Why do GFC-IR CO2 Gas Sensors matter in emission control? These Gas Filter Correlation Infrared Technology-empowered sensors are unmatched in CO2 measurement accuracy.

Critical elements such as enhanced IR detectors, particular wavelength filters and sophisticated signal processing algorithms operate in synergy. They transform IR interactions into specific CO2 figures.

In cases where emission control is high, such sensors stand as sentries of compliance to ensure that real-time accurate information for environmental stewardship are provided.

All About GFC-IR CO2 Gas Sensors!

· Basic principles of GFC-IR CO2 Gas Sensors

Infrared Absorption

GFC-IR sensors harness IR radiation for CO2 detection. Employing dual-wavelengths ensures high-precision readings. Optical filters refine the sensor’s focus, capturing specific IR frequencies.

Advanced electronics amplify signals, while minimal interference enhances accuracy. Robust design ensures consistent performance, vital for critical applications.

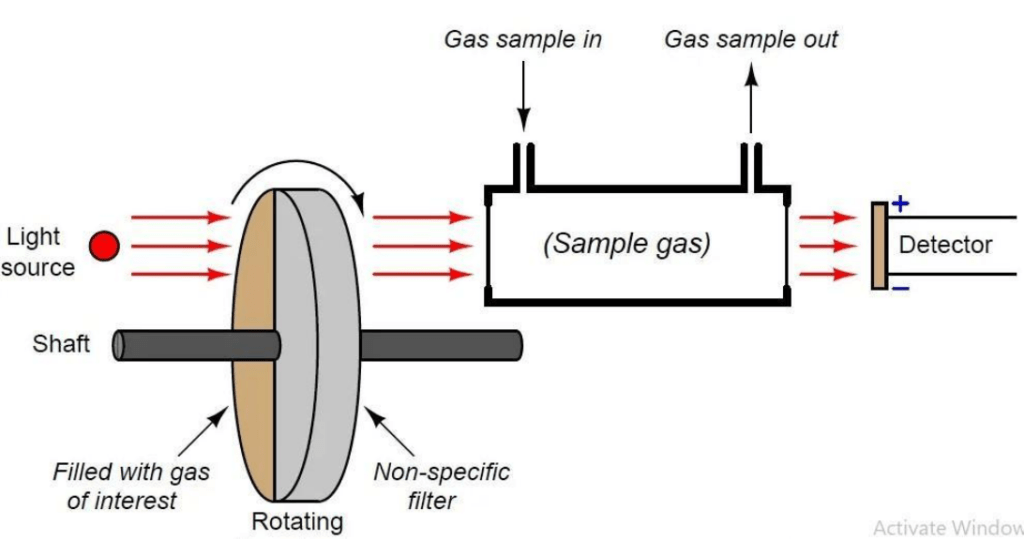

Gas Correlation

Utilizing a gas-specific algorithm, GFC-IR sensors accurately quantify CO2. Incorporating spectral analysis, these sensors discern CO2 presence amidst complex backgrounds.

Calibration leverages known gas samples, ensuring unparalleled precision. Real-time analysis enables prompt responses, crucial in dynamic environments. Continuous monitoring atmosphere guarantees reliability in diverse settings.

