(ESEGAS Zirconia Oxygen Analyzer)

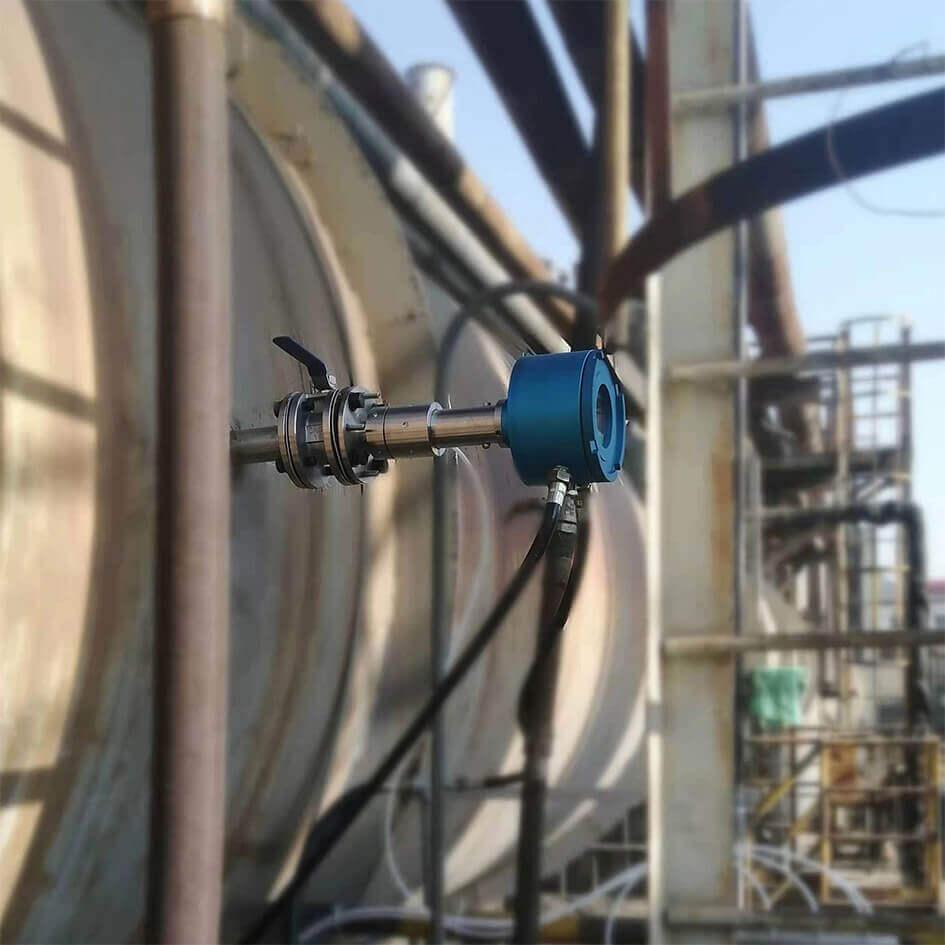

ESEGAS is proud to unveil our next-generation zirconia oxygen analyzers. The ESE-Z-100 is engineered for precision, flexibility, and reliability in industrial applications. Available in two smart configurations, our analyzers adapt seamlessly to any environment:

- All-in-One Unit – Integrated transmitter and probe in a compact, streamlined design.

- Split-Type System – Transmitter and probe separated for flexible installation and easier maintenance.

Both models let you select customizable colors and choose between explosion-proof or standard options to meet your safety needs.

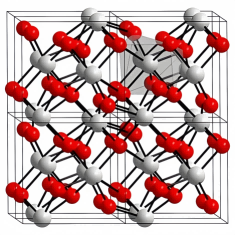

How Does a Zirconia Oxygen Analyzer Deliver Precision Control?

Leveraging zirconium dioxide (ZrO₂) solid-electrolyte technology, these analyzers measure oxygen ions at high temperatures (typically 600–900 °C). The fast-response sensor uses Nernst-equation-based readings to deliver precise, real-time O₂ measurements. As a result, plants gain tighter combustion control, improved thermal efficiency, and significantly lower CO and NOₓ emissions

Can a Zirconia Oxygen Analyzer Combine Flexibility, Safety, and Aesthetics in One System?

Thanks to the split-type design, you can position the probe right in flue stacks or harsh environments while keeping the transmitter in a protected area. And with customizable housings and explosion-proof options, your analyzer won’t just perform—it will fit into your workspace and compliance standards perfectly.

What Real-World Benefits Does a Zirconia Oxygen Analyzer Offer?

Combustion Optimization

In boilers and kilns, even a 1% reduction in excess oxygen can cut fuel usage by 0.5–1%. And because zirconia sensors respond in under 3 seconds, they support tight closed-loop control via DCS or PLC systems.

Emissions Reduction

By maintaining ideal oxygen levels, operators avoid incomplete combustion (reducing CO and soot) and limit high-temperature NOₓ formation.

Equipment Longevity

Stable combustion temperatures reduce thermal stress on boilers, refractories, and stacks, which lowers maintenance costs and extends equipment life.

Regulatory Compliance

Fast, accurate measurements support environmental limits and workplace safety, especially in explosion-prone zones. Explosion-proof models ensure full compliance with hazardous-area regulations.

Which Industries Can Best Leverage a Zirconia Oxygen Analyzer for Optimal Combustion Control?

ESEGAS zirconia oxygen analyzers serve a wide range of sectors:

- Power plants (coal, gas, biomass) – Enhance thermal efficiency and lower emissions.

- Petrochemical & refining furnaces – Optimize feedstock combustion and yield.

- Steel, cement, glass kilns – Control atmosphere for quality output.

- Waste incineration – Maintain safe, complete burns and regulatory compliance.

- Industrial gas generators – Ensure oxygen purity and minimize operational costs

Why Is the ESEGAS Zirconia Oxygen Analyzer Engineered for Tough Industrial Conditions?

With rugged ceramic sensors, fast 1–3 sec response times, and resistance to corrosion and thermal cycling, ESEGAS zirconia analyzers meet the toughest industrial demands. They offer:

- Broad measurement range: ppm to 25% O₂

- Minimal drift and low maintenance

- Optional humidity measurement for flue gas control

Conclusion

In industrial combustion, monitoring oxygen isn’t a bonus—it’s essential. By choosing ESEGAS’s configurable zirconia oxygen analyzers, you gain:

- Precise, real-time combustion control

- Lower fuel use and emissions

- Safer operations and regulatory compliance

- Durable performance in harsh conditions

Step into the future of combustion management. ESEGAS’s next-gen zirconia oxygen analyzers deliver control, clarity, and peace of mind—for any environment, any industry.

If you want to know more details, contact with us please!