In an industry where the stakes are incredibly high, the pharmaceutical sector operates at the intersection of advanced chemistry, strict engineering standards, and unwavering regulatory oversight. Active Pharmaceutical Ingredients (APIs) are produced through multi-stage processes that are both complex and sensitive. Recently, the global landscape has shifted, with a renewed focus on stringent safety measures. The series of chemical plant accidents in China from 2016 to 2018, and the tragic 2019 explosion at the Jiangsu Tianjiayi Chemical Company that resulted in at least 78 deaths, have underscored the critical need for robust safety protocols. This has led to a tightening of regulations, pushing companies to adopt more proactive, technology-driven approaches to risk management.

At the heart of this new paradigm is the oxygen monitoring system. This technology serves a dual, mission-critical function that goes far beyond simple compliance. It acts as a silent guardian, providing continuous vigilance to ensure both plant safety and product quality. On one hand, it is an essential tool for explosion prevention, protecting personnel and assets from the volatile nature of pharmaceutical synthesis. On the other, it is a key component for quality control, safeguarding high-value products and catalysts from degradation. By integrating real-time data into process control, these systems transform risk mitigation from a static, reactive task into a dynamic, data-driven strategy.

How Does an Oxygen Monitoring System Prevent Explosions in Reactors?

The Volatile Chemistry of Pharmaceutical Synthesis

Pharmaceutical synthesis often relies on organic solvents like ethanol, acetone, and methanol. These solvents are highly volatile, and their vapors can form explosive mixtures when they combine with oxygen from the air. Even a small quantity of residual solvent vapor from a previous batch can pose a serious threat if not properly managed. The core principle of explosion prevention in a chemical reactor is the practice of inerting, where an inert gas—typically nitrogen—is used to displace oxygen and create an environment where combustion cannot occur.

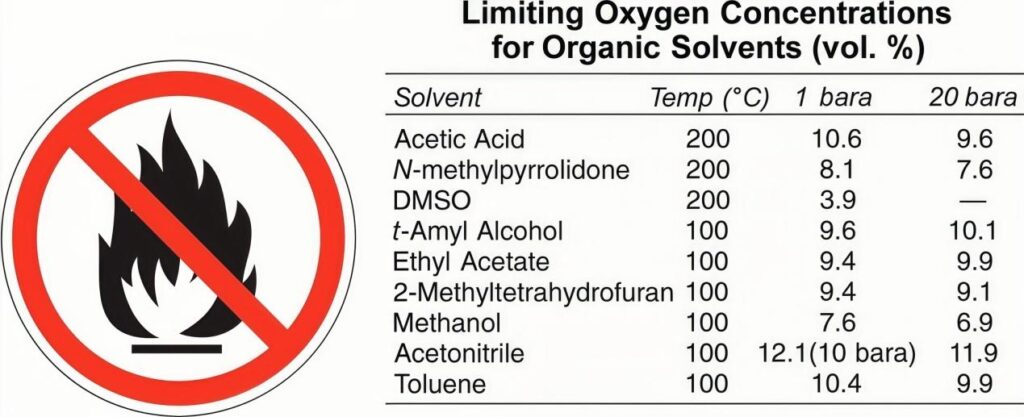

The goal is to reduce the oxygen concentration below the Minimum Oxygen Concentration (MOC), a specific threshold at which the solvent vapor will not ignite. This limit is often maintained at or below 8% oxygen concentration. Historically, some companies would simply maintain a continuous flow of nitrogen into the reactor headspace, believing this was sufficient to guarantee an inert environment. However, this is a static, resource-intensive approach. A continuous flow of nitrogen is costly, and this method provides no assurance of safety if the flow is interrupted or if a leak occurs. A sudden loss of nitrogen flow, for instance, could lead to a rapid increase in oxygen levels, creating a dangerous situation that a static system would not detect. An oxygen monitoring system represents a fundamental shift from this static operational guesswork to a dynamic, data-driven form of process control. It moves the process from simply using nitrogen to actively monitoring and controlling the oxygen level. The system’s real-time signal can be used to control the nitrogen flow, triggering an alarm or even initiating a plant shutdown if oxygen levels approach a dangerous threshold. This demonstrates that the monitoring system is not just a sensor; it is an active and indispensable component of a safety control loop.

