When you buy a continuous process gas analyzer from a supplier like ESEGAS, customer support should do more than merely patch problems. It should protect your operations ensure measurement integrity, and reduce long-term cost. In industries where safety, emissions, and process quality matter, you must expect support at every stage—from specification and installation to maintenance and upgrades.

Before we dive into specific features, it helps to see just how much is at stake when support from a continuous process gas analyzer supplier falls short

Why Does Support from a Continuous Process Gas Analyzer Supplier Matter So Much?

Continuous process gas analyzers are not “set and forget” devices. If the analyzer fails—even briefly—you risk:

- Regulatory non-compliance (missing emissions limits, failed audits)

- Safety incidents (undetected leaks, toxic or flammable gas buildup)

- Process inefficiencies (wrong gas mix, wasted fuel or catalysts)

- Higher lifecycle cost (many small failures often cost more than a full life maintenance contract)

Therefore, your supplier’s support is a core part of the instrument’s value. Without strong support, even a high-precision analyzer like ESEGAS’s IR-GAS-600 or UV-GAS-500 may deliver sub-standard performance.

Now that we understand why support matters, let’s examine the concrete features you should look for in a supplier like ESEGAS.

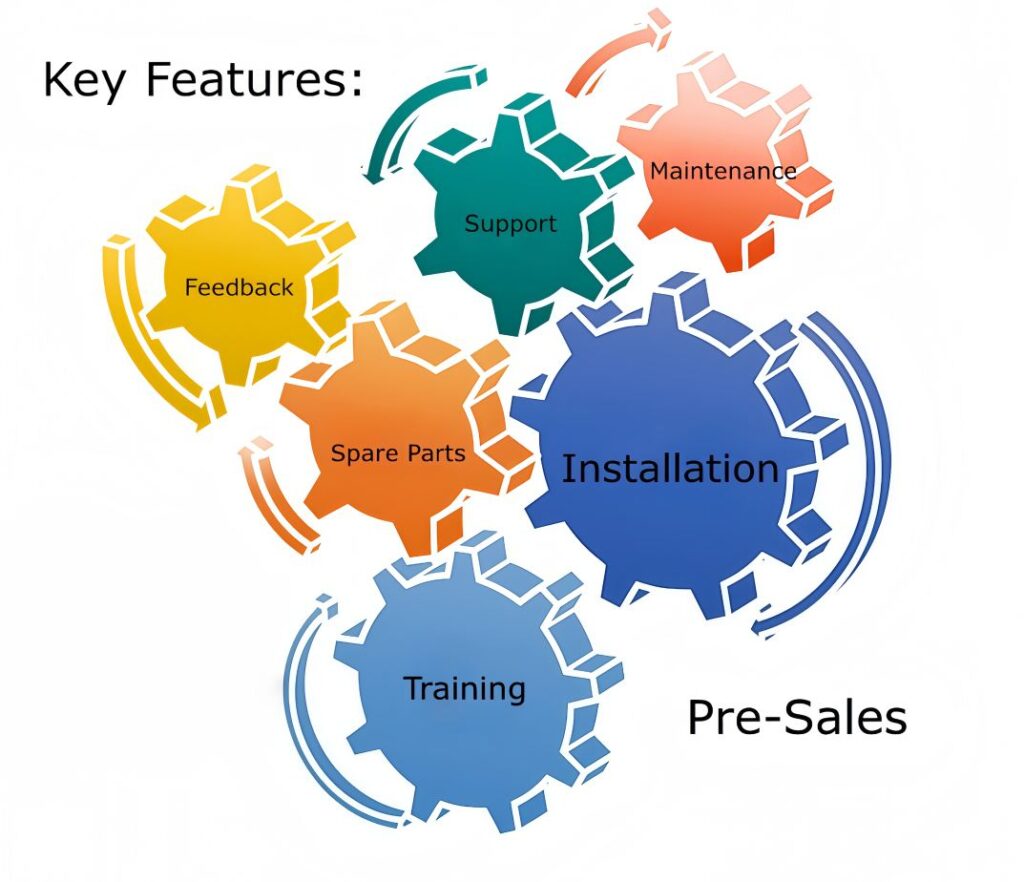

What Key Features Define Good Support from a Continuous Process Gas Analyzer Supplier?

