With the continuous upgrading of environmental protection regulations and people’s increasing attention to environmental issues, the demand for air quality monitoring is also increasing. Ammonia (NH3) is an important atmospheric pollutant, mainly derived from agriculture, industry, transportation and other activities. The NH3 concentration in chimney flue gas not only has an important impact on environmental quality and the health of ecosystems, but may also cause harm to human health. Therefore, it is particularly important to study and monitor the NH3 concentration in chimney flue gas.

Traditional NH3 gas analysis instruments are usually based on chemical methods, but these methods have many problems, such as being time-consuming, complex, requiring large amounts of chemical reagents and hazardous waste disposal. Fortunately, the development of laser technology provides new ways for NH3 gas analysis, improving the accuracy and efficiency of monitoring. This article will introduce the application of NH3 gas analyzer in chimney flue gas, paying special attention to the new prospects of laser technology.

Importance of NH3 Gas

First, let us understand the importance of NH3 gas. Ammonia is a colorless gas that often has a pungent odor. It is mainly produced by fertilization and animal waste emissions from agricultural activities, but can also come from industrial processes and vehicle exhaust.NH3 has many impacts on the atmosphere and environment,include:

1. Formation of acid rain: NH3 reacts with sulfuric acid and nitric acid in the atmosphere to form acidic sediments, which leads to the formation of acid rain and has a negative impact on soil, water bodies and ecosystems.

2. Formation of atmospheric particulate matter: NH3 is the precursor substance of particulate matter (PM2.5 and PM10) in the atmosphere, causing harm to air quality and health.

3. Ecosystem impact: NH3 emissions can cause soil acidification and adversely affect plants and aquatic organisms.

Therefore, monitoring the NH3 concentration in chimney flue gas is crucial to control air pollution, protect the environment and maintain public health.

Limitations of Traditional NH3 Gas Analysis Methods

Traditional NH3 gas analysis methods mainly include chemical absorption, chromatography and spectroscopy. These methods can accurately measure NH3 concentration to a certain extent, but have some obvious limitations:

1. Time-consuming and complex: Chemical absorption methods and chromatography require complex sample preparation and analysis processes, and often take a long time to obtain results.

2. Reagents and waste disposal: These methods require the use of chemical reagents, generate waste, and require regular maintenance and calibration of instruments.

3. Sensitivity limitations: The sensitivity of traditional methods is subject to certain limitations and may not be able to detect low concentrations of NH3.

4. Difficulty in online monitoring: Due to complex operating procedures, traditional methods have difficulties in real-time online monitoring.

| Aspect | Traditional Analyzer | Laser Technology Analyzer |

| technology | Chemical methods, chromatography, spectroscopy, etc. | Laser absorption spectroscopy (TDLAS), laser induced fluorescence (LIF), laser Raman spectroscopy (Raman), etc. |

| principle | Based on chemical reactions, separation, absorption or scattering | Interactions based on excited or scattered laser photons |

| performance | Relatively low measurement accuracy, long analysis time, need for chemical reagents, need for reagent waste disposal | High measurement accuracy, real-time or rapid analysis, no chemical reagents required, reduced waste generation |

| parameter | Limited sensitivity, often requires multi-step sample processing | High sensitivity, can detect gas concentrations as low as ppb level |

| application | Traditional NH3 analysis, environmental monitoring, laboratory research, partial online monitoring | Industrial emission monitoring, agricultural waste treatment, urban air quality monitoring, scientific research projects, etc. |

Due to these limitations, researchers began to look for more rapid, accurate and reliable NH3 gas analysis methods, and laser technology came into being.

Application of laser technology in NH3 gas analysis

Laser technology has made significant progress in the field of gas analysis and has shown potential in NH3 gas analysis. The main advantages of this technology include:

1. High accuracy: Laser technology can provide extremely high measurement accuracy and can detect NH3 concentrations as low as ppb (one hundred million) levels.

2. Real-time monitoring: Laser technology can achieve real-time online monitoring and respond quickly to concentration changes, helping to better understand NH3 emissions.

3. No reagents required: Unlike traditional methods, laser technology does not require the use of chemical reagents, reducing the generation of chemical waste.

4. High selectivity: Laser technology can achieve highly selective measurement of NH3 by selecting the appropriate laser wavelength.

The application of laser technology is usually based on one of the following principles:

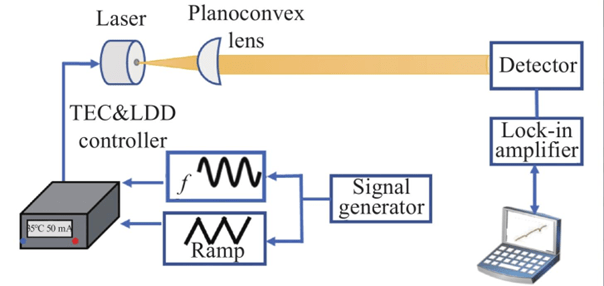

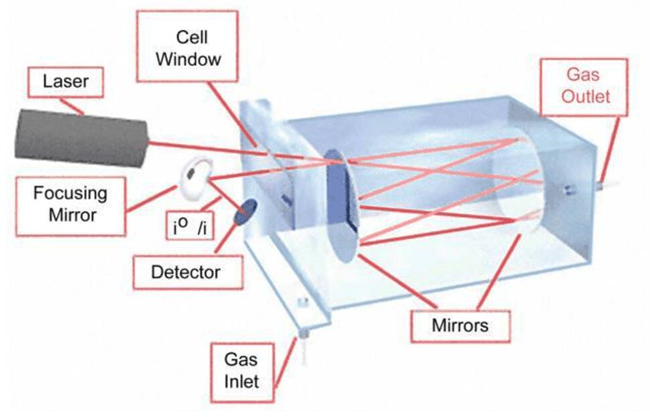

–Laser Absorption Spectroscopy (TDLAS): Determine the NH3 concentration by measuring the absorption of NH3 molecules at specific laser wavelengths.