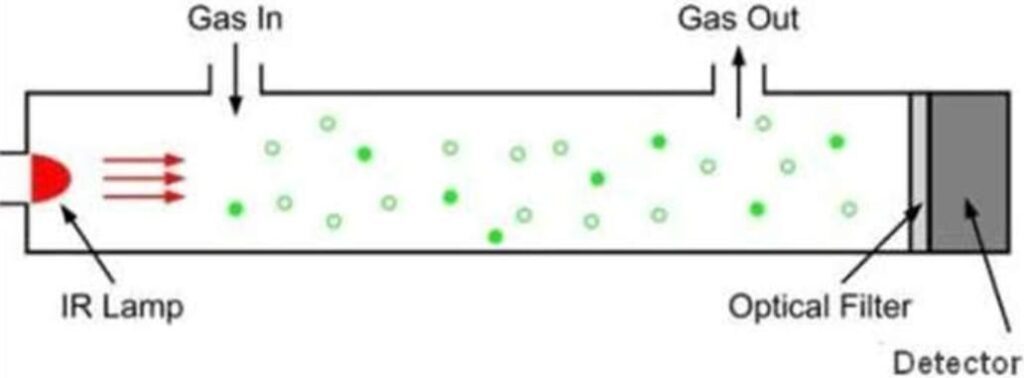

NDIR Technology

NDIR in GFC-IR sensors revolutionizes CO2 measurement. Utilizing non-dispersive infrared, the technology ensures selectivity and longevity. An innovative optical chamber enhances gas interaction, resulting in precise readings. Electronic modulation stabilizes the output, mitigating environmental impacts. Auto-calibration maintains accuracy over prolonged use, a key advantage.

Emission Monitoring

Tailored for emission surveillance, GFC-IR sensors offer unmatched precision. Real-time data acquisition aids in environmental compliance. Advanced algorithms filter out non-target gases, focusing solely on CO2. Long-term stability minimizes maintenance needs, a cost-effective feature. Essential for industrial applications, these sensors uphold rigorous standards.

Gas Quantification

GFC-IR’s precise quantification ability is pivotal in various sectors. Employing high-sensitivity components, the sensor accurately measures CO2 levels. Enhanced data processing translates to quicker, reliable readings. Adaptable to fluctuating conditions, it maintains performance consistency. Integral in safety and environmental monitoring, this technology stands as a cornerstone in gas detection.

· How GFC-IR CO2 Gas Sensors differ from other gas sensors?

Enhanced Sensitivity

GFC-IR sensors excel in sensitivity, eclipsing rivals. Precision optics and advanced IR tech converge, detecting minute CO2 variations. Superior electronic integration amplifies signal fidelity. Adaptive algorithms decipher subtle fluctuations, a leap in sensor technology. Resilience in diverse conditions sets GFC-IR apart, a hallmark of innovation.

Filter Correlation

Unmatched in filter correlation, GFC-IR stands distinct. Utilizing refined spectral analysis, it discerns CO2 with unparalleled precision. Sophisticated filter designs isolate target gas signatures.

Continuous adaptation to environmental changes ensures consistent accuracy. This technological prowess in filter power plant application defines GFC-IR’s superiority in gas detection.

High Accuracy

Precision in GFC-IR Ensors is unmatched. Rigorous calibration against known standards ensures impeccable accuracy. Advanced circuitry stabilizes readings, countering external influences.

Each sensor undergoes stringent testing, affirming its precision. High accuracy is GFC-IR’s promise, a beacon of reliability in gas sensing.

Longer Lifespan

Durability defines GFC-IR sensors, outlasting peers. Ingenious design resists wear, promising extended service. Regular self-checks maintain optimal performance. Minimal maintenance requirement underscores its longevity. Lifespan extension, a testament to GFC-IR’s robust construction, offers long-term reliability, crucial for enduring applications.

Stable Calibration

Calibration stability is GFC-IR’s forte. Advanced algorithms ensure consistent accuracy over time. Regular auto-calibration negates drift, a common sensor ailment. Resilience to environmental shifts preserves calibration integrity. This steadfast calibration approach underlines GFC-IR’s commitment to reliable, long-term gas detection.

· The role of GFC-IR CO2 Gas Sensors in emission control!

Pollution Reduction

GFC-IR CO2 Gas Sensors significantly contribute to pollution reduction. Their precise detection of CO2 levels aids in controlling emissions from industrial sources. Advanced infrared technology pinpoints CO2 presence. This results in targeted emission reduction strategies.

Industries employ these sensors to meet environmental standards. Reducing atmospheric CO2 contributes to global efforts against climate change. GFC-IR sensors are thus pivotal in pollution mitigation strategies.

Compliance Monitoring

GFC-IR CO2 Gas Sensors are essential for compliance monitoring. They provide accurate data needed for adhering to environmental regulations. Continuous CO2 level monitoring ensures industries stay within legal limits. These sensors are key in reporting emission levels to regulatory bodies.

