Inefficient HVAC performance can remain hidden—until safety, cost, or comfort is compromised. Gas analyzers offer the unseen control to fix that.

Gas analyzers are essential in HVAC systems because they detect and quantify gases like CO, CO₂, and O₂, ensuring optimal combustion, indoor air quality, and regulatory compliance.

While this overview confirms their importance, several critical questions still need to be addressed—especially regarding energy efficiency, safety, and future HVAC technologies.

What Gases Do Gas Analyzers Monitor in HVAC Systems?

Unseen gases can silently erode HVAC performance—or worse, threaten occupant safety. Monitoring them isn’t optional—it’s essential.

Gas analyzers in HVAC systems commonly monitor carbon monoxide (CO), carbon dioxide (CO₂), oxygen (O₂), and sometimes nitrogen oxides (NOₓ) or sulfur dioxide (SO₂), depending on the application. These gases directly impact system efficiency, air quality, and safety compliance.

Accurate gas detection is the foundation of any efficient and safe HVAC setup. Carbon monoxide (CO), a toxic byproduct of incomplete combustion, is especially dangerous in enclosed environments and must be continuously tracked. Carbon dioxide (CO₂) levels provide insights into air quality and occupancy ventilation needs, while oxygen (O₂) levels help diagnose combustion efficiency—too little O₂ indicates poor burning, too much suggests energy waste. For industrial or commercial HVAC systems, analyzers may also measure nitrogen oxides (NOₓ) and sulfur dioxide (SO₂) to manage emissions and adhere to regulatory limits.

| Gas | Source | Impact on HVAC | Why It Matters |

| CO (Carbon Monoxide) | Incomplete combustion of fuel | Indicates faulty burners or poor combustion | Highly toxic; crucial for safety |

| CO₂ (Carbon Dioxide) | Human respiration, combustion | Used to assess ventilation and occupancy levels | Impacts indoor air quality; linked to comfort and health |

| O₂ (Oxygen) | Ambient air | Monitors combustion efficiency | Helps fine-tune air/fuel ratio |

| NOₓ (Nitrogen Oxides) | High-temperature combustion | Monitors emissions in industrial HVAC | Regulated pollutant; contributes to smog formation |

| SO₂ (Sulfur Dioxide) | Combustion of sulfur-containing fuels | Used in specific industrial HVAC applications | Corrosive; affects equipment and health |

Advanced instruments, like those developed by ESEGAS, are engineered for real-time, multi-gas monitoring. Their analyzers offer high sensitivity and long-term stability, making them ideal for both residential and industrial HVAC environments. With this level of insight, HVAC technicians can make data-driven decisions to fine-tune combustion systems, optimize airflow, and reduce exposure to harmful pollutants—all while maintaining compliance with evolving air quality standards.

How Do Gas Analyzers Improve HVAC Energy Efficiency?

High energy bills and wasted fuel are often symptoms of invisible inefficiencies—gas analyzers expose them with precision.

Gas analyzers help optimize HVAC system efficiency by monitoring combustion quality, adjusting fuel-to-air ratios, and minimizing energy waste. Real-time data ensures cleaner combustion and lower operational costs.

