Carbon capture refers to separating CO₂ emissions from industrial sources or power plants before they enter the atmosphere. It plays a vital role in climate change mitigation, helping slow global warming. Many industries—cement, steel, chemical—emit CO₂ as a byproduct. Carbon capture allows them to reduce those emissions. Additionally, regulatory pressure and global decarbonization targets make carbon capture more than an option—it has become essential for industries that cannot easily shift to carbon-free fuels.

Capturing CO₂ is one thing; ensuring its purity and tracking its concentration is another. Impurities like moisture, oxygen, and trace hydrocarbons can degrade the captured gas, harm downstream equipment, or render the gas unusable. At the same time, inaccurate monitoring can lead to inefficiencies—wasted energy, overuse of solvents or adsorbents, regulatory non-compliance, or even safety issues. Thus, industries must monitor CO₂ continuously during both capture and purification phases. Accuracy and speed are crucial.

Non-Dispersive Infrared (NDIR) gas analyzers offer a robust, scalable, and cost-effective way to monitor CO₂ concentration and purity. They work without consumable chemicals, respond quickly, and maintain accuracy even in harsh environments.

What Kinds of Carbon Capture Workflows Exist, and How Does an Infrared Gas Analyzer Fit into CO₂ Purification?

A. Carbon Capture Workflows / Technology Landscape

Carbon capture comes in several forms. Each type generates CO₂ under different pressures, concentrations, and impurity burdens. Understanding them helps us see where monitoring matters most.

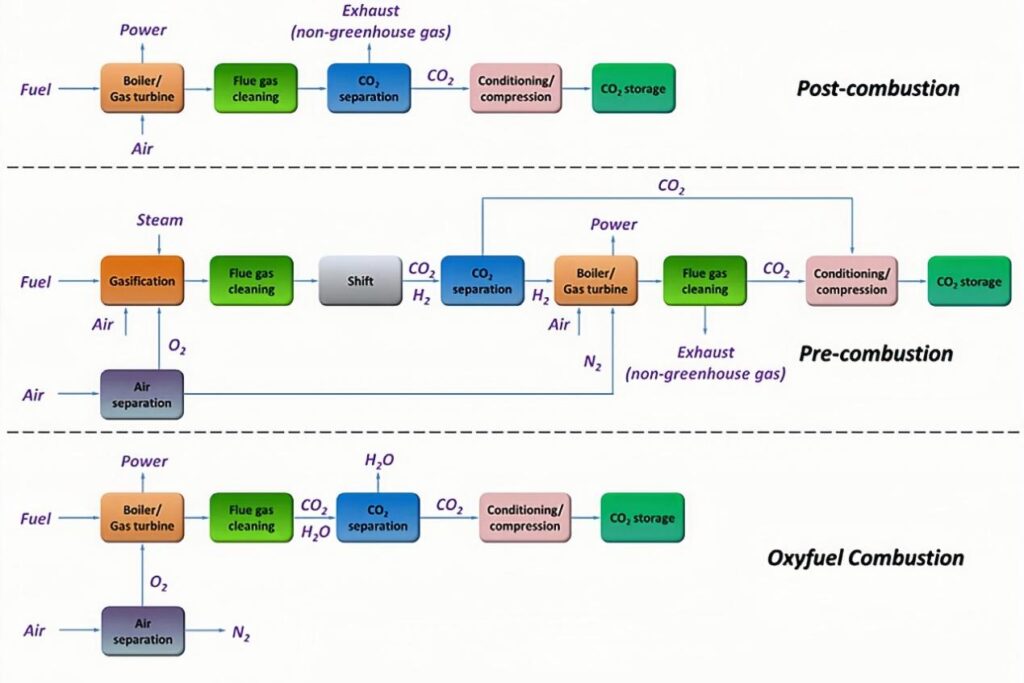

- Post-combustion capture

Fuel burns with air and produces flue gas rich in nitrogen plus CO₂. Plants then separate CO₂ from that mix. Because CO₂ is diluted and at low pressure, the separation and purification stages become demanding. - Pre-combustion capture

Fuel undergoes gasification or reforming. The resulting syngas (CO + H₂) passes through a water-gas-shift reaction to raise CO₂ concentration. This higher partial pressure makes CO₂ easier to separate. - Oxy-fuel combustion

Plants burn fuel with nearly pure oxygen instead of air. Exhaust gas is mostly CO₂ plus water vapor. After condensing the water, what remains is a highly concentrated CO₂ stream. This simplifies purification. - Direct air capture (DAC)

This method pulls CO₂ directly from ambient air. Because CO₂ is very dilute (~400 ppm), the energy input and purification needs are much higher. However, DAC offers negative emissions, which are vital for net zero goals.