– Laser-induced fluorescence (LIF): Excite NH3 molecules and measure their fluorescence emission to determine concentration.

–Laser Raman Spectroscopy(Raman): NH3 molecules are identified by scattering spectroscopy and their concentration is measured.

These technologies can be used flexibly in a variety of environments, including industrial chimneys, agricultural sites and urban air quality monitoring stations.

Our NH3 gas analyzer products

Ammonia TDLAS gas analyzers are widely used in industries such as agriculture, environmental monitoring, chemical plants, and food processing, where accurate and reliable measurement of ammonia concentrations is crucial for safety, process control, and compliance with regulations.

Here are some key advantages of using an ammonia TDLAS gas analyzer:

- High Selectivity: TDLAS technology provides high selectivity for the target gas, in this case, ammonia. The analyzer utilizes a laser diode that emits light at a specific wavelength corresponding to the absorption line of ammonia. This allows for accurate and specific measurements of ammonia concentration, even in the presence of other gases.

- Wide Dynamic Range: TDLAS gas analyzers offer a wide dynamic range, enabling measurements across a broad range of ammonia concentrations. They can accurately measure low parts-per-billion (ppb) levels up to high parts-per-million (ppm) concentrations, making them suitable for a variety of applications.

- Fast Response Time: TDLAS gas analyzers provide rapid response times, allowing for real-time monitoring of ammonia levels. The inherent speed of the laser-based measurement technique enables quick detection and measurement of ammonia concentration changes, facilitating prompt action or intervention if needed.

- Non-Intrusive and Remote Sensing: TDLAS gas analyzers are non-intrusive, meaning they do not require direct contact with the gas sample. The laser beam is typically directed through a sampling cell or pipe, allowing for remote sensing of the ammonia gas. This feature is beneficial for continuous monitoring applications or situations where direct access to the gas stream is challenging.

- High Accuracy and Precision: TDLAS gas analyzers offer high accuracy and precision in measuring ammonia concentrations. The narrow linewidth of the laser source and the use of sophisticated spectral analysis algorithms result in precise measurements, ensuring reliable and consistent data.

- Low Maintenance and Long-Term Stability: TDLAS gas analyzers often have minimal moving parts and require little maintenance. They offer long-term stability and robustness, reducing the need for frequent calibration and minimizing downtime.

- Compact and Modular Design: Ammonia TDLAS gas analyzers are available in compact and modular designs, making them suitable for various installation requirements. They can be integrated into existing monitoring systems or deployed as standalone units in different locations.

Technical parameters

| Measured gas | NH3 |

| Method | Tunable Diode Laser Spectrometry (TDLAS) |

| Range | NH3:10ppm/1000ppm/40% |

| Accuracy | ± 1% full scale reading depending on integration stability (temperature & pressure) |

| Precision | 2%FS |

| Displayed resolution | 0.1ppm/0.01% |

| Response time | Less than 15S (at gas flow rate of 3 L/min) |

| Sampling Gas Temperature | ≥180℃ |

| Analog Output | 4`20mA DC, Insulating output, maximum load is 900 ohm, |

| Digital Output | RS232/485 |

| Power Supply | 90-240VAC / 50/60Hz 120W |

| Warm up time | 30 minutes |

| Interface | RS232 |

| Ambient Temperature | Temp:-10-50℃ Humidity:0-90%RH |

Practical Application Cases of NH3 Gas Analyzer

Now, let’s look at some examples of NH3 gas analyzers in practical applications:

1. Industrial emission monitoring: Many industrial facilities emit NH3 gas through chimneys. NH3 gas analyzers using laser technology can help monitor and control these emissions, ensuring plants comply with environmental regulations.

2. Agricultural sector: Agriculture is one of the main emission sources of NH3. In agriculture, NH3 gas analyzers can be used to monitor agricultural waste disposal, fertilizer application and livestock emissions.

3. Air quality monitoring: Air quality monitoring stations in urban and industrial areas use NH3 gas analyzers to monitor NH3 concentration to evaluate air quality and take necessary measures to improve it.

4. Scientific research and environmental protection projects: NH3 gas analyzers are also widely used in scientific research projects, such as atmospheric chemistry research and environmental protection assessment.

Future development and challenges of laser technology in NH3 gas analysis

Although laser technology shows great potential in NH3 gas analysis, there are still some challenges and development opportunities:

1. Cost issue: The cost of laser technology instruments is relatively high, and the cost needs to be further reduced to expand the scope of application.

2. Complexity: Laser technology instruments often require a high degree of expertise to operate and maintain, so more technicians need to be trained.

3. Standardization: Develop standards and specifications for NH3 gas analyzers to ensure comparability and accuracy of results.

4. Data management: A large amount of real-time monitoring data requires effective management and analysis to support decision-making and policy implementation.

Conclusion

The application of NH3 gas analysis in chimney flue gas is crucial for environmental protection and public health. Laser technology brings new prospects for NH3 gas analysis, improving the accuracy, real-time and reliability of measurement. In the future, with the continuous development of technology and the continuous promotion of applications, laser technology NH3 gas analyzers will play a more important role in the field of environmental protection, helping to reduce ammonia emissions, improve air quality, and protect the environment and human health. At the same time, we also need to address the challenges in technological development to ensure the sustainable use of instruments and the effective utilization of data. I hope this blog can help readers better understand the applications and prospects of NH3 gas analyzers.more details can visit us.