(TDLAS Gas Analyzer in Industry)

TDLAS Gas Analyzer stands for Tunable Diode Laser Absorption Spectroscopy. It drives process control, environmental monitoring, and safety improvements. This technique uses a precise diode laser to detect gas concentrations. Industries value TDLAS for its speed and accuracy. It plays a key role in reducing hazards and optimizing operations.

TDLAS gas analyzer measures gas concentration by emitting a narrow‑linewidth diode laser tuned to a target molecule’s absorption line. The beam traverses the sample via a multi‑pass cell or open path, and then a photodiode records the attenuation. ESEGAS new design TDLAS gas analyzer ESE-LASER-U50 ensures stable, reliable data. Consequently, industries like power generation, chemical processing, and environmental monitoring gain accurate, continuous gas insights for control and safety.

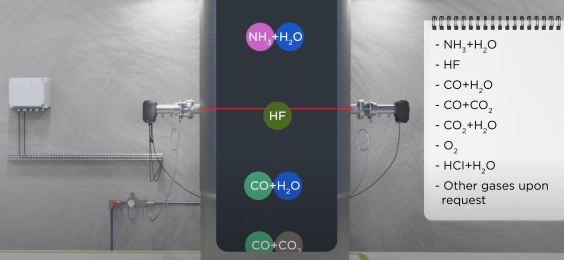

Curious how TDLAS gas analyzer work? In this post, we’ll break down core principles and workflow using the ESE-LASER-U50 as our guide. This TDLAS gas analyzer tracks CO, CO₂, CH₄, NH₃, HF, and HCl. It detects concentration shifts down to parts-per-million (ppm), parts-per-billion (ppb), and even parts-per-trillion (ppt) levels. You’ll learn how TDLAS gas analyzer deliver real-time, high-precision gas readings.

What Are the Key Principles and Components of TDLAS Gas Analyzer?

1. Fundamental Principles of TDLAS

–Beer–Lambert Law and Laser Absorption

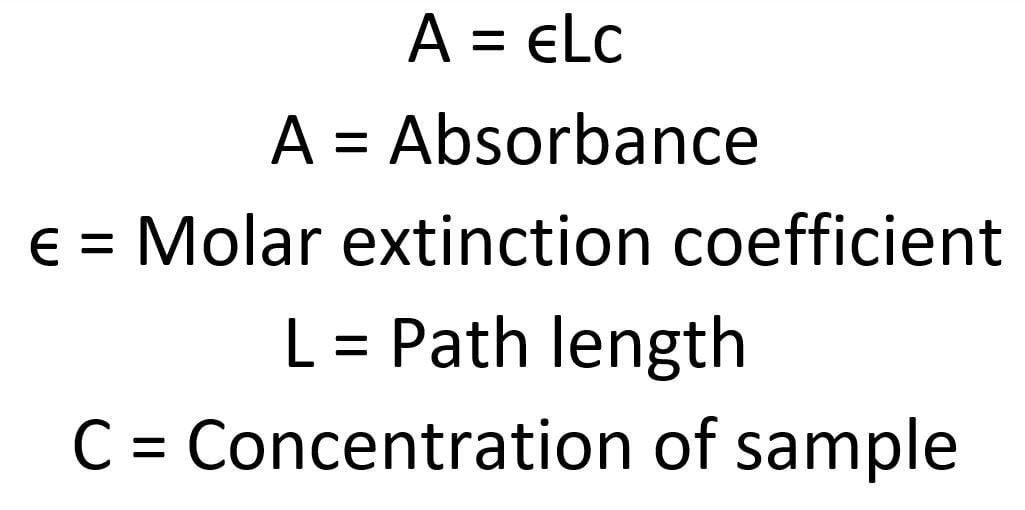

(Beer–Lambert Law)

TDLAS leverages the Beer–Lambert law, which links light attenuation to gas concentration. A tunable diode laser sweeps across an absorption line and measures transmitted intensity. The concentration derives from the absorbance and path length through the gas.

–Selection of Molecular Absorption Lines

Choosing the right rotational–vibrational line boosts selectivity. Multi-line scanning further reduces interference from water vapor, dust, and background gases. This approach maximizes signal quality and minimizes cross-sensitivity.