After capture, most workflows require purification steps to remove:

- SOₓ, NOₓ (acid gases)

- Moisture (H₂O)

- Oxygen (O₂)

- Trace hydrocarbons

- Particulates and ash

Purification ensures CO₂ meets specifications for storage, usage (chemical feedstock, beverage carbonation, etc.), or transport through pipelines. Without proper purification, impurities can corrode equipment, reduce efficiency, or make the CO₂ unusable.

B. Why Precise Monitoring Matters

After capture and during purification, monitoring CO₂ concentration and purity deeply affects safety, cost, and product value. Below I break down key reasons:

- Safety

Impurities like O₂ or NOₓ can react in unwanted ways. Moisture can cause corrosion or microbial growth. Unchecked, these pose hazards to equipment and personnel. - Efficiency

If the purifier or solvent system works harder than needed—because impurity levels are higher than assumed—it wastes energy. Accurate monitoring lets engineers fine-tune conditions to minimize solvent usage, heat load, or auxiliary power. - Regulatory / Environmental Compliance

Many jurisdictions require reports of capture rates, emissions, and leak detection. Governments may penalize non-compliance. Reliable data ensures that projects stand up to audits and reduce risk of litigation or fines. - Product Value

High-purity CO₂ fetches better prices and finds more uses. For example, food & beverage grade, mineralization, or synthetic fuel production demand specific impurity thresholds. If CO₂ fails to meet specs, downstream customers might reject it, or additional purification adds cost.

Because purification and workflow challenges create tight demands on measurement, we now turn to how the NDIR infrared gas analyzer works under the hood and why it stands out in carbon capture contexts.

What Makes Infrared Gas Analyzer Advantageous for Carbon Capture?

A. Technical Fundamentals of NDIR

An NDIR gas analyzer detects gases by exploiting how molecules absorb infrared light. CO₂, for example, absorbs strongly at about 4.26 µm. Instruments use filters to isolate that specific wavelength. When IR light passes through a gas sample, CO₂ absorbs part of it; the drop in light intensity tells you how much CO₂ exists.

Key components include:

- IR Source: Lamps, mid-infrared LEDs, or MEMS emitters. LEDs or MEMS sources often offer low power and fast response.

- Sample Chamber / Optical Path: A “light tube” or reflective chamber that gives IR light enough distance to interact with gas molecules. Longer path improves sensitivity.

- Filters & Detectors: Bandpass filters select the CO₂ absorption band (often ~4.26 µm); detectors like photodiodes, thermopiles or photovoltaic/quantum detectors sense transmitted light.

- Reference Channel(s): Many designs include a non-absorbing wavelength (e.g. ~3.9 µm) as a reference. Comparing measurement vs. reference helps correct for drift, source variation, or environmental factors.

Together, these parts let NDIR analyzers deliver accurate, stable measurements of CO₂ under diverse conditions.

B. Advantages of NDIR over Alternative Technologies in Carbon Capture / Purification Contexts

NDIR infrared gas analyzers bring several advantages when applied to carbon capture and CO₂ purification. They shine especially in these areas:

- Selectivity & Specificity

Because each gas has unique IR absorption bands, NDIR filters allow precise CO₂ measurement with low cross-sensitivity (if filter design and calibration are good). - Wide Dynamic Range

NDIR systems can measure very low parts per million (ppm) for impurities and also handle high concentrations when CO₂ is bulk (for instance post-capture streams). This flexibility suits both capture and purification stages. - Rapid Response & Continuity

They offer fast measurement cycles. Real-time feedback helps adjust purge, solvent regeneration or membrane operation. Continuous monitoring avoids surprises. - Maturity & Field Proven

NDIR is a well-understood technology. It sees wide deployment in industry, from biogas plants to power stations. That means reliability, many vendor options, and known failure modes. - Lower Operational Cost

They require fewer consumables. They are less reliant on reagents. Maintenance tends to be predictable. Over time, they often cost less per useful hour of accurate measurement compared to some alternative sensor types.

