Undetected gas emissions cost more than money—they endanger health and damage reputations. Gas analyzers are the frontline defense for emission control in wastewater treatment facilities.

Gas analyzers in wastewater treatment plants detect hazardous emissions like methane, ammonia, and hydrogen sulfide, helping ensure safety, regulatory compliance, and operational efficiency.

Proper gas detection technology is no longer optional—it’s a critical component of safe, compliant wastewater management. Let’s explore what gases are measured and how analyzers function in these challenging environments.

What Gases Must Be Monitored In Wastewater Treatment Plants?

Invisible gases, visible damage—only detection can protect.

Wastewater treatment processes, especially anaerobic digestion and sludge handling, generate a complex mixture of gases. Among these, four primary gases are considered critical for continuous monitoring due to their impact on safety, compliance, and odor control:

- Methane (CH₄) – Produced during anaerobic decomposition of organic matter, methane is both highly flammable and explosive in confined spaces. It is also a potent greenhouse gas. Accurate monitoring is vital to prevent accumulation and enable safe biogas recovery systems.

- Hydrogen Sulfide (H₂S) – This toxic gas forms when sulfate-reducing bacteria break down sulfur-containing compounds in the absence of oxygen. Even at low concentrations, H₂S can cause respiratory distress, metal corrosion, and strong odor complaints. Its presence also poses a serious health hazard for personnel.

- Ammonia (NH₃) – Commonly emitted from sludge treatment and urea breakdown, ammonia is corrosive and irritating to the eyes and respiratory system. Monitoring NH₃ helps maintain workplace safety and is often required to meet air quality standards.

- Carbon Dioxide (CO₂) – While less toxic, high concentrations of CO₂ can displace oxygen in confined spaces, leading to asphyxiation risks. It is also used as a key indicator in assessing microbial activity and ventilation effectiveness in treatment tanks.

In addition to these, certain facilities may also monitor nitrous oxide (N₂O) due to its climate impact and relevance in advanced nitrogen removal processes. Continuous gas analysis ensures real-time awareness of environmental and occupational hazards, allowing for immediate corrective actions and long-term process optimization.

How Do Gas Analyzers Operate In Wastewater Environments?

Complex gases need smarter technology.

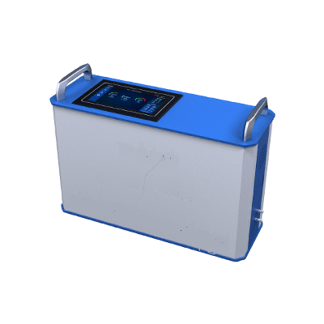

Wastewater treatment environments challenge sensors with high humidity, corrosive chemicals, and airborne particulates. ESEGAS devices are designed specifically for such harsh settings, combining rugged hardware with advanced sensor technologies optimized for wastewater gas monitoring:

- ESEGAS NDIR Methane/CO₂ Analyzers

- ESE-LASER-100 Ammonia (NH₃) Analyzer

- UV-DOAS & Portable FTIR Analyzers

Key Features Across These ESEGAS Instruments:

- Rugged Design: IP-rated enclosures, corrosion-resistant optics, and sample-conditioning modules guard against harsh wastewater conditions.

- Technological Diversity: NDIR for methane/CO₂, electrochemical systems for toxic gas detection, UV-DOAS, TDLAS, and FTIR for multi-gas environments.

- Integration & Maintenance: Built for seamless SCADA/PLC integration, many models include auto-calibration, self-cleaning, and remote diagnostics.

- Portability Options: For field inspections and leak detection, portable FTIR and ESE-LASER-100P units offer flexible deployment alongside fixed station solutions.

Overall, ESEGAS gas analyzers combine measurement accuracy, environmental resilience, and system connectivity—making them ideal for continuous, dependable monitoring in wastewater treatment plants.

What Are The Benefits Of Installing Gas Analyzers In Wastewater Facilities?

Compliance is not enough—optimization is the goal.

Installing gas analyzers in wastewater treatment plants brings far more than just regulatory compliance—it’s a strategic investment in safety, efficiency, and operational intelligence.

1. Enhanced Worker Safety

Hazardous gases like hydrogen sulfide (H₂S), ammonia (NH₃), and methane (CH₄) can accumulate rapidly in confined spaces such as sludge digesters, pumping stations, and manholes. Real-time detection from gas analyzers allows immediate response to leaks or dangerous buildup, significantly reducing the risk of poisoning, explosion, or asphyxiation incidents among personnel.

