Uncontrolled gas emissions in lithium battery production can lead to safety risks and reduced efficiency. Online gas analyzers provide the real-time insight manufacturers need to avoid disaster and optimize performance.

Online gas analyzers play a critical role in lithium battery manufacturing by continuously monitoring volatile compounds and hazardous gases. Their application ensures process stability, product consistency, and workplace safety across multiple production stages.

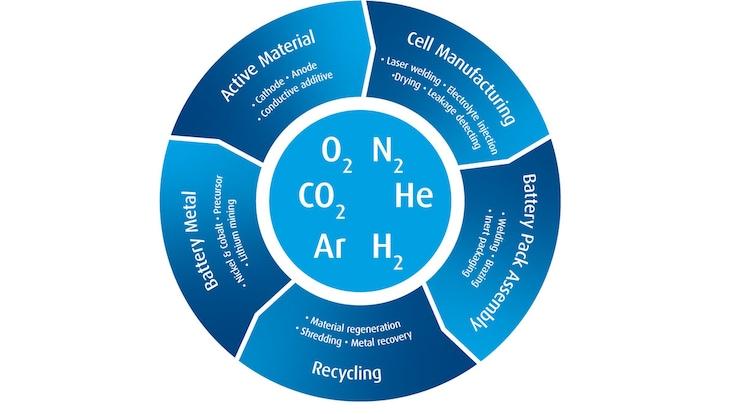

While knowing the benefits of gas analyzers is useful, understanding how they contribute at each manufacturing stage reveals their true value. Let’s explore their specific applications in lithium battery production.

What Gas Monitoring Challenges Exist in Lithium Battery Manufacturing?

Problem: Lithium battery production is a chemically intensive process, where the release of hazardous or reactive gases poses major risks to product quality, safety, and compliance.

Lithium-ion battery manufacturing involves multiple stages that produce or interact with gaseous substances, each bringing specific monitoring challenges. In the slurry mixing and coating phase, N-Methyl-2-pyrrolidone (NMP), a volatile organic solvent, evaporates and accumulates in the air. Inadequate control of its concentration can hinder drying efficiency, result in environmental violations, or even ignite under certain conditions.

Similarly, ensure battery stability. Excess moisture is another critical issue, particularly in cell assembly and electrolyte filling stages. Water can react with lithium salts like LiPF₆, forming hydrofluoric acid (HF)—a corrosive and toxic compound that deteriorates battery materials and poses safety risks to workers.

Furthermore, hydrogen and carbon monoxide may evolve during the formation and aging stages, especially when cells are being charged for the first time. Accumulated flammable gases, if left undetected in enclosed spaces, can create explosion risks. These gases also indicate internal abnormalities that can result in defective cells.

Each of these gases varies in terms of reactivity, detection difficulty, and response time needed. This means manufacturers must employ highly sensitive, selective, and real-time gas detection systems. However, selecting and integrating such systems across a complex, fast-moving production environment is not straightforward—it requires a deep understanding of chemical behavior, equipment compatibility, and regulatory limits.

Without online gas analysis, manufacturers rely on periodic manual checks or indirect indicators, which are often too slow or imprecise to prevent contamination, equipment damage, or quality issues. Real-time, inline gas monitoring is thus not just a luxury—it’s a necessity to keep production safe, efficient, and compliant with global standards.

How Do Online Gas Analyzers Improve Stability During Electrode Preparation?

In lithium battery production, electrode preparation involves mixing active materials with binders and solvents—commonly N-Methyl-2-pyrrolidone (NMP)—and then coating the slurry onto aluminum or copper foil. The coated electrodes are then dried in large ovens to evaporate the solvent, a step that is both energy-intensive and chemically sensitive.

1. Optimizing Drying Efficiency and Coating Quality

Online gas analyzers monitor the concentration of NMP vapors in the drying oven’s exhaust in real time. By doing so, they help control the drying temperature and airflow rate precisely.