Real-World Incidents and Preventative Measures

The tragic incidents in the Chinese chemical industry from 2016 to 2018, which led to 728 deaths, highlight the need for more robust safety protocols. These events spurred a push for stricter regulations and a shift toward technology-driven safety solutions. One specific case study details a dust explosion that occurred during the loading phase of a pharmaceutical reactor. The incident was caused by a combination of residual methanol vapor and an electrostatic discharge. Oxygen had entered the reactor along with the organic powder being charged through an open hatch, creating an explosive atmosphere in the presence of the residual solvent vapor.

This incident demonstrates that maintaining an inert environment is not a given; it must be continuously and actively verified. The incident occurred not during the core chemical reaction but during a critical operational step—the charging of raw materials. An oxygen monitoring system would have detected the air entering the reactor during the loading phase, immediately triggering an alarm and preventing the explosive mixture from forming. This underscores the importance of monitoring not just the reaction itself but also all critical, and often overlooked, stages like material charging and transfer. The evidence shows that a proactive, continuously vigilant approach is the only way to safeguard against such unforeseen risks.

How Does an Oxygen Monitoring System Improve Product Quality and Consistency?

(ESEGAS Oxygen Monitoring System on-site)

Controlling Oxidation and Protecting High-Value Catalysts

Beyond its role in safety, oxygen monitoring is a cornerstone of product quality. During pharmaceutical synthesis, oxygen exposure can lead to unwanted oxidation side reactions, creating impurities that affect the purity of the Active Pharmaceutical Ingredient (API). The presence of these by-products poses a direct risk to patient health, as they can be toxic or reduce the efficacy of the drug. By maintaining a precise, oxygen-free environment, a monitoring system prevents these side reactions, ensuring the final API meets the stringent quality specifications required for patient safety and regulatory approval.

Furthermore, oxygen is a powerful deactivator of sensitive catalysts, such as palladium and platinum, which are crucial for hydrogenation reactions. These heterogeneous catalysts, often adsorbed on high-surface-area materials like activated carbon, facilitate the reaction by lowering its activation energy. When they are exposed to oxygen, they can become irreversibly deactivated, halting the reaction or leading to incomplete conversions. This deactivation has a direct and significant economic impact. Palladium and platinum are noble metals, making them extremely expensive. If a batch is ruined because of a deactivated catalyst, it is not just the loss of the product but also the financial loss of the catalyst itself, which is a significant capital cost. An oxygen monitoring system, therefore, provides a direct return on investment by protecting these high-value assets and raw materials. It prevents costly re-runs and material waste, shifting the perspective of the system from a pure safety expense to a strategic tool for financial prudence and operational excellence.

Ensuring Consistency Across Batches

The reputation and regulatory standing of a pharmaceutical company are tied to its ability to produce consistent products that meet the same quality standards batch after batch. Inconsistencies can lead to product recalls, regulatory scrutiny, and a loss of market trust. In many synthesis processes, particularly in bioprocessing, variables like dissolved oxygen concentration must be tightly controlled to achieve consistent outcomes. Research shows that maintaining a defined dissolved oxygen setpoint in a stirred suspension bioreactor can significantly increase cell proliferation and final product yield.

Continuous oxygen monitoring eliminates a key variable that can cause such inconsistencies, ensuring that every batch meets the same quality standards as the last. In processes like brewing, for example, oxygen levels have a direct impact on yeast activity and the final product’s flavor profile. The ability to precisely control oxygen levels based on real-time data allows for immediate adjustments that can save a batch and ensure consistent quality, reducing waste and improving overall production economics.