Their reliability makes them a trusted tool for compliance officers. Regular data from these sensors helps in maintaining environmental stewardship.

Environmental Protection

Environmental protection is impossible without GFC-IR CO2 Gas Sensors. They promote maintaining air quality by monitoring CO2 emissions. In diverse eco-sensitive areas, they are used to monitor pollution levels. These sensors are used by industries for minimalizing their environmental impact.

Precise measurement of CO2 helps the development of viable contamination control methodologies. It is a step in the direction of eco-friendly practices.

Data Accuracy

The data accuracy is a key feature of GFC-IR CO2 Gas Sensors. They have an accurate CO2 measurement as a result of its high infrared technology. This level of accuracy is crucial for environmental assessments and formulating policy. Data helps industries to take wise decisions regarding emission control.

As a result, proper CO2 readings contribute to the implementation of appropriate measures against pollution. Such sensors offer the reliable information that is required for environmental management.

Continuous Monitoring

Continuous monitoring is one of the most prominent functions of GFC-IR CO2 Gas Sensors. They offer up to date CO2 level measured values needed for timely valid corrective actions.

Their 24-hour analyzer operation supports industries in real time monitoring of emission.

This continuous flow of data is indeed priceless in keeping high standards for environment. It allows for CO2 emission control, which is vital to maintain ecological balance.

The Technology Behind GFC-IR CO2 Gas Sensors!

· Infrared Source

GFC-IR CO2 gas sensors leverage a cutting-edge infrared source. Emitting rays, the source interacts with CO2 molecules uniquely. Advanced optics focus beams precisely. Heat dissipation is optimized, enhancing longevity. Spectral purity ensures accurate CO2 detection. Engineers have miniaturized components, boosting efficiency. Innovations in material science contribute significantly to performance.

· Sample Chamber

In GFC-IR CO2 gas sensors; the sample chamber is a pivotal component. Crafted for precision, it contains CO2 for analysis. Airflow dynamics within are finely controlled. Chamber material resists corrosion, ensuring accuracy over time. Ingenious design minimizes contamination risks. The chamber’s volume and shape are meticulously calculated for optimal gas interaction.

· Wavelength Filter

Key to GFC-IR CO2 sensors is the wavelength filter. Selectively permitting specific IR frequencies, it isolates CO2 signatures. Filter design combats noise, sharpening detection.

Advanced materials yield unparalleled filter durability. Calibration is fine-tuned for environmental variations. Filter integration with other components is seamless, enhancing overall sensor performance.

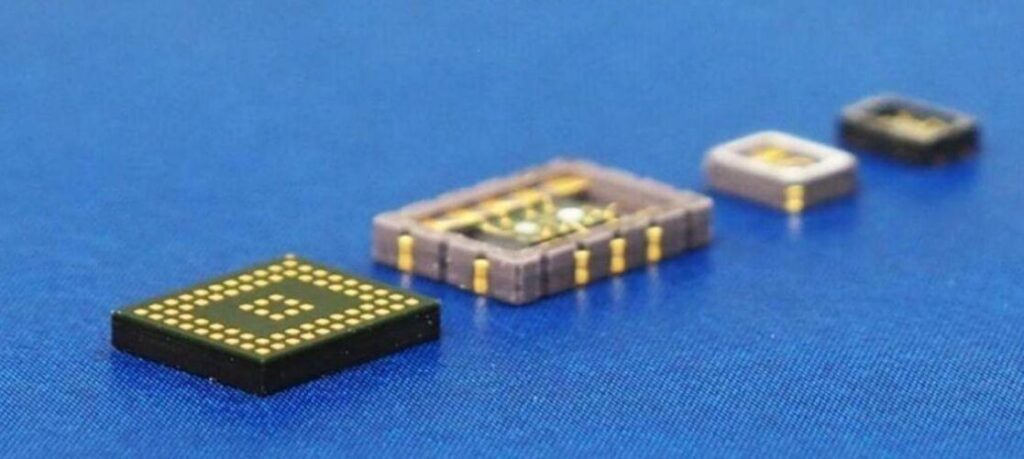

· IR Detectors

IR detectors in GFC-IR CO2 sensors are state-of-the-art. They translate IR interactions into electrical signals with high fidelity. Sensitivity to minute CO2 changes is paramount. Noise reduction techniques are employed extensively. Detector response time is rapid, ensuring timely readings. Integration with circuitry is designed for signal clarity and strength.