- Too little solvent removal results in residual NMP in the electrode, affecting battery performance and long-term safety.

- Over-drying can degrade binder distribution or cause cracking on the electrode surface.

With real-time data, drying ovens can automatically adjust parameters to maintain optimal solvent removal, reducing energy consumption and ensuring uniform coatings.

2. Reducing Material Waste and Production Variability

Inconsistent gas conditions can lead to batches with non-uniform coatings, resulting in electrodes that must be scrapped or reprocessed. This not only wastes costly raw materials (like lithium-based cathode powders and NMP) but also slows production throughput.

By maintaining tight environmental control, online analyzers ensure that every electrode layer meets predefined thickness and solvent residue targets. This leads to:

- Higher first-pass yield

- Fewer rejected batches

- Improved repeatability across production runs

3. Enhancing Solvent Recovery and Environmental Compliance

NMP is a hazardous air pollutant and is subject to strict emission limits in many regions. Online gas analyzers allow manufacturers to:

- Monitor solvent emissions in exhaust streams

- Optimize recovery system loading, such as condensation or adsorption units

- Document emission trends for regulatory reporting

This ensures that facilities remain compliant with environmental regulations while maximizing solvent reuse—an economic and ecological benefit.

4. Supporting Predictive Maintenance

Fluctuations in gas composition may indicate developing issues with the drying system, such as:

- Exhaust fan underperformance

- Filter blockages

- Temperature control faults

With continuous gas data, maintenance teams can identify anomalies early and address them before they escalate into production downtime or product defects.

How Do Gas Analyzers Enhance Environmental and Worker Safety?

Invisible, odorless gases such as hydrogen, carbon monoxide, or hydrofluoric acid can accumulate in lithium battery plants—without proper monitoring, they pose a silent threat to workers and the surrounding environment.

The nature of lithium battery manufacturing makes it a chemically sensitive process. High temperatures, volatile solvents, and electrochemical reactions all contribute to the potential release of harmful gases. In such an environment, traditional ventilation or periodic manual checks are no longer sufficient. Online gas analyzers fill this critical safety gap by continuously and automatically monitoring the ambient and process-related gas composition throughout the facility.

For example, during electrode drying and electrolyte filling, toxic or flammable gases such as NMP, hydrogen (H₂), or carbon monoxide (CO) may leak from enclosed systems. In the formation stage, when batteries are first charged, they may emit gases under pressure—some of which could indicate internal defects or even pre-runaway conditions. Online gas analyzers detect these emissions in real time and can trigger automated alarms or system shutdowns before gas concentrations reach hazardous levels.

Beyond immediate threat detection, gas analyzers also support long-term environmental safety. Emissions such as VOCs are tightly regulated in most regions. Real-time data provided by analyzers enables facilities to stay within legal emission thresholds, avoid fines, and report compliance to regulatory bodies. Moreover, analyzers integrated into exhaust and air purification systems can optimize the activation of scrubbers or solvent recovery units, reducing energy waste while maintaining a safe air standard.

In worker-dense zones such as assembly or inspection lines, fixed-point analyzers equipped with electrochemical sensors provide early detection of toxic gas leaks. This not only protects human health but also supports occupational safety audits and certifications. In emergencies, analyzers also serve as a key component of evacuation protocols by pinpointing gas presence and concentration in specific zones.

In essence, online gas analyzers transform reactive safety measures into proactive risk management strategies. They help manufacturers maintain a clean, compliant, and safe production environment, protecting both people and the planet.

Which Gas Analysis Technologies Are Most Suitable for Lithium Battery Production?

Lithium battery factories operate in complex, chemically active environments where not all gas analyzers are equally effective—choosing the wrong technology can result in inaccurate readings, maintenance issues, or safety blind spots.

Selecting the right gas analysis technology is not a one-size-fits-all decision. Different stages of lithium battery production generate different types of gases, each requiring specific detection capabilities. Sensitivity, selectivity, speed, and environmental tolerance are all critical factors that influence technology selection.

