In a cement-plant environment, selecting the right Continuous Emission Monitoring System (CEMS )supplier is a strategic decision — not just a purchase. The wrong supplier can lead to data gaps, regulatory risks, and unexpected downtime. On the other hand, the right partner delivers reliable instrumentation, strong service support and long-term performance. In essence, your CEMS supplier becomes a cornerstone of operational integrity and emissions management.

Cement manufacturing generates a complex emissions profile: nitrogen oxides (NOx), Sulphur dioxide (SO₂), carbon monoxide (CO), particulate matter (dust) and more. These pollutants impact worker safety, neighborhood air quality and regulatory compliance. A robust CEMS addresses all four dimensions: ensuring safety (via timely detection), ensuring compliance (through accurate reporting), enabling process control (by offering real-time data) and supporting sustainability plans (by tracking emissions trends). Without a properly specified system, those goals become much harder to reach.

In this article, we examine supplier selection through four key lenses: technology fit, lifecycle support, regulatory alignment, and plant-operations context. We focus on the cement-plant context, where harsh conditions, fuel variability and large-scale operations raise the bar for CEMS performance.

What Key Dimensions Should a Continuous Emission Monitoring System Supplier Meet?

Selecting the right supplier for a Continuous Emission Monitoring System (CEMS) in a cement plant isn’t a one-step decision. We can think of it like a pyramid: start at the broad base (“what”), then move to the structure (“how”), and finally to the depth (“why”).

A. What must the supplier guarantee?

First and foremost, you need a supplier who ensures regulatory compliance. Your plant must meet limits on NOx, SO₂, CO, dust and other pollutants. Second, the supplier must cover pollutant species coverage — meaning the analyzers must handle the gases your cement plant produces under all operating modes. Third, availability and reliability: if your CEMS is offline during a stack upset or alternative fuel change, you risk non-compliance or knock-on process issues.

Pick a supplier who ticks these boxes — compliance, coverage, uptime — before you worry about features or cost.

B. How does the supplier match your site and technology needs?

Once the basics are clear, you dive into how the solution fits your plant. Start with technology fit: Does the supplier provide extractive sampling vs in-situ measurement? What analyzer types (NDIR, FTIR, TDLAS, etc.) match your emission profile?

Then consider site conditions. Cement plants pose tough environments: high dust loads, elevated temperatures, variable fuel types (including alternative fuels). Your supplier must demonstrate experience handling those. So, the question is: Not just “does the supplier offer a CEMS?”, but “does their system suit your stack, fuel, and emission mix?”

C. Why does the supplier matter long-term?

At the apex of the pyramid, you evaluate deeper factors that determine long-term success.

–Lifecycle services: installation, commissioning, calibration, maintenance — does the supplier offer those?

–Global/local technical support: if you’re at a remote cement plant, responsiveness, spare parts nearby, remote diagnostics matter a lot.

–System upgrade path & data validity/traceability: emissions monitoring isn’t static. Regulations tighten, fuels change, processes evolve. Choose a supplier whose system allows future upgrades and offers trusted data traceability.

So, the “why” is: your supplier isn’t just a vendor — they are your long-term partner, ensuring your CEMS remains valid, reliable and future-proof.

Together, these three dimensions — what, how, why — form a robust framework. It moves you from basic checkboxes to fit-for-purpose to strategic partnership. If you use this as your map when talking to potential CEMS suppliers for your cement plant, you’ll turn a procurement exercise into a decision that supports compliance, process control and sustainable operations for years to come.

What Makes a Continuous Emission Monitoring System Supplier Stand Out for a Cement Plant?

Cement plants operate under some of the most demanding emission scenarios in industry. They face extreme kiln temperatures, heavy dust loads, and use a mix of fuels including coal, petcoke and alternative fuels. Because of those conditions, emissions don’t just include typical gases like NOx and SO₂—they often include high particulate matter, varying CO and O₂ concentrations, and sometimes heavy metals when waste fuels are co-incinerated. A supplier who understands this profile is more than a vendor—they’re a partner in durability and precision.

