Even the most advanced Explosion-Proof Gas Analyzer can fail if poorly maintained—putting safety, compliance, and operational uptime at serious risk.

Daily maintenance of an Explosion-Proof Gas Analyzer ensures safety, accuracy, and equipment longevity in hazardous environments. This process includes inspection, cleaning, calibration verification, and proper documentation—each aligned with safety regulations and operational best practices.

Routine checks might seem repetitive, but they are the front line of defense against costly breakdowns and dangerous incidents. Keep reading to uncover the essential maintenance actions you should never skip.

Why Does an Explosion-Proof Gas Analyzer Require Routine Maintenance?

Neglecting maintenance can compromise safety and violate compliance.

Explosion-Proof Gas Analyzers are designed for continuous operation in volatile environments such as oil refineries, petrochemical facilities, LNG terminals, and confined industrial spaces where flammable gases and vapors may be present. These analyzers are often exposed to heat, humidity, dust, corrosive gases, and mechanical vibrations—all of which can lead to gradual deterioration of components like gas sensors, filters, and flameproof enclosures.

Daily maintenance helps detect early signs of failure—like signal drift, delayed response times, or sensor poisoning—that could otherwise lead to incorrect gas concentration readings. A faulty reading from a gas analyzer can delay critical responses in case of gas leaks or combustible atmospheres, creating major safety hazards. Regular upkeep also ensures compliance with ATEX, IECEx, or other hazardous area certification requirements, which mandate ongoing verification of explosion-proof integrity.

What Daily Checks Are Recommended for Explosion-Proof Gas Analyzers?

Proactive inspection helps catch issues before they become failures.

Operators should begin each shift with a structured inspection checklist tailored to the specific Explosion-Proof Gas Analyzer in use. Key daily tasks include:

- Visual inspection of housing: Ensure no cracks, corrosion, or signs of tampering exist on the analyzer’s body, junction box, or cable glands.

- Seal and label check: Confirm that flameproof joints and enclosures are tightly sealed and that certification markings are visible and legible.

- Cable and conduit integrity: Check for loose wiring, exposed copper, or damaged sheathing that may compromise explosion-proof protection.

- Power and communication verification: Ensure the analyzer powers on properly and that signal output (analog or digital) is being received accurately by the control system or DCS.

- Sensor response test: If supported, perform a bump test to confirm sensor responsiveness to a known concentration of target gas.

- Condensation or clogging: Inspect sample lines, filters, or air intakes for condensation buildup, dust, or process contamination.

Each of these checks plays a role in ensuring the analyzer continues to function safely and accurately under hazardous conditions.

What Cleaning Methods Are Safe for Explosion-Proof Equipment?

Using incorrect cleaning tools can damage the device—or trigger ignition.

Cleaning procedures must strictly follow the manufacturer’s safety guidelines, especially for devices installed in Zone 1 or Zone 2 areas. Operators should only clean the exterior of the Explosion-Proof Gas Analyzer unless the unit has been declassified and electrically isolated.

Safe practices include:

- Using anti-static cloths made of lint-free, non-conductive materials to wipe the exterior.

- Avoiding open-flame or abrasive tools which could compromise the explosion-proof rating or scratch the enclosure.

- Never using alcohol or aggressive solvents unless specifically approved in the analyzer’s user manual.

- Inspecting ventilation and drainage points to ensure no dust or residue buildup interferes with thermal dissipation or ingress protection.

If internal cleaning is required—such as for optical sensors or gas sampling components—this must only be done in a safe zone or under gas-free conditions verified by certified personnel.

What Are Common Mistakes in Maintaining Gas Analyzers?

Even well-meaning maintenance can introduce risks if not done correctly.