Here are the key support features you should demand. Use them to evaluate ESEGAS and any alternative.

- Pre-Sales & Specification Advisory

- Gas matrix assessment: temperature, pressure, humidity, interferents.

- Technology matching: choosing between NDIR, TDL, UV, FTIR etc. based on gas types like CO, CO₂, CH₄, H₂ etc. (ESEGAS supports many of these in their process gas monitoring system).

- Site condition evaluation: ambient, sample conditioning, safety zones.

- Transparent budgeting: cost of analyzer plus installation, calibration, spares, training.

- Installation & Commissioning

- Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT) with documented results.

- Supervised installation so components like sample lines, filters, detectors are properly set.

- Zero/span calibration, response time tests, and performance verification under real process gas.

- Training & Documentation

- Clear, up-to-date manuals with: theory of operation, maintenance schedules, troubleshooting.

- Hands-on training for operators and maintenance personnel.

- Access to digital media: videos, application notes, updates.

- Spare Parts & Calibration

- Local stock of consumables (filters, sensors, lamps) to minimize lead time.

- Certified calibration gases or reference materials.

- Defined schedule for calibration and drift checks.

- Maintenance & Field Support

- Hotline or support desk (ideally staffed with gas analysis experts).

- Remote diagnostics (if possible) and on-site service when needed.

- Preventive maintenance contracts to avoid surprises.

- Upgrades, Regulatory & Software Support

- Firmware/software updates for bug fixes, new features, and cybersecurity.

- Support to meet changing environmental or safety regulations.

- Option to enhance analyzer performance (e.g. extra gas channels, better detection limits) when needed.

- Feedback & Continuous Improvement

- Structured feedback mechanism: you should be able to report field issues, share usage data.

- Supplier should use that feedback to improve product reliability (MTBF, drift, etc.).

- Transparency about reliability: failure rates, support turnaround times, etc.

With the ideal support profile in mind, it’s time to see how ESEGAS stacks up — and where to probe deeper before you commit.

How Does ESEGAS Measure Up as a Continuous Process Gas Analyzer Supplier and What Should You Investigate Further?

ESEGAS offers a strong foundation:

- Their IR-GAS-600 analyzer can handle multiple gases (CO, CO₂, CH₄, O₂, H₂) with high stability.

- They produce a broad portfolio: UV gas analyzers, TDL systems, NDIR, etc. This breadth helps match technology to need.

But there are areas where you should ask probing questions:

- Commissioning & Validation Records: Does ESEGAS provide SAT or FAT reports with data under your actual process gas composition?

- Spare Parts Lead Time: Where are key components stocked? Are filters, sensors, calibration gases available in your region or must they come from overseas?

- Service Engineer Access: Can they send someone locally? How fast? Is there remote diagnostic support for urgent issues?

- Regulatory Traceability: Will documentation satisfy your emission authority or auditor? Are calibration gases traceable to recognized labs?

- Upgrade Flexibility: Can you add more gas measuring channels later? Upgrade detection limits without replacing the entire unit?

A checklist you can use right now

| Feature | Question to Ask Supplier / ESEGAS | Why This Matters |

| Gas matrix expert available pre-order | “Can you analyze our specific process gas including expected interferents?” | Ensures proper analyzer technology and avoids surprises. |

| Installation / acceptance testing | “Do you provide documented FAT/SAT with our gas composition and conditions?” | Validates performance from day one. |

| Spare parts & consumables lead time | “What is your local stock and how fast can parts be delivered?” | Minimizes downtime. |

| Calibration support | “Do you supply traceable gases? How often do you recommend calibration?” | Maintains measurement accuracy and regulatory compliance. |

| Field service & remote support | “Is there 24/7 hotline? Can you do remote diagnostics?” | Critical when something fails during production. |

| Regulatory & software updates | “Do you release firmware updates? How do you handle changes in emission regulations?” | Avoids obsolescence and non-compliance. |

| Reliability metrics & feedback channels | “What’s your MTBF? Can I talk to clients in similar use? How do you incorporate feedback?” | Gives insight into the supplier’s credibility and learning culture. |

Beyond the formal promises and paperwork, there are underlying responsibilities that separate good suppliers from great ones.