How Can a Continuous Oxygen Monitoring System Optimize Your Production Process?

(ESEGAS Oxygen Monitoring System)

Real-Time Data for Smart Efficiency

Modern oxygen monitoring systems do more than just alert for danger; they provide continuous, real-time data that enables significant operational efficiencies. One of the most impactful applications of this data is in the optimization of inert gas purging. The analysis shows that in the past, a common practice was to use a constant, high flow of nitrogen to ensure safety, a method that is inherently wasteful and costly.

With an integrated oxygen monitoring system, process engineers can dynamically adjust the nitrogen flow to maintain the exact minimum oxygen concentration required for safety. This intelligent, responsive control turns inerting from a static, resource-intensive process into an efficient one. It maintains the required safety margin while simultaneously reducing the consumption of a costly consumable, like nitrogen, thereby improving the bottom line. This creates a powerful synergy between safety and sustainability, transforming the investment from a pure cost center into a strategic asset that enhances both safety and financial performance.

Fine-Tuning Complex Reactions

In some chemical reactions, oxygen is not a contaminant to be eliminated but a crucial reactant that must be precisely controlled. This is particularly true for partial oxidation reactions, which are used to produce valuable chemicals like methanol. For these processes, a simple “oxygen-free” environment is not sufficient. The process requires a system capable of accurately measuring and controlling oxygen within a narrow, non-zero range to ensure optimal performance and selectivity.

Research has shown that for certain chemical processes, the properties of the final product can be “finely tuned” by precisely modulating the residual oxygen content. This requires a level of precision that is only possible with continuous, real-time monitoring and an automated control loop. For example, in the production of reduced graphene oxide, controlling the degree of residual oxidation with hydroiodic acid allows for the careful tailoring of the material’s electrical properties. This level of precision is invaluable and demonstrates how an oxygen monitoring system moves beyond basic safety to become a sophisticated tool for advanced process optimization and product customization.

What Chinese Regulatory Standards Mandate Oxygen Monitoring for Pharmaceutical Reactors?

The Urgency of Regulatory Compliance

The recent history of industrial accidents has directly impacted the regulatory landscape in China. The Chinese government has responded with more stringent safety regulations, a move that is reshaping the chemical and pharmaceutical industries. The new mandatory national standard, General Code for Standardized Safe Production in Hazardous Chemical Enterprises (GB 45673-2025), emphasizes the need for companies to fulfill their safety responsibilities, mitigate major risks, and adopt advanced “digital and intelligent safety management systems”.

These new regulations are a direct response to past tragedies. They signal a shift from basic, reactive compliance to a more proactive, technology-driven approach to safety. A company’s ability to demonstrate a robust, real-time safety infrastructure is no longer a “nice-to-have” but a mandatory requirement. At its core, an intelligent system is built on real-time data. In the context of reactor safety, the most critical data point is the oxygen level. Therefore, an oxygen monitoring system is not just one component among many; it is the fundamental sensor layer that makes a “smart” safety system possible. Without real-time, continuous oxygen data, a digital safety system cannot identify major risks, cannot trigger automated alarms or shutdowns, and cannot provide the necessary documentation for compliance verification. Investing in a robust oxygen monitoring system is the first, non-negotiable step toward meeting China’s new, more demanding regulatory landscape.

Conclusion: The Future of Safety and Quality in Pharmaceutical Chemical Reactors

Oxygen monitoring systems are no longer a luxury in the pharmaceutical industry; they are a fundamental part of modern, responsible, and profitable production. The analysis shows that these systems are indispensable for plant safety, protecting against the risk of fire and explosion by actively controlling the inerting process. This approach moves beyond outdated, wasteful methods to a dynamic, data-driven strategy that mitigates risk in real time.

