In our connected world, gas sensing acts as an unseen guardian. It protects home air quality, boosts vehicle safety, and keeps factories running smoothly. Moreover, medical teams rely on it for breath analysis, while environmental agencies track pollutants in real time. From household comfort to ecological health, gas sensing drives industries toward smarter, safer practices. 10 Common Gas Sensor Technologies You Should Know:

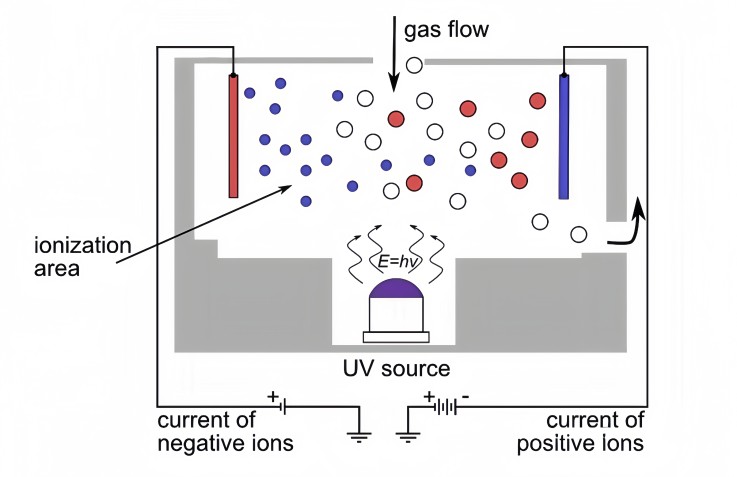

1. Photoionization Detectors (PID)

A PID uses ultraviolet (UV) light to ionize volatile molecules with ionization energy below the UV photon energy. When UV photons hit a gas, they knock off electrons. The resulting ions generate an electric current proportional to concentration. Typically, the setup of PID includes: UV lamp, ionization chamber, electrodes, sampling and signal electronics.

You’ll find PIDs at Industrial leak detection, fuel vapor monitoring at stations, chemical spill emergencies, hazardous site surveys. They excel at spotting VOCs, ammonia (NH₃), hydrogen sulfide (H₂S), hydrogen cyanide (HCN), phosphine (PH₃), etc at low parts-per-million (ppm) levels. In addition, PIDs offer fast, reliable warnings of toxic leaks.

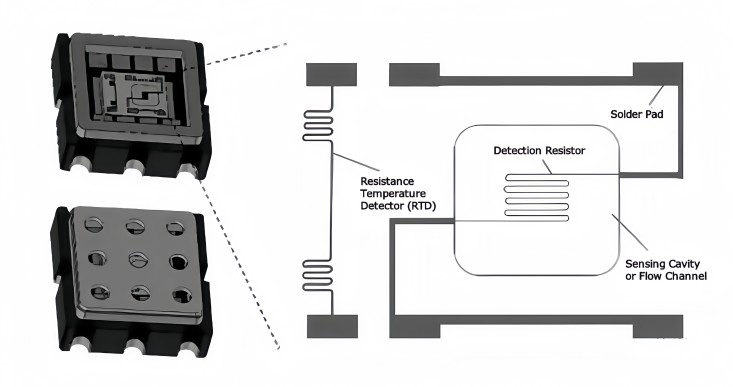

2. Thermal Conductivity Sensors

Thermal conductivity sensors measure gas by comparing heat transfer. They use a Wheatstone bridge with a heated element exposed to sample gas and a reference in clean air. When gas with different thermal conductivity enters, it cools or heats the sensing element. As a result, the bridge tips and generates a voltage. You can detect hydrogen (H2), Carbon Dioxide (CO₂), or methane (CH4) concentrations in industrial stacks or gas blends.

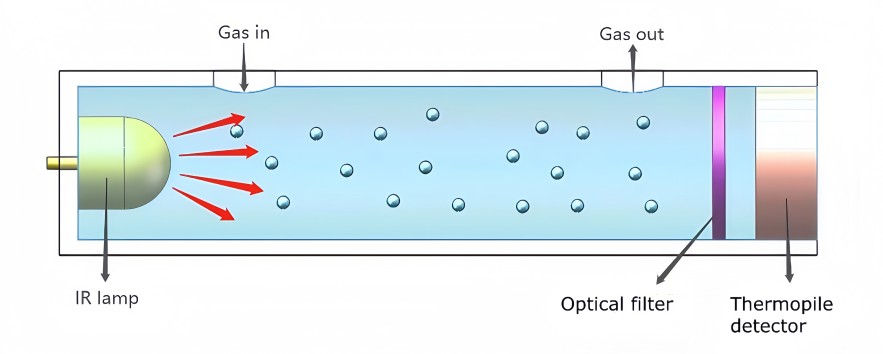

3. Non-Dispersive Infrared (NDIR) Sensors

NDIR sensors exploit specific IR absorption bands. For instance, CO₂ absorbs at 4.26 µm. Inside the sensor, an IR source sends light through the gas chamber. A filter picks one wavelength, and a detector measures the light that gets through. According to Beer–Lambert law, the drop in intensity tells you the gas concentration. NDIR excels at measuring CO₂, CO, and CH₄ with high stability over time.

