A sample gas conditioning system plays a crucial role in any extractive Continuous Emissions Monitoring System (CEMS). After stack gas leaves an industrial source, it often contains moisture, particulates, and corrosive components that can distort analyzer readings or damage sensitive sensors. This conditioning stage removes water vapor and solids before the gas reaches analyzers, ensuring the measurement reflects the true pollutant levels without interference. Without this preparation, analyzers may deliver inaccurate readings and require frequent repairs, raising maintenance cost and risking regulatory non-compliance. In essence, conditioning protects the integrity of emissions data and extends analyzer service life.

In the sections that follow, you will gain a clear and practical understanding of sample gas conditioning systems. First, you’ll see a precise definition of what the sample gas conditioning system are and why it is vital for CEMS performance. Next, we will explore their key components and how they work together to prepare gas samples for analysis. By the end, you will have both conceptual insight and actionable knowledge to evaluate or optimize a sample gas conditioning setup for emissions monitoring.

What Is a Sample Gas Conditioning System in CEMS?

To understand how CEMS delivers reliable data, we need to start with the sample gas conditioning system itself. In an extractive CEMS setup, this system prepares raw flue or stack gas before analysis. The gas leaving the process is hot, wet, and often dirty. Moisture, dust, and acidic compounds can easily distort measurements or damage analyzers. The conditioning system removes these unwanted elements and stabilizes the gas state. As a result, analyzers receive a clean, dry, and controlled sample. Simply put, analyzers only measure what reaches them, and conditioning ensures that measurement reflects reality, not interference.

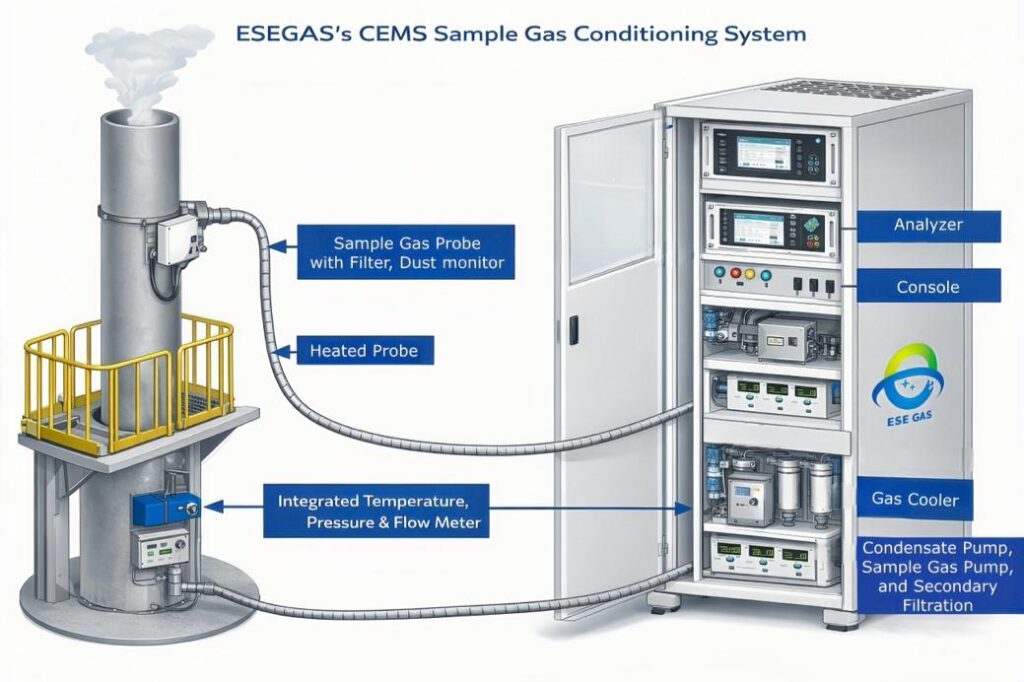

Once the gas is defined, the next step is understanding how the system is built. A typical sample gas conditioning system combines several functional components, arranged along the gas flow path.

- Sample Probe and Filter extract gas directly from the process. A sintered filter blocks dust, while membranes stop liquid ingress.

- Heated Sample Line transfers gas to the conditioning unit while staying above the dew point, preventing condensation and gas loss.

- Sample Gas Cooler reduces gas temperature to condense and remove water vapor, often using Peltier or refrigeration technology.

- Condensate Pump or Trap continuously drains collected moisture, usually via a peristaltic pump.

- Secondary Filtration / Fine Conditioning capture remaining particulates to protect analyzers.

- Sample Gas Pump pulls the gas steadily through the system.

- Temperature, Pressure, and Flow Meters monitor and stabilize delivery conditions.

These elements usually sit inside a sealed cabinet or panel for safety and reliability.

Ultimately, it is important to separate two often-confused functions. Sampling and conditioning serve different purposes in CEMS. Sampling simply captures a portion of the process gas from the stack or duct. Conditioning, however, transforms that raw sample into a stable and measurable form. It controls temperature, removes moisture, filters solids, and ensures consistent flow. Without conditioning, sampling alone delivers unstable and misleading data. Together, sampling and conditioning form a complete measurement chain. One collects the gas, and the other makes the data trustworthy.

Why Does a Sample Gas Conditioning System Matter for CEMS Performance?

In practice, gas analyzers face harsh and unstable conditions. Stack gas temperature can swing quickly, and moisture levels often change with load or fuel type. These shifts directly affect measurement signals. Water vapor can dilute gas concentrations, while condensation alters optical paths or reaction chemistry. Over time, heat and moisture also shorten sensor life. A well-designed sample gas conditioning system solves this problem. It holds the sample above a controlled dew point and delivers a stable gas matrix to the analyzer. As a result, readings stay consistent from hour to hour and day to day. Repeatable data builds confidence in every reported value.