–Advantages of Diode Lasers

TDLAS gas analyzer uses a tunable diode laser to scan across absorption lines. The laser sweeps its wavelength over a range that covers specific gas signatures. This process targets the exact frequencies that a gas absorbs. Diode lasers such as distributed feedback laser (DFB) and vertical-cavity surface-emitting laser (VCSEL) offer narrow-linewidths and rapid tuning. They maintain single-mode output over a few nanometers. Their compact size and temperature tuning deliver stable, high-precision operation.

2. Core Elements of a TDLAS Gas Analyzer ESE-LASER-U50

The ESE-LASER-U50 comprises three critical hardware modules:

- Laser Source

- DFB or VCSEL diodes with integrated Bragg gratings

- Mode-hop-free tuning over several nanometers

- Temperature and current stabilization for wavelength precision

- Optical Path & Gas Cell

- Heliott multi-pass cell delivering 3–30 m path length

- Compact, thermally stable design minimizes purge volume

- Open-path options for in-situ measurements

- Detector & Signal Electronics

- InGaAs or PbSe photodiodes with low-noise amplifiers

- Digital lock-in amplifier for second-harmonic detection

- High rejection of low-frequency noise and drift

3. System-Level Integration (TDLAS System)

Integrating a TDLAS system extends beyond optics. It involves calibration, data processing, and plant interfaces. Calibrate your TDLAS system regularly to maintain accuracy. Follow strict maintenance schedules for consistent performance. Integrate the system with existing setups carefully. Assess compatibility and retrofit options during upgrades. These practices help you achieve optimal, reliable, and cost-effective performance.

- Real Industrial Case Study

A power plant needed to enhance its existing CEMS with HCl monitoring. ESEGAS answered by installing a TDLAS system to track HCl emissions from waste incineration. The team faced challenges like high background interference and fluctuating gas flow. ESEGAS engineers tuned laser modulation and optimized sensor alignment. As a result, the system delivered precise readings and improved plant safety. The outcome exceeded expectations and set a new standard for process control in power generation.

ESEGAS recently launched the ESE-LASER-200, a new TDLAS NH3/HCL/HF monitoring system. This product features new exterior, advanced laser stability, and improved modulation techniques. It delivers real-time, accurate data for a range of applications. The design enhances ease-of-use and integration with existing systems. Key benefits include enhanced sensitivity and robust performance. Visit https://esegas.com/product/tdlas-gas-analysis-system/ for more details. This innovation marks a significant step forward in industrial gas monitoring.

How Do You Start Up, Operate, and Maintain a TDLAS Gas Analyzer?

- First, pick a straight section for your sampling point. Avoid elbows and sudden diameter changes. Next, weld the probe flange with a 0–5° upward tilt to keep condensate out

- Then, power on and let the ESE-LASER-U50 warm up for 60 minutes. During this period, the internal heater raises the cell and optics to a stable temperature. Meanwhile, the system runs an auto-purge to clear residual gas. Finally, perform a zero/span check using onboard reference cells to set your baseline and full-scale points

- Once commissioned, the ESE-LASER-U50 scans target lines using multi-line wavelength modulation spectroscopy (WMS) across a 3–30 m path length. A digital lock–in amplifier extracts the second-harmonic signal for superb noise rejection

- The 7-inch LCD shows real-time concentration trends, while 4–20 mA, RS-232/485, and relay outputs feed your distributed control system (DCS) or supervisory control and data acquisition (SCADA). Moreover, built-in auto-purging and auto-calibration routines kick in at set intervals, keeping drift under 1 % FS. You’ll see fresh readings every few seconds, ensuring rapid detection of process changes.

3.Maintenance & Troubleshooting

- Keep the sintered-steel filter cartridge clean. Its tool-free design lets you swap cartridges in minutes

- Also, inspect the jet pump’s compressed air lines—its mechanical free design runs at 8 L/min for years without failure

- Next, verify the heating box holds 160 °C to prevent condensation. If readings drift, run a quick auto span check or purge the cell. Finally, watch for optical window fouling—clean with lint free wipes and isopropanol. With these steps, your TDLAS system stays accurate and reliable.