C. Limitations / Challenges and How They Are Managed

Still, infrared gas analyzers and NDIR technology face real challenges. Good design and operational strategy mitigate them.

- Interference from Water Vapor, Particulates, Temp/Pressure Variations

Moisture absorbs IR; dust blocks optical paths. Temperature or pressure changes shift absorption lines. To manage this, plants use sample conditioning: filters, dryers, or heated chambers. - Optical Path Fouling or Degradation, Drift Over Time

Optical windows or filters may degrade. IR source brightness may decay. Regular cleaning, robust materials, and auto-zero or internal reference channels help keep readings accurate. - Calibration Needs, Reference Gas / Internal Calibration Mechanisms

Periodic calibration against known gas standards ensures accuracy. Reference channels or built-in span/zero calibration are critical. ESEGAS integrates these into many of its analyzer models. - Ensuring Linearity Across Concentration Spectrum

Measuring both trace CO₂ and bulk CO₂ in one device puts stress on linearity. Non-linear absorption (Lambert-Beer law) causes diminishing returns at high concentrations. Designers adjust optical path length, choose appropriate detectors, and sometimes use dual sensors to span ranges.

With a firm grasp of NDIR’s principles and strengths, we can now explore how ESEGAS applies this technology in real carbon capture projects and what that means for performance and purity.

How Does an Infrared Gas Analyzer Integrate into Full Carbon Capture Workflows?

A. Overview of ESEGAS’s Approach / Architecture in Carbon Capture and CO₂ Purification

ESEGAS designs its carbon capture monitoring systems with clarity and adaptability in mind. Their architecture places NDIR infrared gas analyzers at critical nodes of the capture process. They combine rugged hardware, intelligent sample handling, and real-time data feedback. What sets ESEGAS apart is their holistic view: they don’t just supply analyzers; they engineer them to meet capture, purification, and verification needs across multiple steps. As a result, their solution improves consistency, reduces inefficiencies, and supports regulatory transparency.

B. How ESEGAS Uses NDIR Analyzers in the Workflow

ESEGAS integrates NDIR infrared gas analyzers throughout three main stages:

- Placement Points

- Before capture: to measure baseline CO₂ and impurity levels in flue gas or syngas.

- After capture: to verify how much CO₂ the capture unit removed.

- During purification: in scrubbers, membrane separators, or cryogenic/chemical stages to ensure removal of moisture, O₂, CO, CH₄, particulates, etc.

- Feedback Control

ESEGAS uses the real-time CO₂ concentration data to optimize purification operations. For example, they adjust solvent regeneration cycles or membrane pressure based on NDIR readings. This dynamic control cuts energy use and prevents over-treating. - Purity Verification

Beyond bulk CO₂, ESEGAS analyzers measure residual impurities (CO, CH₄, O₂, moisture). They ensure the output meets strict product specs—for example, for industrial gas supply or storage. If impurity thresholds deviate, the system flags it or triggers remedial action

C. System Design Considerations Specific to ESEGAS’s Deployment

To make the solution reliable in real plants, ESEGAS ensures:

- Sensor Selection: They choose analyzers with detection ranges matching expected CO₂ and impurity levels, optical path length tuned for sensitivity, and materials that resist corrosion and thermal stress.

- Sample Conditioning: The sample gas often carries moisture, particulates, or pressure/temperature variations. ESEGAS includes filters, moisture traps, pressure regulation and temperature control to protect optics and ensure measurement stability.

- Data Integration: Their NDIR analyzers feed into plant control systems (PLC/SCADA). They provide continuous data streams, alarm signals, and corrective loops (for example, adjust capture media or shut valves) for operational safety and efficiency.

Having seen how ESEGAS integrates NDIR gas analyzers in practical workflows and achieves real gains, it’s time to draw together what makes NDIR infrared gas analyzers indispensable—and outline clear steps engineers and project leaders can take to succeed with solutions like ESEGAS.

Conclusions

NDIR gas analyzers deliver precision, reliability, and speed needed for successful carbon capture. They monitor CO₂ concentration and impurities with high specificity, enabling efficient purification. They reduce waste, cut energy use, and strengthen safety. Moreover, as CO₂ capture becomes regulated and monetized, accurate measurements grow in value—not optional extras. Integrating NDIR analyzers into key points in the capture + purification chain (pre-capture, post-capture, purification) gives plants the data they need to optimize.