· Signal Processing

The system’s digital core executes complex computational tasks. Data conversion from analog to digital is seamless. Adaptive algorithms account for ambient variables.

This ensures consistent CO2 measurements. The processor’s compact design maximizes space efficiency. Energy consumption is optimized for prolonged operational life. Firmware updates enhance functionality over time, adapting to new research findings.

| Feature | GFC-IR CO2 Gas Sensors | Comparison Tech A | Comparison Tech B | Comparison Tech C | Comparison Tech D | Comparison Tech E |

| Infrared Source | Non-dispersive (NDIR) | Dispersive IR | Laser Diode | Electrochemical | Catalytic | Photoacoustic |

| Sample Chamber | Hermetically sealed | Open Path | Flow-through | Microenvironment | Diffusive | Single-pass |

| Wavelength Filter | Narrow-band (4.26 µm) | Broadband | Tunable | Fixed (specific) | Multi-spectral | None |

| IR Detectors | Dual channel | Single channel | Pyroelectric | Thermopile | Photodiode | MEMS |

| Signal Processing | Advanced algorithms | Basic conversion | FFT analysis | Voltage change | Catalytic effect | Acoustic response |

| Accuracy | ±50 ppm | ±100 ppm | ±75 ppm | ±150 ppm | ±200 ppm | ±60 ppm |

| Response Time | < 10 seconds | 15 seconds | 5 seconds | 30 seconds | 20 seconds | 12 seconds |

| Application Suitability | Indoor air quality, Safety monitoring | Outdoor environment | Industrial emissions | Portable devices | Hazardous areas | Research labs |

Advantages of Using GFC-IR CO2 Gas Sensors in Industrial Settings!

· Reliable Readings

GFC-IR CO2 gas sensors offer unwavering accuracy in industrial environments. Equipped with advanced optics, they ensure precise CO2 measurement. Robust algorithms interpret IR signals reliably.

Even in fluctuating temperatures, their readings remain consistent. Technological refinements minimize errors. The sensors’ reliability is paramount in critical applications, guaranteeing dependable data for decision-making.

· Low Drift

In GFC-IR CO2 sensors, low drift is a key advantage. Enhanced calibration maintains accuracy over extended periods. Advanced materials reduce sensor degradation. Engineers have minimized drift to near-negligible levels. Continuous performance checks ensure consistency.

This stability is crucial for long-term industrial monitoring, making recalibration intervals longer, saving time and resources.

· Minimal Interference

GFC-IR CO2 sensors excel in reducing environmental interference. Unique filter designs isolate CO2 readings from pollutants. Advanced circuitry shields sensors from electromagnetic disturbances. Innovative housing blocks out irrelevant IR wavelengths. This results in unadulterated CO2 data, essential for precise environmental assessments in complex industrial settings.

· Durable Design

Durability defines GFC-IR CO2 sensors. Constructed with robust materials, they withstand harsh industrial conditions. Protective coatings guard against corrosive elements.

Thermal management extends component life. Design innovations ensure longevity even in high-vibration environments. Such resilience is crucial for industrial applications, promising long-term reliability without frequent replacements.

· Easy Integration

GFC-IR CO2 sensors are designed for effortless integration into industrial systems. Their compact form factor allows flexible installation. Compatible interfaces facilitate connection with various control systems. User-friendly calibration processes simplify maintenance.

Software adaptability ensures seamless integration with existing monitoring networks. This ease of integration streamlines operational workflows, enhancing overall efficiency in industrial environments.

