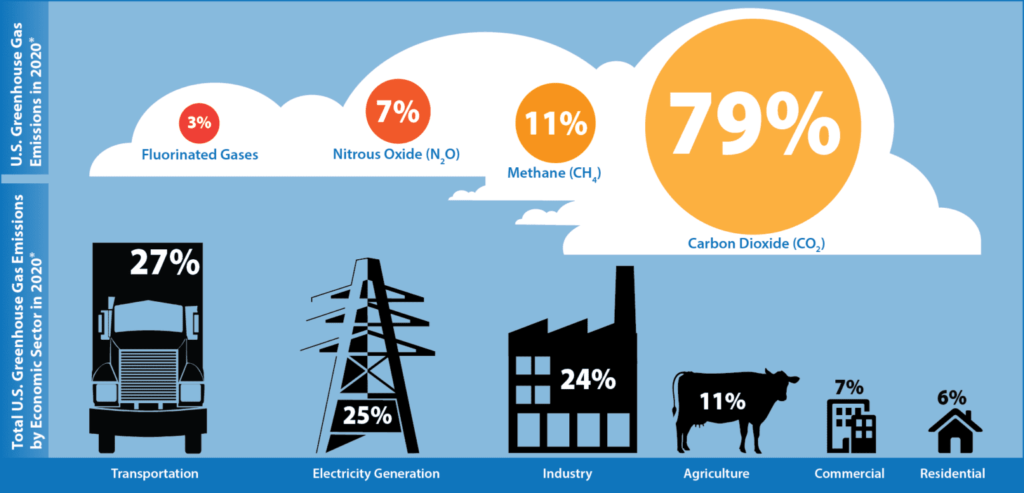

Rapidly tightening emissions regulations, growing pressure from investors and communities, and the intrinsic variability of greenhouse gas sources make reliable measurement more than a nice-to-have — it’s mission-critical. Organizations that rely on poor or intermittent measurements risk noncompliance, wasted mitigation spend, and misguided science. ESEGAS’s greenhouse gas analyzer answer that need with rugged, instrument-grade gas analysis tailored for greenhouse gas monitoring: they combine proven NDIR technology, configurable measurement ranges, and industry-standard outputs so operators can move from guesswork to high-confidence data for CO₂, CH₄ and N₂O.

ESEGAS greenhouse gas analyzers use NDIR technology to measure CO₂, CH₄, CO and N₂O across customizable ranges (e.g., 0–10 ppm to 0–2000 ppm), offering continuous monitoring, calibration support, and industry interfaces for CEMS and environmental monitoring.

Below, we walk through the product identity, core working principle, key specifications, application scenarios, installation & maintenance, data & connectivity, purchasing guidance, and common troubleshooting — each section framed as a clear question and answered with a compact PAS-style lead followed by actionable technical detail.

What is the ESEGAS Greenhouse Gas Analyzer and how does it work?

The problem for many teams is choosing an analyzer that balances sensitivity, robustness, and operational simplicity; the anxiety grows when instruments drift or require complex optics. ESEGAS addresses this by delivering analyzers built on NDIR technology, optimized for greenhouse gases so users gain straightforward, stable detection without excessive maintenance.

- Core principle: Non-Dispersive Infrared (NDIR) sensing — the instrument passes infrared light through a sample cell and measures absorption at gas-specific wavelengths to quantify species such as CO₂, CH₄, CO and N₂O. This method delivers stable, selective measurements for many greenhouse gases.

- Typical gases and ranges (configurable): CO₂, CH₄, CO, N₂O; commercial range options commonly offered include 0–10 ppm, 0–50 ppm, 0–500 ppm, and 0–2000 ppm (other ranges available on request).

- Representative model: ESE-GH-2080 is listed as a greenhouse gas product example on ESEGAS’s product pages (other NDIR and IR series cover methane and CO₂ specifically). Esagas

- Where the instrument shines: relatively simple optical layout, good long-term baseline stability, and compatibility with sample conditioning accessories make NDIR analyzers attractive for both lab and field deployments.

What technical specifications and performance metrics should users expect?

Choosing an analyzer without clear expectations causes costly surprises — users need metrics (detection limit, response time, stability) up front so procurement and experiment design match reality. ESEGAS’s greenhouse gas product line is positioned to provide low detection limits, configurable ranges and practical I/O for integration. Esagas

- Sensitivity & detection limit: NDIR analyzers typically deliver low detection limits adequate for many environmental and process needs; exact detection limits depend on model and configuration. (ESEGAS lists configurable ranges; contact vendor for model-specific LODs.)

- Response time & stability: Designed for continuous monitoring, response times are dominated by sample system volume and pump flow; factory specifications normally include T90 values and long-term zero/span drift figures (request datasheet for the precise values for ESE-GH-2080).

- Accuracy & repeatability: Expect instrument accuracy defined as ±% of reading plus offset; repeatability supports trend and regulatory use when combined with a proper calibration program.

- Calibration: Supports use of calibration gas cylinders for zero/span checks and scheduled calibration routines.

- Environmental limits: Typical operating temperature and humidity ranges are specified per model; sample conditioning (heated lines, filters, coolers) is advised when sampling from hot, wet or particulate-laden streams.

- Interfaces & outputs: Standard industrial outputs such as 4-20mA output and Modbus communication (RS-485 / Modbus TCP/Ethernet) ease integration with PLCs, SCADA, data loggers and CEMS/AQMS systems.