Carbon capture is more than catching CO₂—it’s about measuring, controlling, and using that CO₂ safely and economically. An infrared gas analyzer isn’t just an instrument; it’s the bridge between theory and practice. With companies like ESEGAS pushing integration at every stage, the promise of carbon capture becomes real. For plants and engineers, success lies in not only installing NDIR analyzers—but doing so smartly: with strong conditioning, feedback, calibration, and alignment with regulatory and market needs. That turns promise into practice—and climate goals into measured impact.

FAQs: NDIR gas analyzer for carbon capture

Q1: What is an infrared gas analyzer and how does NDIR technology monitor CO₂ in carbon capture projects?

A:

An infrared gas analyzer uses infrared light to detect gas molecules by their absorption of specific wavelengths. In NDIR systems, an IR light source shines through a gas sample; filters and detectors measure the light drop at wavelengths CO₂ absorbs (e.g. ~4.26 μm). The drop in IR signal is proportional to CO₂ concentration. Because NDIR does not require moving optical elements or chemical reactions, it offers stable, continuous monitoring, which is crucial in carbon capture to track CO₂ levels during capture and purification stages.

Q2: Why is CO₂ monitoring so essential for carbon capture and purification?

A:

Monitoring CO₂ continuously helps in several ways:

- Ensures capture efficiency by showing how much CO₂ the capture unit removes from flue or process gases.

- Verifies product purity, especially if the captured CO₂ is to be used or sold. Impurities (O₂, moisture, CO, etc.) degrade quality or damage downstream systems.

- Maintains process safety, since rising levels of CO₂ or leaks can pose health or operational hazards.

- Supports regulatory and environmental compliance, reporting, and carbon credits or tax incentives that often depend on accurate measurement.

Q3: What are the main challenges for using an infrared gas analyzer in harsh carbon capture environments?

A:

Using NDIR gas analyzers in carbon capture plants poses several challenges:

- Interference from moisture and particulates: Water vapor or dust can scatter or absorb IR light, leading to errors unless the sample is conditioned (dried, filtered).

- Temperature and pressure swings: Fluctuation in ambient or gas sample conditions affect absorption bands and detector response. Instruments with controlled temperature or compensation are needed.

- Optical fouling: Deposits on windows or filters block light, reducing accuracy. Regular cleaning or auto-zeroing helps.

- Calibration drift: Sensors degrade over time. Periodic calibration or reference channels ensure continued accuracy.

ESEGAS addresses these through robust sample pre-conditioning, multi-channel filters, auto calibration, and rugged design in their analyzers.

Q4: How does the ESEGAS solution integrate NDIR gas analyzers into carbon capture systems in real-world projects?

A:

ESEGAS designs systems where NDIR gas analyzers appear at detailed points in the carbon capture and purification chain:

- Pre-capture monitoring of flue gas to measure baseline CO₂ and impurities.

- Post-capture tracking to assess how effectively capture media or solvents remove CO₂.

- Purification verification where captured CO₂ is further cleaned (removing moisture, O₂, CO), preparing for storage or utilization.

Q5: How does IR-based monitoring affect the cost and efficiency of carbon capture and CO₂ purification?

A:

Proper IR monitoring improves efficiency and can reduce operational cost by:

- Reducing solvent or adsorbent waste: Real-time tracking lets plants regenerate or replace media just in time.

- Minimizing energy consumption: Optimized capture and purification steps run more efficiently when driven by accurate gas concentration feedback.

- Avoiding downtime: Early detection of leaks, fouling, or abnormal gas composition prevents shutdowns or maintenance emergencies.

- Enhancing CO₂ product value: Purified CO₂ commands better prices if it’s used for industrial gas, food & beverage, or sequestration.

Though high-accuracy IR analyzers have upfront cost, their lifetime savings and regulatory compliance gains often justify the investment.

Q6: Can an infrared gas analyzer detect multiple gases besides CO₂ in carbon capture operations?

A:

Yes. Many modern NDIR-based gas analyzers can monitor several gases simultaneously. Depending on optical filters and detector channels, these may include:

- CO (carbon monoxide)

- CH₄ (methane)

- H₂O (moisture), either directly or through sample conditioning indicators

- O₂ (sometimes via complementary sensors)

ESEGAS gas analyzers often combine multiple detectors (e.g. CO₂ + CO + CH₄) in one module. Multiple-gas capability helps optimize capture media, detect contaminations, and reduce downstream purification load.