What Are the Practical Applications of a TDLAS Gas Analyzer?

(Waste-Energy Plant)

1.TDLAS drives real-time monitoring in industrial plants, for instance the coal-fired power plants, waste incineration power plants, and chemical plants. It helps control processes by providing immediate gas readings. Engineers rely on it to optimize production and cut waste.

2.TDLAS also tracks atmospheric pollutants, such as greenhouse gas and air quality monitoring. It gives environmental teams clear insights into air quality. 3.TDLAS acts as an early warning system in hazardous areas. It detects leaks swiftly and improves safety. For example, TDLAS measures Hydrogen (H2) concentration in chemical plants to ensure that gas mixture remains within safe concentration limits.

In short, TDLAS gas analyzers play a vital role across industry, environmental care, and safety management.

How to Optimize TDLAS Gas Analyzer Performance and Reliability?

1.Maximizing Sensitivity & Selectivity

To squeeze out the lowest detection limits, focus on optical path length, laser tuning, and signal processing. First, extend the beam path with a Heliott multi-pass cell (3–30 m) to boost absorbance and push resolution down to 0.1 ppm. Next, use multi-line scanning across adjacent absorption lines. This tactic sharpens selectivity by averaging out spectral noise. Finally, lean on a fully digital lock-in amplifier and second-harmonic detection to reject low-frequency noise and pull tiny peaks out of the background .

Key tactics:

- Long Path Cells: 3–30 m optical length for strong absorbance

- Multi–Line Scanning: Reduces cross-sensitivity from water vapor and dust

- Harmonic Detection: Digital lock-in amplifier for high SNR

2. Mitigating Interferences

Real world gas streams throw dust, moisture, and background species at your TDLAS gas analyzer. Thus, heat and filter the sample before it meets the optics. An isothermal sampling probe keeps gas above dew point at 160 °C, preventing condensate. A sintered-steel filter cartridge captures particulates; you swap it tool-free in minutes. Meanwhile, auto-purge routines use compressed air to clear residual dust and maintain a clean cell .

Best practices:

- Heated Probe: 160 °C heating box avoids condensation

- Sintered Filter: 0.2 µm stainless steel cartridge for dust removal

- Auto–Purge: 8 L/min jet pump keeps optics clear

3. Ensuring Reliability in Harsh Environments

When you deploy in hot, dusty, or explosive zones, ruggedize every component. Start with an IP65-rated, 2 mm 316L stainless steel cabinet. Inside, control modules handle auto-sampling, purging, and alarms. The probe’s rain-proof cover and corrosion-resistant steel stand up to outdoor conditions. Plus, the jet pump runs without moving parts, so it won’t seize under heavy dust loads. Together, these features keep your TDLAS system running smoothly for years .

Reliability features:

- IP65 Cabinet: Weather proof, corrosion-resistant 316L stainless steel

- Jet Pump: Mechanical free design for stable, long term sampling

- Automatic Controls: Built-in purge, calibration, and fault alarms

By combining extended path lengths, advanced signal processing, robust sampling hardware, and rugged enclosures, you’ll achieve peak performance and rock solid reliability in any field application.

What Future Trends Define the Future of TDLAS Gas Analyzer?

(AI in gas monitoring)

TDLAS gas analyzer has proven essential in modern industry. It delivers fast, accurate gas detection for process control, environmental monitoring, and leak detection. Its high sensitivity and selectivity help engineers optimize operations and enhance safety. TDLAS systems offer non-intrusive, real-time measurements that reduce downtime and improve efficiency. They convert complex optical signals into actionable data, allowing for precise adjustments. In short, TDLAS gas analyzer transforms industrial practices by providing reliable and robust gas analysis.

Looking ahead, TDLAS gas analyzer continues to evolve. Emerging trends point to smaller, more integrated systems. Enhanced laser technologies and smarter modulation methods promise to boost performance further. Future designs may include wireless connectivity and AI-driven data interpretation. These improvements will broaden TDLAS applications in smart cities and autonomous monitoring. Ultimately, the bright future of TDLAS gas analyzer inspires new possibilities and deeper industrial insights.