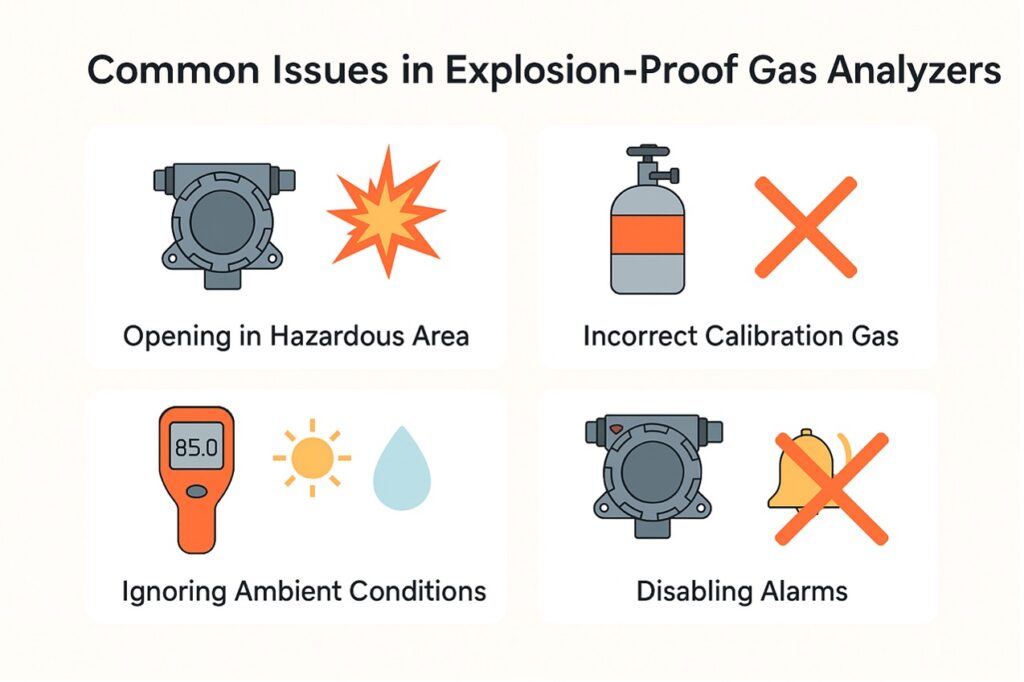

Technicians often make avoidable errors that reduce both the lifespan and reliability of an Explosion-Proof Gas Analyzer. These include:

- Opening the flameproof housing in a hazardous area without proper gas detection and work permits, which violates safety codes and may expose ignition sources.

- Using incorrect or expired calibration gas, which results in faulty sensor adjustment and potentially dangerous false negatives.

- Neglecting ambient condition monitoring—such as humidity or ambient pressure changes—that can impact gas diffusion rates or sensor membrane behavior.

- Disabling alarms or fault codes temporarily to avoid nuisance alerts without addressing the underlying issue.

- Failing to update firmware or software, leading to outdated communication protocols or missed security patches in networked analyzer systems.

All of these practices increase the risk of gas detection failure and violate safety standards like IEC 60079-17 for maintenance of electrical equipment in explosive atmospheres.

How Should Maintenance Activities Be Logged and Tracked?

Documentation is both a safety practice and a compliance requirement.

Proper recordkeeping is essential for traceability, auditing, and root-cause analysis in the event of an incident. Maintenance logs for Explosion-Proof Gas Analyzers should include:

- Date and time of inspection

- Name and ID of the technician

- Detailed findings and measurements (e.g., sensor readings, drift percentage)

- Corrective actions taken (e.g., calibration, filter replacement, firmware update)

- Verification sign-off by a supervisor

Where possible, use a computerized maintenance management system (CMMS) or an instrument asset management (IAM) platform that supports automatic alerts, audit trails, and analytics. Such systems help streamline preventive maintenance schedules and reduce human error.

What Role Does Calibration Play in Daily Maintenance?

Without calibration checks, accuracy is only assumed—not assured.

Calibration ensures that the Explosion-Proof Gas Analyzer provides accurate and traceable gas concentration measurements. While full calibrations are typically scheduled weekly or monthly, a daily bump test (or function check) is essential for verifying that the sensor responds correctly to a known gas.

During a bump test:

- A small amount of calibration gas is applied to the sensor.

- The sensor must respond within a specified range and time.

- No manual adjustment is made unless the reading falls outside tolerance.

If the response fails, the analyzer should be flagged for full calibration or sensor replacement. Daily bump tests are especially critical for applications where toxic or combustible gas presence could lead to immediate evacuation or shutdown procedures.

| Maintenance Task | Recommended Frequency | Notes |

| Visual inspection of housing and seals | Daily | Check for cracks, corrosion, and loose parts. Must not open housing in hazardous areas. |

| Power and signal verification | Daily | Confirm power-on status and output signal (analog/digital). |

| Sensor response bump test | Daily or Before Use | Use certified test gas to confirm sensor response. No adjustment made. |

| Cable and conduit integrity check | Weekly | Inspect cable glands and conduits for damage, corrosion, or moisture. |

| External cleaning | Weekly | Wipe with anti-static cloth; no solvents unless manufacturer-approved. |

| Internal cleaning (if required) | Monthly / As needed | Only in safe zone or under gas-free permit. |

| Calibration with certified gas | Monthly / As per SOP | Full zero/span calibration; record results in maintenance log. |

| Filter/membrane inspection or replacement | Monthly / As needed | Depends on ambient dust or contamination level. |

| Alarm and fault code testing | Monthly | Simulate alarm conditions to ensure proper system response. |

| Firmware/software update check | Quarterly | Update only in safe area and with OEM guidelines. |

| Explosion-proof label and certificate check | Quarterly | Ensure marking visibility and certification validity. |

| Maintenance log review and sign-off | Monthly | Ensure traceability and readiness for audits. |

Conclusion

Daily maintenance of an Explosion-Proof Gas Analyzer is a mission-critical activity that preserves life, property, and productivity in hazardous environments. By following structured inspection, safe cleaning practices, accurate calibration checks, and diligent logging, teams can ensure reliable gas detection and long-term analyzer performance.

if you have any questions, please contact us directly!