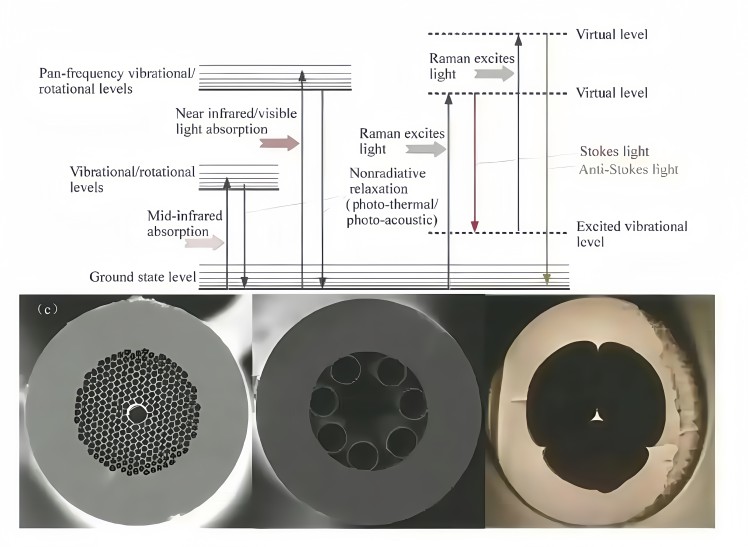

4. Fiber-Optic Gas Sensors

Light travels through special fibers that interact with surrounding gas molecules. Depending on the gas, the fiber senses changes in intensity, phase, or spectral alterations via absorption, photothermal, photoacoustic, or Raman effects.

Engineers use hollow-core photonic bandgap, antiresonant, or micro–nano-core fibers to detect flammable hydrogen (like H2) or corrosive gases. Because fibers resist electromagnetic interference, they shine in explosive environments and remote monitoring setups.

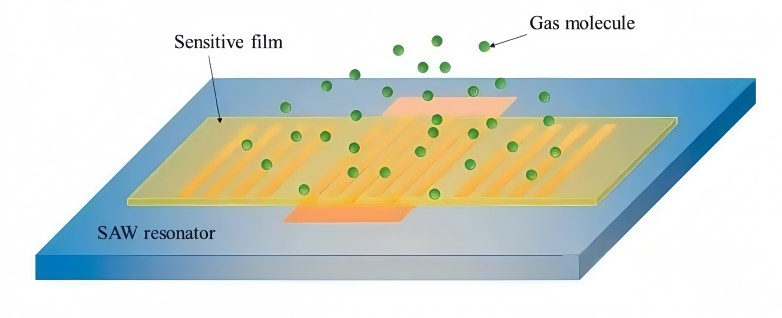

5. Surface Acoustic Wave (SAW) Sensors

SAW sensors rely on piezoelectric substrates like quartz or LiNbO₃. Interdigitated transducers launch acoustic waves along the surface. A sensitive coating—often a polymer or metal oxide—adsorbs target gas, changing mass or conductivity. Consequently, the wave’s speed or frequency shifts. We monitor that shift to gauge gas concentration. SAW works well for trace VOCs, ammonia (NH3), and hydrogen sulfide (H₂S).

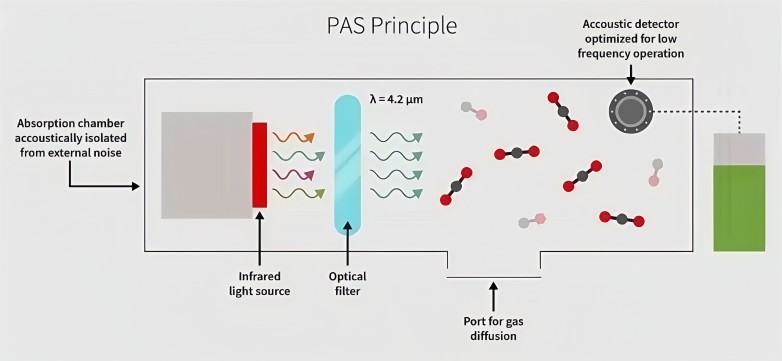

6. Photoacoustic Spectroscopy (PAS)

PAS converts light absorption into sound. A modulated laser beams into a sealed gas cell. Absorbing molecules heat up and expand, creating pressure waves. A microphone picks up these waves, and signal processing reveals the gas level.