In which application scenarios is the analyzer used?

When organizations lack situational measurements — whether for compliance, science, or operational control — they cannot prioritize emissions reductions effectively. ESEGAS analyzers are built for a spectrum of greenhouse gas applications where reliable concentration data are essential. Esagas

- Environmental monitoring & research: Ambient CO₂/CH₄/N₂O monitoring, greenhouse studies, and flux chambers. Useful where long-term continuous monitoring of atmospheric concentrations is required. Esagas

- Agriculture: Methane emissions monitoring from livestock operations and soil studies, enabling mitigation strategy evaluation.

- Industrial emissions & compliance: Stack or process monitoring to support emission inventories and CEMS verification (CEMS integration) when combined with appropriate dilution or sampling hardware. Esagas

- Leak detection & safety: Field-deployable units can be used to detect methane leaks in pipelines or storage facilities (field-deployable considerations include rugged housing and quick response sample systems).

- Laboratory & R&D: Bench or lab analyzers for controlled experiments and instrument comparisons (NDIR’s simplicity and repeatability make it attractive for many lab setups).

How should the analyzer be installed, how are samples conditioned, and what maintenance is required?

Improper installation or neglected sample conditioning ruins otherwise capable instruments; the solution is a documented sample system, routine maintenance and planned calibration. ESEGAS products are compatible with standard sample conditioning modules (filters, coolers, pumps) and recommend periodic calibration with traceable gases.

- Installation tips: Mount in a ventilated, dust-free cabinet; avoid direct sunlight and large temperature swings. Ensure power and signal wiring follow local electrical codes.

- Sample conditioning: Use particle filters, heated lines or sample gas coolers when sampling hot or humid gases; consider moisture traps for corrosive streams. ESEGAS product pages list compatible gas conditioning accessories. Esagas

- Maintenance schedule: Replace inlet filters on a schedule determined by process conditions, verify zero/span with calibration gas at regular intervals, and inspect optical windows if performance drifts.

- Spare parts & consumables: Keep filter cartridges, sample tubing and a calibration gas cylinder on site for quick turnaround.

- Service & support: For field issues, follow manufacturer troubleshooting then escalate to factory service where necessary.

What are the data handling, connectivity and reporting features?

Data locked in proprietary formats or trapped behind obscure interfaces prevents timely action; modern analyzers should support open protocols and simple export. ESEGAS devices provide the typical industrial interfaces required to feed analytics, reporting and compliance systems.

- Protocols & outputs: Expect Modbus communication (RS-485 or TCP), 4-20mA output channels for each measured species or an index channel, and Ethernet for remote data access.

- Data logging: Onboard logging or external data logger compatibility; export formats commonly include CSV or direct SCADA/DB feeds.

- Remote monitoring & alarms: Ethernet/Modbus integration enables remote alarm thresholds, trend dashboards, and SCADA visualization.

- Integration with CEMS/AQMS: Use standard outputs and proper sampling/correction factors to feed regulatory systems and reporting pipelines (CEMS integration considerations).

- Reporting: Generate routine reports (daily, monthly) from logged data and validate against calibration records for audit trails.

What should buyers consider when choosing an ESEGAS analyzer and how does it compare to alternatives?

Selecting the wrong range or forgetting integration details causes rework and extra cost; focus on the measurement target, detection limit, sample environment, and required interfaces. ESEGAS positions its greenhouse gas analyzers as configurable, industrially oriented instruments suited for many common monitoring roles.

- Specify measurement targets: Choose ranges and models that match expected concentration windows (ambient vs. process emissions). For low ambient methane work, prioritize models and setups with low detection limitspecifications.

- Configuration choices: Field vs. lab enclosure, heated sample lines, and accessory choices (sample coolers, pumps, filters) determine usability in harsh environments.

- Integration: Confirm required Modbus communication and 4-20mA output needs up front to avoid later retrofits. Esagas

- Cost vs. service: Consider lifetime service, availability of spare parts, and on-site calibration options when comparing to competitors. ESEGAS emphasizes ODM/OEM manufacturing and accessory compatibility across its analyzer lines. Esagas

Common FAQs and troubleshooting steps

Unclear procedures for routine checks or quick troubleshooting lead to unnecessary downtime. Simple verification steps and a documented escalation path usually solve most on-site anomalies. Esagas

- If readings drift: perform zero/span check with certified calibration gas; inspect filters and sample lines for blockages or moisture.

- If communications fail: verify network wiring, Modbus addresses/baud rate, and power supply; swap to RS-485 or Ethernet diagnostics as required.

- If instrument alarm triggers: consult log for last good reading, run an immediate span check, and isolate sample source to test for transient contamination.

- Warranty & support: ESEGAS provides contact and service channels on its site; procure spare consumables and a calibration gas bottle to reduce MTTR.

Conclusion

Accurate greenhouse gas measurement is foundational to compliance, operations and science. ESEGAS’s greenhouse gas analyzers — built around NDIR technology and offered with configurable ranges and standard industrial I/O — provide a balanced solution for methane emissions monitoring, ambient CO₂ tracking, and N₂O detection across lab and field scenarios. For teams that need continuous monitoring, field-ready performance, and straightforward CEMS integration, evaluate the ESE-GH family and match the model to your detection limit, connectivity and sample conditioning needs. For demos, datasheets, model-specific LODs and accessory options, contact ESEGAS via their product page.

If you have questions, please contact us directly!