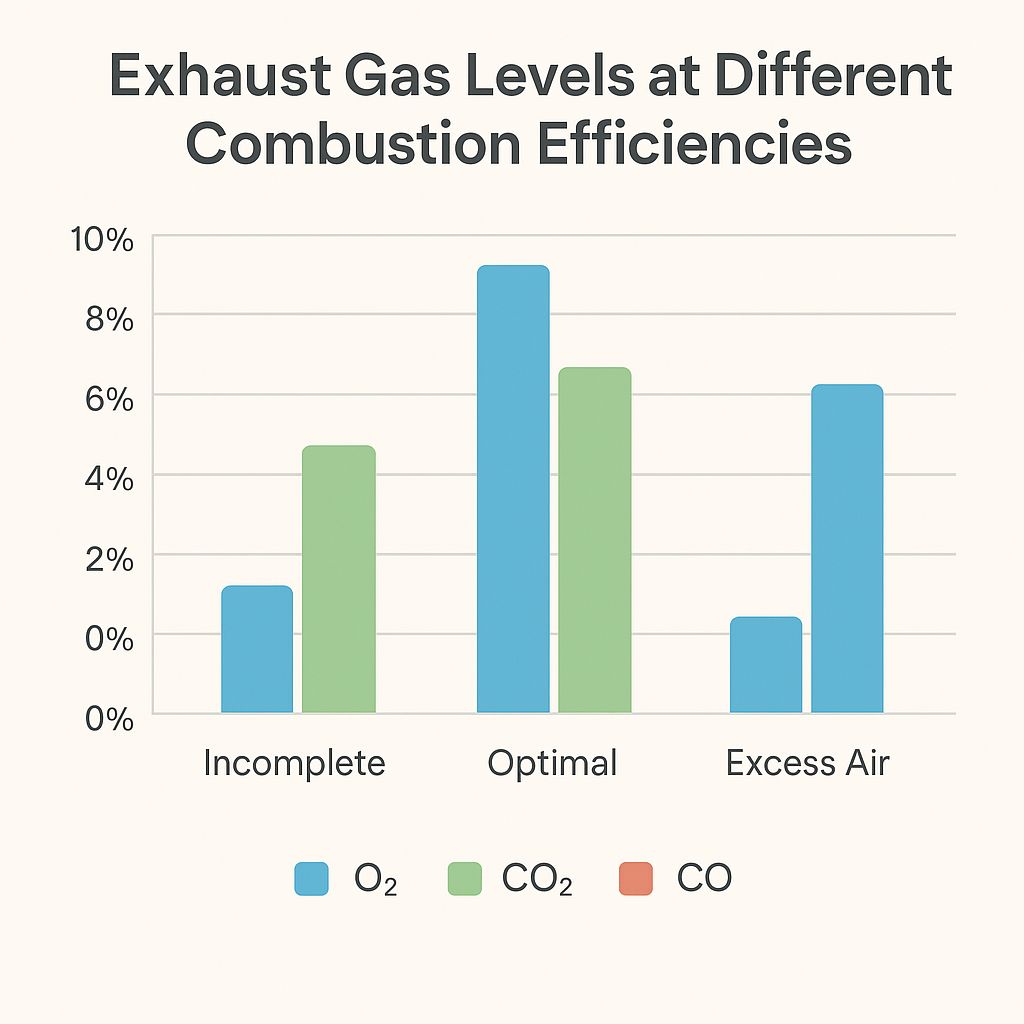

In HVAC systems—especially those involving boilers, furnaces, or other combustion processes—achieving the correct fuel-to-air ratio is key to energy efficiency. Too much air leads to heat loss through the exhaust; too little air results in incomplete combustion and higher emissions. Gas analyzers continuously measure oxygen (O₂), carbon monoxide (CO), and sometimes carbon dioxide (CO₂) in the exhaust gases. These readings allow HVAC professionals to adjust burner settings with precision.

For example, an optimized combustion process will show low CO and high CO₂, indicating that fuel is being burned cleanly. Excess oxygen, on the other hand, suggests that too much air is diluting the combustion, causing unnecessary energy loss.

Systems developed by ESEGAS stand out by offering high-sensitivity sensors and real-time feedback loops. These features enable automated controls in modern HVAC systems to make on-the-fly adjustments, drastically improving thermal efficiency. Over time, this translates into reduced fuel usage, extended equipment lifespan, and lower carbon emissions.

Ultimately, the integration of gas analyzers is not just a tool for diagnostics—it’s a proactive strategy for energy management.

What Is the Role of Gas Analyzers in HVAC Safety?

A silent leak from an HVAC system can turn deadly—unless a gas analyzer catches it first.

Gas analyzers are critical for HVAC safety because they detect hazardous gases like carbon monoxide (CO) and combustible gas leaks, providing early warnings that prevent poisoning, fires, or system failure.