The components of PAS include: laser source, gas cell, microphones, and signal electronics. Because PAS responds only to absorbing species, it offers ppb-level detection of CO, CO₂, and methane (CH4) in industrial emissions or lab research.

7. Laser-Based Techniques (TDLAS & CRDS)

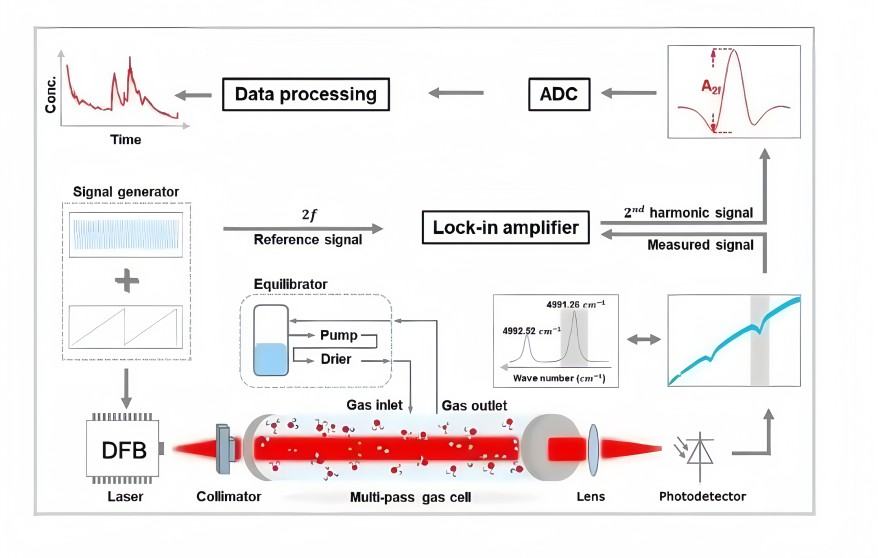

(TDLAS)

Base on Beer-Lambert law, tunable Diode Laser Absorption Spectroscopy (TDLAS) scans specific absorption lines—for example, CH₄ at 1.65 µm. It measures laser power loss to calculate concentration with high selectivity.

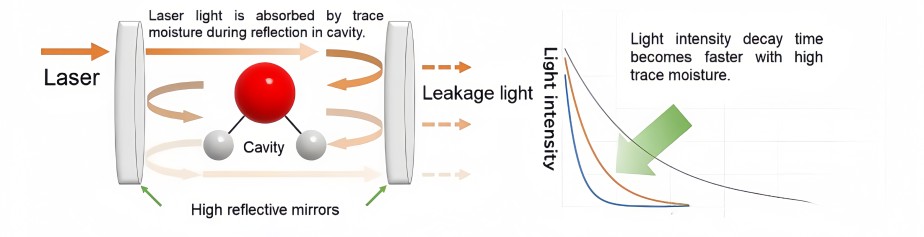

(CRDS)

In contrast, Cavity Ring-Down Spectroscopy (CRDS) traps laser light in a high-finesse optical cavity (>99.99% reflectivity). Gas absorption shortens the light’s decay time; we derive concentration from that decay. Both methods deliver ppb sensitivity and resistance to interference.

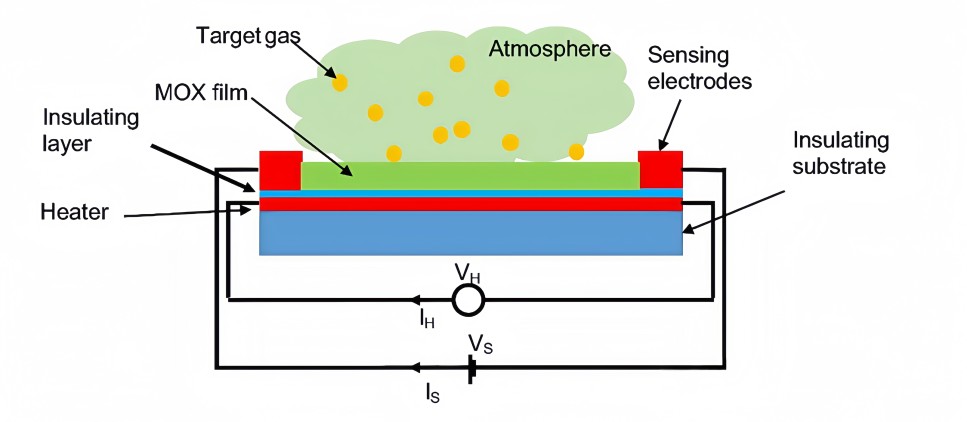

8. Metal-Oxide Semiconductor (MOS) Sensors

MOS sensors use heated films of SnO₂ or ZnO. When a reducing gas like CO or H₂ lands on the hot surface, it transfers electrons and changes the oxide’s conductivity. The sensor’s electronics then translate that change into a gas concentration reading.