2. Regulatory Compliance and Reporting

Environmental agencies require strict control of gas emissions and proper documentation. With continuous emissions monitoring systems (CEMS) such as those from ESEGAS, facilities can generate timestamped data logs and compliance reports automatically. This minimizes the risk of fines, shutdowns, or reputational damage.

3. Odor Management and Community Relations

Odor complaints from surrounding communities often originate from uncontrolled emissions of ammonia or volatile organic compounds (VOCs). By pinpointing emission sources, gas analyzers enable targeted odor control measures—like biofilters or chemical scrubbers—helping to maintain a positive public image and avoid municipal penalties.

4. Operational Efficiency and Process Optimization

Real-time gas monitoring helps operators adjust aeration, digestion, and chemical dosing processes. For example, maintaining optimal methane levels in anaerobic digesters can improve biogas yields and reduce sludge volumes. This optimization translates directly into energy savings and lower operating costs.

5. Predictive Maintenance and Asset Protection

Gas analyzers also act as early warning systems. Rising levels of corrosive gases like H₂S may signal pump failure or biofilm accumulation. Early detection helps schedule maintenance before failures occur, protecting equipment and extending the lifespan of critical assets such as blowers, pipes, and scrubbers.

6. Data-Driven Decision Making

Advanced analyzers, especially those integrated into SCADA or remote monitoring platforms, provide actionable insights. Over time, this data enables pattern recognition, leak trend analysis, and informed budgeting for upgrades or process redesigns.

ESEGAS analyzers, with their precise multi-gas detection, auto-calibration features, and real-time data capabilities, help wastewater facilities shift from reactive troubleshooting to proactive, optimized operations.

How To Choose The Right Gas Analyzer For Wastewater Treatment?

Not all analyzers are created equal—choosing wrong can cost you.

Selecting the appropriate gas analyzer for a wastewater treatment facility requires a careful balance of performance, durability, and application-specific functionality. An incorrect choice can lead to inaccurate readings, frequent maintenance, or even safety risks. Here’s how to make an informed decision:

1. Identify Target Gases and Sources

The first step is defining which gases need to be monitored—typically methane (CH₄), hydrogen sulfide (H₂S), ammonia (NH₃), and carbon dioxide (CO₂). Each gas originates from specific zones:

- Digesters: CH₄, CO₂

- Sludge handling: H₂S, NH₃

- Aeration tanks: O₂, N₂O

- Stack emissions: NOₓ, SO₂, VOCs

Choose an analyzer capable of detecting your facility’s full gas profile. For example, ESEGAS UV-DOAS 500P is ideal for multi-component stack emissions, while ESE-LASER-100 excels at precise NH₃ monitoring in sludge processing areas.

2. Select the Appropriate Detection Technology

Different sensors suit different needs:

- NDIR: Stable and low-maintenance for CH₄/CO₂

- Electrochemical: Cost-effective for H₂S/NH₃ in confined areas

- TDLAS: High-precision detection in low-concentration NH₃ zones

- FTIR: Simultaneous multi-gas analysis, great for complex emissions

- UV-DOAS: High-speed response, ideal for stack gas applications

ESEGAS offers all of these technologies in purpose-built systems, allowing precise matching to your technical and budgetary requirements.

3. Evaluate Environmental Suitability

Wastewater facilities expose equipment to humidity, corrosion, and dust. Ensure analyzers have:

- IP65/IP66 enclosures

- Acid- and base-resistant components

- Internal sample conditioning systems (e.g., dehumidifiers, filters)

ESEGAS designs units specifically for harsh environments, including sealed optics, reinforced housings, and integrated dust filters.

4. Decide Between Portable vs. Fixed Systems

- Portable analyzers are ideal for site surveys, leak detection, and maintenance checks.

- Fixed continuous monitoring systems (CEMS) suit permanent installations with remote supervision.

For example, ESE-LASER-100P is a handheld analyzer for mobile NH₃ detection, while UV-DOAS 500Fprovides 24/7 real-time stack emission analysis with remote diagnostics.

5. Integration and Data Management

Look for SCADA or MODBUS compatibility, alarm outputs, cloud storage, and auto-calibration capabilities. ESEGAS instruments are SCADA-ready and offer real-time data transmission, ensuring seamless integration with existing plant infrastructure.

A tailored analyzer selection ensures reliability, compliance, and long-term cost savings. ESEGAS provides technical consultations to help facilities choose the optimal configuration for each monitoring point.

Gas analyzers are indispensable tools for modern wastewater management. They not only protect staff and the environment but also enhance plant performance. Choosing the right system ensures long-term compliance, safety, and cost efficiency.