Below are the four most common online gas analysis technologies used in lithium battery manufacturing, along with their suitability for various monitoring needs:

1. Tunable Diode Laser Absorption Spectroscopy (TDLAS)

TDLAS is ideal for detecting low concentrations of gases like moisture (H₂O) and hydrogen (H₂) in high-temperature or low-pressure environments. It provides fast response times and excellent specificity, which makes it especially useful in cell drying and formation processes.

2. Non-Dispersive Infrared (NDIR)

NDIR is widely used for monitoring volatile organic compounds (VOCs) like NMP, as well as CO₂ and CO. It’s robust, cost-effective, and well-suited for continuous emission monitoring in electrode drying ovens and exhaust streams.

3. Electrochemical Sensors

These sensors are suitable for detecting toxic gases such as CO or HF (hydrofluoric acid) in workplace environments. While affordable and simple to integrate, they may require frequent calibration and have a shorter lifespan.

4. Mass Spectrometry (MS)

MS provides comprehensive gas composition analysis with extremely high sensitivity. It’s often used in R&D labs or for quality assurance at the end of production lines. However, the system is expensive, requires skilled operation, and is sensitive to harsh conditions.

Comparison Table of Gas Analysis Technologies for Lithium Battery Manufacturing

| Technology | Target Gases | Sensitivity | Response Time | Environmental Tolerance | Maintenance Need | Typical Application Areas |

| TDLAS | H₂O, H₂ | Very High | <1 second | Excellent (high-temp, corrosive) | Low | Cell drying, formation, gas leakage detection |

| NDIR | NMP, CO₂, CO | Moderate to High | Few seconds | Good (stable environments) | Low to Moderate | Drying ovens, emission control, solvent recovery |

| Electrochemical | CO, HF, NOx, SO₂ | Moderate | Moderate | Fair (limited by humidity/temp) | High | Workplace safety, leak monitoring |

| Mass Spectrometry | Wide range (trace gases) | Extremely High | Seconds to minutes | Poor (requires controlled lab environment) | Very High | Lab analysis, QA, R&D |

ESE’s Battery Production Gas Monitoring Program

Generic gas monitoring solutions often fail to meet the precision, durability, and customization requirements of lithium battery manufacturing—ESE bridges this gap with application-specific, end-to-end solutions.

Recognizing the unique challenges faced by lithium battery producers, ESE has developed a dedicated Battery Production Gas Monitoring Program, integrating its cutting-edge analyzers with process-specific engineering expertise. The program is designed not just to measure gas concentrations, but to optimize the entire monitoring ecosystem—from sensor selection to data integration.

At the core of ESE’s solution is a modular platform built around high-performance technologies such as TDLAS for real-time moisture and hydrogen monitoring, NDIR for VOCs like NMP, and robust electrochemical detectors for workplace safety. These analyzers are calibrated for battery-specific environments: high solvent load, narrow humidity windows, and frequent temperature fluctuations.

ESE also provides system integration services, helping manufacturers embed gas analyzers into existing drying ovens, exhaust systems, and cleanroom controls. Through centralized monitoring dashboards, engineers gain instant visibility into gas trends across multiple production lines, enabling faster responses and long-term process optimization.

In addition, the program includes compliance consulting and after-sales support, ensuring that emission data meets regional environmental regulations such as EU REACH, U.S. EPA standards, and China’s GB codes. ESE’s goal is to deliver more than just instruments—it delivers operational assurance, regulatory confidence, and the foundation for smart manufacturing in the battery sector.

With the Battery Production Gas Monitoring Program, ESE helps manufacturers turn gas risks into process intelligence, making battery production cleaner, safer, and more efficient.

Conclusion

Online gas analyzers are indispensable in lithium battery manufacturing. They not only enhance safety and regulatory compliance but also improve efficiency, reduce costs, and ensure product consistency from start to finish.