MOS devices detect CO, CH₄, alcohols, formaldehyde; common in low-cost, high-sensitivity consumer devices. Meanwhile, MOS sensors suit portable CO detectors, breathalyzers, and low-cost air-quality monitors in smart homes.

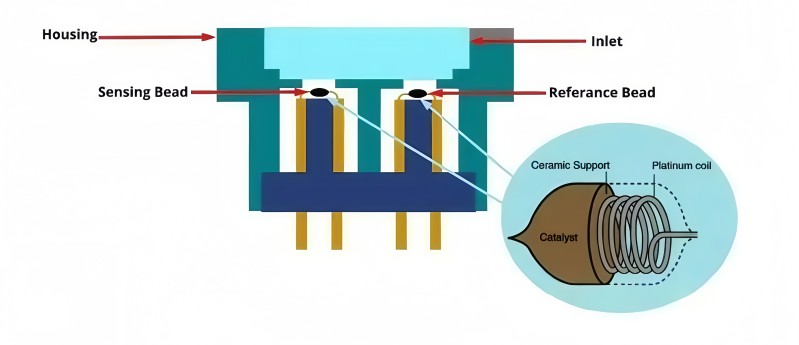

9. Catalytic (Pellistor) Sensors

Pellistors feature a catalyst-coated coil or bead. When combustible gas contacts the hot catalyst (platinum or palladium), it burns and releases heat. That heat raises the coil’s resistance in a Wheatstone bridge, producing a measurable output. These sensors detect methane, propane, and hydrogen leaks. They excel in industrial safety systems and household gas alarms.

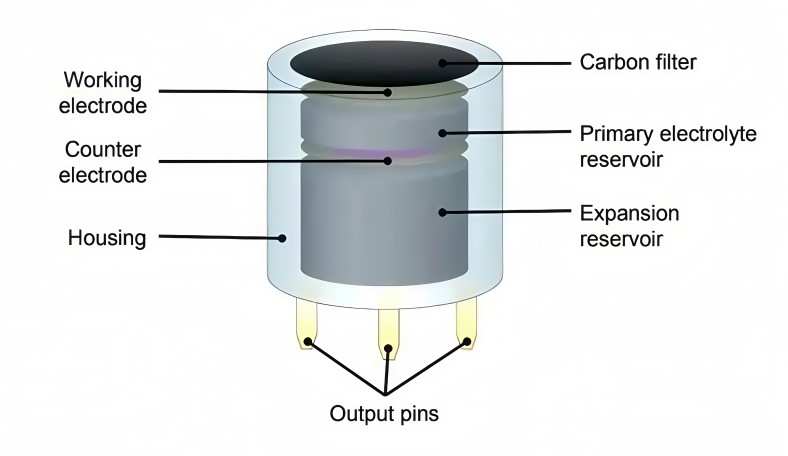

10. Electrochemical Sensors

Electrochemical cells drive redox reactions at electrodes. In a polarised sensor, a constant voltage drives the reaction—say, CO oxidizing at the working electrode. The resulting current scales with gas concentration.

Galvanic cells, however, generate current spontaneously: oxygen reduces at one electrode, while the other oxidizes lead. Both types deliver accurate readings for O₂, CO, H₂S, and SO₂ in confined spaces.

Choosing the Right Method

When selecting a sensor, consider these factors:

- Target Gas & Selectivity: Single gas vs. multi-gas applications.

- Detection Range: From ppb to percent levels.

- Response Time: Critical for safety alarms vs. steady-state control.

- Environment: Temperature, humidity, and EMI exposure.

- Maintenance & Cost: Calibration needs and lifespan.

Moreover, think about integration: some sensors plug into IoT networks, while others need dedicated analyzers. Balance performance, price, and practicality to fit your project.

Conclusion

In summary, these ten methods form the toolkit for modern gas detection. Each brings unique strengths to applications ranging from home safety to industrial automation. By understanding their principles and trade-offs, you can choose the right technology to keep systems running smoothly and securely.