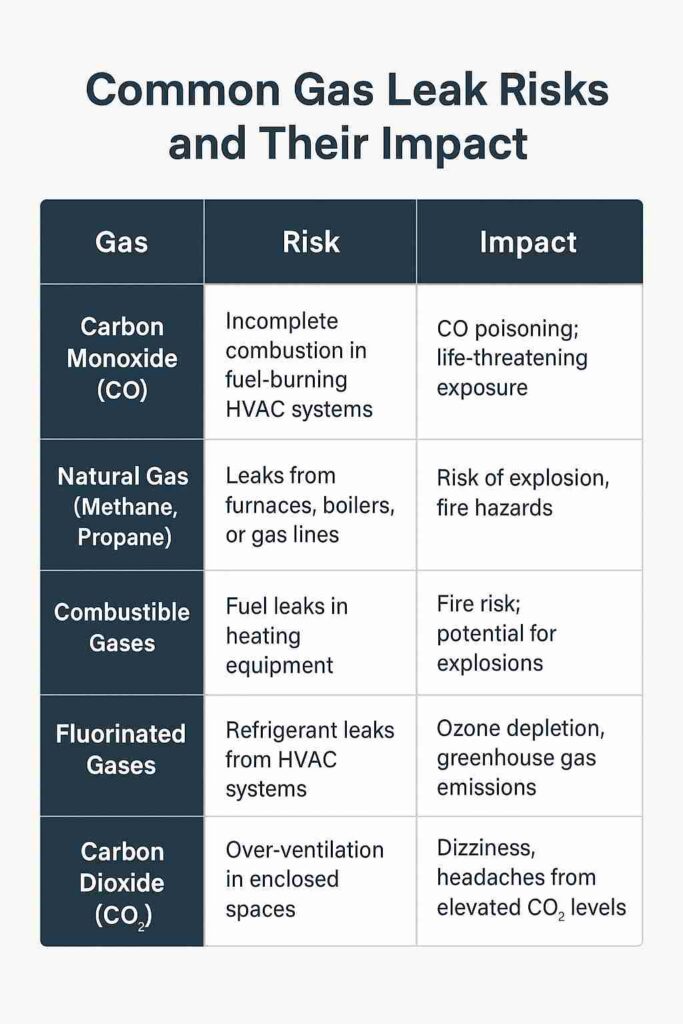

In both residential and industrial HVAC systems, safety isn’t guaranteed by design alone—it’s ensured through continuous, accurate gas monitoring. One of the most dangerous threats is carbon monoxide (CO), an odorless and colorless gas resulting from incomplete combustion. Without a gas analyzer, a CO leak can go completely unnoticed until it’s too late, leading to illness, unconsciousness, or even fatalities.

Gas analyzers also play a vital role in detecting other safety risks, such as natural gas leaks (methane or propane), which could lead to fires or explosions. By monitoring these gases in real time, analyzers can trigger automatic system shutdowns, ventilation activation, or alarm alerts via the building management system (BMS).

Advanced solutions from ESEGAS integrate seamlessly with modern HVAC safety protocols. Their analyzers offer fast-response sensors, auto-calibration, and fail-safe diagnostics, ensuring that any deviation from safe thresholds is immediately identified and addressed. This proactive detection not only protects human lives but also prevents costly damage to HVAC equipment and building infrastructure.

In short, gas analyzers act as a 24/7 safety sentinel within HVAC systems—protecting people, assets, and operations.

How Do Gas Analyzers Contribute to Smart HVAC Systems?

Traditional HVAC systems react—smart HVAC systems anticipate. Gas analyzers are the sensors that make that intelligence possible.

Gas analyzers enable smart HVAC systems by supplying real-time air quality and combustion data to automated controls, allowing dynamic optimization of ventilation, energy use, and system performance.

Modern HVAC systems are increasingly integrated into Building Management Systems (BMS) and IoT platforms. In these intelligent environments, gas analyzers act as essential input devices—feeding real-time data on oxygen (O₂), carbon dioxide (CO₂), volatile organic compounds (VOCs), and combustion byproducts into the system. This allows smart HVAC controls to make automated, adaptive decisions that would otherwise require manual intervention.

For example, when indoor CO₂ levels rise due to high occupancy, smart analyzers from ESEGAS detect the shift instantly. The BMS can then trigger ventilation dampers to open, activate additional air exchangers, or adjust fan speeds—restoring indoor air quality without human involvement. Likewise, in combustion systems, analyzers monitor flue gases continuously to adjust burner controls, ensuring optimal efficiency at all times.

Advanced analyzers by ESEGAS come equipped with features like cloud connectivity, Modbus/BACnet integration, and predictive diagnostics. This not only enhances HVAC responsiveness but also supports remote monitoring, automated alerts, and trend-based maintenance—hallmarks of truly intelligent systems.

In short, gas analyzers are not just instruments; they are the sensory network that transforms HVAC infrastructure from passive to proactive.

Conclusion

In conclusion, gas analyzers are indispensable in HVAC systems—from ensuring safety and compliance to driving energy efficiency and enabling intelligent automation. Providers like ESEGAS lead this transformation with precision instrumentation designed for today’s HVAC challenges.

if you have any questions, please contact us!