Due to the multi-pollutant nature of cement-plant emissions, you must monitor NOx, SO₂, CO, O₂, dust (PM), and occasionally mercury (Hg) and acid gases. Moreover, concentrations can swing rapidly when fuels change or kiln conditions shift, and permits often set very stringent limits with real‐time submission requirements. Therefore, your CEMS supplier must deliver consistent accuracy across a broad dynamic range and in real-time—not just occasionally.

A cement plant stack is no gentle place: flue gas often is hot, highly dusty, abrasive and sometimes corrosive. Because of that, analyzers and sampling systems must be rugged, have long maintenance intervals, withstand harsh conditions and perform under high dust rates. If your supplier offers equipment that isn’t robust enough, you’ll face excessive downtime, calibration burdens and costly maintenance. So don’t just ask “can you supply a CEMS?”—ask “can your system thrive in my cement-plant environment?”

Finally—and perhaps most importantly—the right supplier will show proven experience specifically in the cement sector. They’ve seen fuel switches, clinker kilns, stack fouling, heavy dust environments, permit audits, and data validation exercises. Many general-purpose CEMS suppliers may lack this niche depth. A supplier with a track record in cement plants will understand the operational rhythms, common failure modes and regulatory expectations of this industry. With that history, they don’t just sell equipment—they offer reliability, support and peace of mind.

For a cement plant, choosing a CEMS supplier is not about picking the cheapest unit or flashing specs. It’s about finding a partner who knows your process, knows your pains, and provides systems built for your realities—multi-pollutant stacks, extreme environments, regulatory pressure and long-term reliability. When you priorities these cement-specific considerations, you shift from reactive monitoring to proactive emissions management.

What Technology & Supplier Capabilities Should a Continuous Emission Monitoring System Supplier Offer?

Analyzer Technologies: The Core of Your CEMS

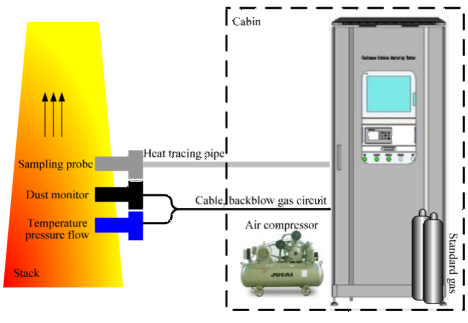

When evaluating a new supplier, you must inspect the heart of the system — the analyzer technologies. Techniques like NDIR (Non-Dispersive Infrared), FTIR (Fourier Transform Infrared) and DOAS-UV (Differential Optical Absorption Spectroscopy – Ultraviolet) offer varying strengths for monitoring gases such as CO, CO₂, NOx, SO₂, HCl and HF. Meanwhile, for O₂ measurement, zirconia and paramagnetic analyzers remain standard choices. In addition, you need to check whether the system is extractive (sample drawn and conditioned before measurement) or in-situ (measuring directly in the duct). Each has implications for maintenance, response time and cost.

Sampling & Conditioning: Handling Harsh Cement-Plant Conditions

Beyond the analyzer itself, the sampling and conditioning system often dictates system uptime and accuracy. In cement plants, your exhaust may carry high dust loads, extreme temperatures, moisture and sometimes corrosives. The system must include filters, heated lines, moisture removal, and robust probe design. For example, a sampling system that fails to remove moisture or dust will degrade optics or block flow—leading to calibration drift and unplanned downtime. Therefore, a good supplier should highlight how they handle those sample-conditioning challenges and offer clear maintenance paths.

Data Acquisition & Reporting: From Raw Data to Actionable Insight

Once the gas is measured, your supplier must deliver the data in a format you can use. That means real-time data output, integration with DCS/SCADA via protocols like Modbus or OPC, trend analytics for process optimization, and reporting that aligns with your cement-plant permits (for NOx, SO₂, CO, O₂, dust, etc). In practice, that means you should ask: Does the CEMS system provide dashboards for operators? Can it export compliance reports automatically? Does it allow process engineers to correlate emissions trends with kiln parameters? A supplier with strong data-capability gives you not just compliance but insight and optimization.

