a solution. From gas chemistry and plant conditions to vendor support, your decision defines process safety and efficiency. Trust partners like ESEGAS to deliver solutions that perform.