What Deeper Responsibilities Should a Continuous Process Gas Analyzer Supplier Take beyond the Contract?

Support isn’t just about reacting. It’s about partnership. When a supplier behaves as a partner, you see:

- They anticipate your future needs (regulation changes, plant expansions).

- They value trust: you feel safe to speak up about field issues, not just problems but inefficiencies.

- They build accountability: they publish reliability data, respond swiftly, commit to timetables.

Also, in a world moving toward stricter environmental controls and digitalization, support becomes a differentiator. An analyzer isn’t just hardware. It’s part of a data ecosystem. Suppliers that integrate remote diagnostics, predictive maintenance, and regulatory alerts help you sleep better at night.

As we wrap up, here are the expectations and demands you should insist upon — so you get both performance and peace of mind.

Conclusion

When you engage a continuous process gas analyzer supplier like ESEGAS, expect more than a device. Expect a full lifecycle support system:

- Expert specification advice up front.

- Rigorous commissioning.

- Well-stocked spare parts.

- Skilled maintenance and field support.

- Regular upgrades and compliance help.

Don’t settle. Ask questions. Use the checklist. Insist on documented performance. In doing so, you protect your plant, reduce costs, and ensure environmental and safety integrity. When support becomes part of the promise, you get true value—not just a product.

If you have any questions about gas analysis, contact with us please!

FAQs about a Continuous Process Gas Analyzer Supplier:

- What factors should I evaluate when choosing a continuous process gas analyzer supplier?

When choosing a supplier, check:

- Gas matrix matching (type of gas, concentration, interferences, moisture).

- Technology fit (NDIR, UV, TDL, etc.).

- Spare parts & consumables availability (local vs overseas).

- Maintenance & calibration policies (frequency, certified gases).

- Support contracts and response times.

- Regulatory compliance and documentation.

These aspects reduce risk, cut total cost of ownership, and ensure safe, accurate operation.

- How do I verify a continuous process gas analyzer supplier’s support for installation and commissioning?

You should ask the supplier for:

- Installation supervision or commissioning checklist.

- Calibration of zero/span and performance verification in situ.

- Documentation of response time, alignment, signal stability etc.

These ensure the system meets your specs once operational.

- What spare parts and consumables availability should I expect from a continuous process gas analyzer supplier?

A good supplier should provide:

- A list of high-wear consumables (filters, pumps, sensors) and recommended spare stock.

- Local or regional stock to cut lead times.

- OEM authorized parts.

- Kits or packages for emergency replacements.

This helps you avoid long downtimes and high expedited shipping costs.

- How often should calibration and maintenance happen and does the supplier provide certified calibration gases?

- Calibration: typically once a year under normal use; more often (e.g. every 6 months or quarterly) in harsh or high-use environments.

- Maintenance: preventive maintenance every 3-6 months; more frequent checks for filters, sample lines etc.

- Supplier does not always provide certified calibration gases, and it depends on the real conditions of customers.

- How does a continuous process gas analyzer supplier stay compliant with changing regulations and environmental standards?

Look for these evidence points:

- Supplier monitors legislative changes (local, national, international) and updates firmware/software accordingly.

- They offer regulatory compliance documentation (certifications, test reports).

- They support periodic audits through traceable calibration and performance reports.

- They assist clients in adapting when standards tighten, e.g., offering lower detection limits or additional gas channels.

This helps your plant stay legal and avoid fines.

- What cost of ownership elements (beyond purchase price) should I discuss with a continuous process gas analyzer supplier?

Key elements to include in your calculation:

- Cost of consumables (filters, pumps, calibration gases).

- Spare parts inventory and shipping costs.

- Calibration and maintenance labor.

- Downtime costs (how quickly supplier can respond).

- Upgrade costs for software/hardware to meet regulatory changes.

- Energy/power consumption, sample conditioning and gas handling costs.

Putting these into your budget gives you a more accurate picture of lifetime cost, not just the sticker price.