Supplier Service Model: Longevity, Support & Training

Finally, you evaluate the supplier’s service model. Key aspects include:

- Fully managed commissioning and calibration support

- Spare-parts availability and local technical presence

- Training programs for your onsite engineers and operators

- Upgrade paths for analyzer modules when emissions legislation tightens

A supplier who only sells you hardware and walks away is a risk. Your plant needs a partner who stays through the lifecycle. After all, the real cost of your CEMS isn’t just the capex—it’s the maintenance, calibration, downtime and regulatory credibility over years.

When selecting a Continuous Emission Monitoring System supplier, you must look deeply: check the analyzer technologies, sampling & conditioning robustness, data & reporting infrastructure, and the supplier’s service model. These four capability axes determine whether your system will simply comply—or instead become a cornerstone of your plant’s emissions strategy and operational excellence.

Conclusion

In the cement sector, selecting the correct CEMS supplier carries profound implications. It affects compliance with ever-tightening regulations, process insight into kiln and exhaust behavior, cost over the full system lifetime, and risk management for the plant. Without the right partner, you may face downtime, non-compliance, inflated operational costs and missed optimization opportunities. For cement operations, the supplier decision is strategic, not simply transactional.

Here’s what you should do next:

- Map your emission-monitoring needs now — document pollutant species, concentration ranges, fuel mix, stack conditions and regulatory permit demands.

- Engage credible suppliers early — ask for cement-industry references, service models, future-proofing capabilities and total cost models.

- View CEMS not just as a regulatory checkbox, but as an enabler — of sustainability goals, process efficiency and output quality.

By acting now, you position your plant to stay ahead of compliance, drive operational excellence and build a resilient future.

If you want to know more details, contact with us please!

FAQs (Frequently Asked Questions)

Q1. What key questions should a cement plant ask a CEMS (Continuous Emission Monitoring System) supplier?

A: A cement plant should ask about CEMS:

- Which pollutants the system monitors (e.g., NOx, SO₂, CO, O₂, dust, Hg)

- Whether the technology suits high-dust, high-temperature stack conditions

- Service and spare-parts support (local & global)

- Lifetime cost, calibration schedule and data validity/traceability

By clarifying those upfront, you will assess the supplier’s fit more effectively.

Q2. How does technology choice affect CEMS supplier selection in a cement plant?

A: Technology matters because:

- Extractive vs in-situ sampling affects maintenance and reliability

- Analyzer types (NDIR, FTIR, DOAS-UV, zirconia/paramagnetic) vary in robustness, precision and suitability for harsh flue gas

- Site conditions (high dust, moisture, alternative fuels) may favor one technology over another

Choosing a supplier that offers the right technology mix for your situation avoids failures and high cost.

Q3. Why is supplier experience in the cement industry important for CEMS?

A: Cement plants pose unique challenges: heavy dust, variable fuel, high temperatures, multiple pollutants simultaneously. A supplier with proven installations in this environment understands:

- How to design sampling and conditioning systems for such stacks

- Common failure modes and maintenance pitfalls

- Regulatory demands and reporting formats for cement operations

Thus, cement-specific experience reduces risk and increases system uptime.

Q4. What are the cost-related considerations when choosing a CEMS supplier?

A: Key cost factors include:

- CapEx (initial system cost)

- OpEx (calibration, consumables, downtime, maintenance)

- Risk cost (fines, non-compliance events, production loss)

- Upgrade cost (when regulations or fuel mix change)

A strong supplier will offer transparency on lifecycle cost and service model—not just hardware price.

Q5. How can a good CEMS supplier help future-proof a cement plant’s emissions monitoring?

A: A future-ready supplier will:

- Offer modular systems or analyzers that support additional pollutant monitoring (e.g., mercury, HCl)

- Provide data acquisition systems that integrate with DCS/SCADA and regulatory portals

- Have a service network and upgrade path aligned to evolving regulations and fuel switches

This ensures your monitoring system remains relevant and reliable over time.