In addition, these systems are critical to ensuring product quality and consistency, preventing unwanted oxidation reactions, and protecting high-value catalysts and raw materials. By providing the data necessary to optimize processes, they also transform inerting from a cost center into a strategic asset that enhances operational efficiency. In a regulatory environment that increasingly demands “intelligent safety systems,” a continuous oxygen monitoring system is the foundational sensor layer that makes such a system possible.

In light of stricter regulations and market demands for unwavering quality, investing in these systems is a strategic imperative. The future of the industry is not just about producing drugs but about doing so safely, efficiently, and with unwavering quality. Technological advancements in oxygen monitoring are a cornerstone of the next generation of intelligent, automated, and intrinsically safer chemical manufacturing.

Ready to get your Continuous Oxygen Monitoring System Solutions? Contact with us please!

FAQs about Why an Oxygen Monitoring System is Essential for Pharmaceutical Chemical Reactors:

Q1: What recent regulatory changes in China demand Oxygen Monitoring Systems in pharmaceutical chemical reactors?

A1: China’s regulatory framework has strengthened over the past 1-2 years. New mandatory standards like GB 45673-2025: General Code for Standardized Safe Production in Hazardous Chemical Enterprises, effective from November 1, 2025, require chemical plants to adopt advanced safety equipment and systems. Under these requirements, facilities dealing with flammable, explosive, or toxic materials must implement real-time monitoring, alarm, and interlock functions for oxygen concentration. Even though GB 19815 is often cited for inert gas protection and online oxygen detection, the stricter enforcement of these kinds of regulations across provinces underscores the necessity of installing a proper oxygen monitoring system.

Q2: How do China’s policy updates affect fine chemical (pharmaceutical) plants with respect to explosion protection?

A2: The updated policies force fine chemical plants to reassess their hazard risk controls. Plants that use volatile organic solvents or combustible solvents must provide inert gas protection. They must also install oxygen monitoring systems that can trigger alarms or interlocks when oxygen levels approach dangerous thresholds. These changes lower allowable risk and require plants to invest in better sensors, tighter process control, and more robust safety protocols across the board.

Q3: Does the new regulation specifically reference online oxygen concentration detection?

A3: Yes. According to the regulatory guidance linked to GB 19815, operations involving flammable/explosive media must set up inert gas protection and online oxygen concentration detection with alarm & interlock systems. These systems must continuously monitor oxygen, especially in closed or semi-closed zones. While some documents are still in draft form or under local implementation, this requirement is becoming standardized across many safety jurisdictions in China.

Q4: What implications do these regulations have for cost and operational efficiency for companies?

A4: On one hand, installing oxygen monitoring systems increases upfront capital and maintenance costs. However, because such systems enable real-time detection, they help avoid costly shutdowns, explosions, regulatory penalties, or product loss. Additionally, better oxygen control improves yield, reduces impurity/defect rates, optimizes inert gas usage, and thus can lead to long-term savings. Essentially, the cost becomes an investment in safer, more consistent, and more compliant production.

Q5: How do pharmaceutical chemical reactors benefit in terms of product quality under the new compliance regime?

A5: With regulations pushing for higher oversight, plants must ensure that oxygen levels are tightly controlled. This prevents oxidation side-reactions, catalyst deactivation, impurity formation, and degradation of APIs (Active Pharmaceutical Ingredients). As a result, products meet stricter purity standards, and batch-to-batch consistency improves. Compliance demands push plants to adopt more reliable monitoring, which directly elevates product quality.

Q6: What technical specifications should an Oxygen Monitoring System meet to comply with Chinese regulations?

A6: Key specifications include:

- Online, continuous measurement of O₂ concentration (not periodic checks).

- Alarm and interlock functionality if oxygen exceeds threshold (often well below explosive limits).

- Compatibility with inert gas protection systems (e.g. nitrogen purging).

- Materials and design suited for harsh environments (e.g. IP-rating, stainless steel 316 for corrosion resistance).

- Sensor technologies (electrochemical or optical) that maintain accuracy in reactor headspace or inlet lines.

These features help ensure compliance with current and upcoming Chinese safety standards.