Applications of GFC-IR CO2 Gas Sensors in Different Industries!

· Energy Sector

In the energy sector, GFC-IR CO2 sensors play a pivotal role. They monitor emissions at power plants, ensuring regulatory compliance. Advanced optics allow for precise gas analysis. Robust design withstands extreme conditions in energy production. Real-time data aids in optimizing combustion processes. Essential for carbon capture initiatives, they contribute to sustainable energy practices.

· Petrochemicals

GFC-IR CO2 sensors are vital in petrochemical industries. They detect CO2 levels in refining processes, enhancing safety. Precise measurements ensure process efficiency, vital for optimal yield. Durable sensors withstand corrosive environments typical in petrochemical plants. Real-time monitoring aids in leak detection, a critical aspect of operational safety.

· Pharmaceuticals

In pharmaceuticals, GFC-IR CO2 sensors ensure controlled environments. Essential for drug manufacturing, they monitor CO2 in fermentation processes. Accuracy is key in maintaining product quality. Their use in cleanrooms ensures contamination-free conditions. Sensors’ reliability supports compliance with stringent health regulations. They play a crucial role in vaccine production, where stable environments are mandatory.

· Manufacturing

Manufacturing industries leverage GFC-IR CO2 sensors for environmental monitoring. They ensure worker safety by detecting harmful CO2 levels. Integrated in HVAC systems, sensors maintain air quality. In automotive manufacturing, they monitor emissions during vehicle testing. Their precision is vital for maintaining industry standards and regulatory compliance.

· Food & Beverage

In the food and beverage sector, GFC-IR CO2 sensors are indispensable. They dust monitor carbonation levels in beverages, ensuring product consistency. Used in packaging, sensors detect spoilage gases, extending shelf life. In controlled atmosphere storage, they maintain optimal conditions for perishables. Their accuracy is crucial in meeting food safety standards.

Installation and Maintenance of GFC-IR CO2 Gas Sensors!

· Regular Calibration

Regular calibration of GFC-IR CO2 gas sensors is essential. Precision tools adjust sensor accuracy, ensuring consistent readings. Calibration intervals are strategically scheduled for minimal operational disruption. Advanced software assists in calibration, reducing human error.

This process is vital for maintaining data integrity, especially in high-stake industrial environments where accuracy is paramount.

· Firmware Updates

Firmware updates in GFC-IR CO2 sensors enhance functionality. They introduce new features and improve existing ones. Updates ensure sensors keep pace with technological advancements.

Remote update capabilities facilitate easy implementation. Regular updates safeguard against potential cyber security threats. This continuous improvement cycle ensures sensors remain cutting-edge in performance and security.

· Component Checks

Component checks are integral to GFC-IR CO2 sensor maintenance. Regular inspections identify wear and potential faults early. Specialized tools assess sensor components’ functionality.

Proactive replacement of worn parts prevents unexpected failures. Such diligence extends sensor lifespan, ensuring reliability. These checks are crucial for uninterrupted operation in critical industrial processes.

· Cleaning Protocols

Adhering to specific cleaning protocols is crucial for GFC-IR CO2 sensors. Specialized cleaning agents are used to avoid damage. Techniques are employed to prevent contamination.

Regular cleaning ensures optimal sensor performance. It also extends the operational life of the sensor. Following these protocols is key to maintaining sensor accuracy and reliability.

· Environmental Adjustments

Environmental adjustments are necessary for optimal functioning of GFC-IR CO2 sensors.

Sensors are fine-tuned to specific operating conditions. Adjustments account for temperature, humidity, and other environmental factors. This customization ensures accurate CO2 readings across diverse settings. Such adaptability is crucial for sensors used in varying industrial environments.

Conclusion

Emission control is not possible without GFC-IR CO2 Gas Sensors. Their accuracy, longevity and state-of-the art technology make them major players in the establishment of environmental standards.

They provide industries with steady solutions for mitigation in managing emissions. More information and solutions regarding GFC-IR CO2 Gas Sensors can be found on ESEGAS. Own now the advance technology in emission controlling.