Beyond accuracy, equipment protection is another key concern. When hot-wet gas enters an analyzer, acid aerosols and fine particles attack internal components. Optical windows foul, sensors corrode, and pumps wear faster. This damage leads to frequent shutdowns and unplanned service. By contrast, effective sample gas conditioning removes moisture, acids, and solids before they reach the analyzer. Clean gas reduces stress on analyzer benches and keeps internal surfaces intact. Over time, operators see longer maintenance intervals, fewer spare parts, and higher system uptime. In simple terms, conditioning keeps analyzers working instead of sitting offline.

Importantly, sample gas conditioning directly affects regulatory compliance. Environmental regulations demand continuous, valid data within defined quality limits. Moisture interference or unstable signals often trigger “non-results” or invalid readings. These gaps can lead to reporting penalties or failed audits. A reliable sample gas conditioning system minimizes such risks. It ensures the analyzer receives a clean and controlled sample that meets measurement specifications. With stable inputs, reported values remain defensible and audit-ready. For operators, this means fewer compliance surprises and greater confidence in every emissions report.

How Does a Sample Gas Conditioning System Work in CEMS?

1. Hot-Wet Extraction: Start With the Source

The first step in the conditioning process begins right at the stack. A heated sample probe draws the gas out and immediately filters out large solids to protect downstream components. Keeping the probe and initial line above the dew point prevents moisture from condensing early, which could trap water-soluble gases or cause corrosion. In this stage, the goal is to maintain the gas as close to its original stack state as possible while removing the worst particulates that could clog or damage the system later.

2. Thermal Stabilization: Hold Temperature and Flow Steady

After extraction, the hot sample travels through a heated line where its temperature stays above the critical dew point. This prevents early condensation and ensures that heat-sensitive analytes remain in the correct phase. Next, a sample pump draws the gas at a consistent flow rate. This stable temperature and flow help downstream components work predictably and avoid spikes or dips that could skew measurements. In essence, thermal stabilization creates a controlled “baseline” for conditioning.

3. Moisture Reduction: Choose Drying Strategy

Moisture removal is the heart of conditioning, and systems use two main strategies. Traditional cool-dry systems use thermoelectric coolers to lower gas temperature and condense water for removal. These are effective for many applications but carry a risk of losing water-soluble analytes. By contrast, Nafion-based dryers pull water out in the vapor phase through a selective membrane, preventing condensate and protecting analytes such as SO₂ and NOx. Both approaches aim to lower dew point and deliver a dry sample, but the Nafion approach often yields better accuracy and lower maintenance in challenging conditions.

4. Final Conditioning: Polishing Before Analysis

Once moisture is reduced, the sample undergoes final conditioning. Fine filters and scrubbers remove any remaining particulates and trace liquids. This “polishing” step guarantees that what reaches the analyzers is stable, clean, and representative of true stack conditions. Only after this stage does the conditioned gas enter the analyzer cabinet, ready for precise measurements with minimal interference.

This step-by-step flow—from hot-wet extraction to final polishing—ensures that CEMS analyzers receive a clean, dry, and stable gas sample. That’s how a sample gas conditioning system turns a raw, harsh emission stream into data you can trust.

Conclusion

In summary, a sample gas conditioning system plays a central role in delivering accurate, consistent emissions data. Without it, moisture, particulates, or acidic compounds can distort analyzer readings and shorten instrument life. Conditioning makes the sample analyzable by removing unwanted components and stabilizing temperature and flow before the gas hits sensitive sensors. This leads not only to reliable measurement accuracy but also to enhanced operational uptime and regulatory compliance. In short, conditioning safeguards both data quality and equipment health in any extractive CEMS setup.

Now that you understand how conditioning impacts accuracy, uptime, and compliance, the next action is to assess your own system design against real process needs. Start by checking stack conditions such as temperature, moisture content, and particulate load. Then verify that your conditioning setup — including sampling probes, heated lines, moisture reduction strategy, and flow control — matches those conditions and the pollutants you must monitor. Also review maintenance practices and calibration routines to ensure long-term stability. Real-world systems that align with actual operating environments deliver better performance and fewer surprises over time.

In conclusion, if you need a robust, integrated solution, consider ESEGAS Sample Gas Conditioning System. By exploring such engineered solutions, you can find designs that reduce manual interventions and enhance measurement reliability — all while fitting seamlessly into your existing CEMS architecture.

FAQs:

1. What is a sample gas conditioning system in CEMS?

A sample gas conditioning system is a part of an extractive Continuous Emissions Monitoring System (CEMS) that prepares the raw flue or stack gas before it reaches analyzers. It removes moisture, particulates, and other interfering components so analyzers can measure pollutant concentrations reliably without damage or signal distortion.

2. Why does CEMS require a sample gas conditioning system?

CEMS analyzers need clean, stable gas to deliver accurate results. Raw stack gas is often hot, humid, and full of solids. Without conditioning, moisture and particles can skew readings and wear down sensitive measurement sensors. Conditioning ensures stable temperature, reduced moisture, and filtered gas for accurate, repeatable measurements.

3. How does a sample gas conditioning system remove moisture?

Moisture removal in conditioning systems typically happens via two methods:

- Cool-dry systems (gas cooler) condense water by lowering gas temperature, then drain it.

- Nafion membrane dryers remove moisture as vapor without condensing it — preserving water-soluble analytes. Both strategies aim to lower dew point and protect analyzers.

4. What are the main components of a CEMS sample gas conditioning system?

Key parts of sample gas conditioning system include a heated probe and filter to extract and clean gas, a heated transport line to prevent condensation, moisture removal units (coolers or membrane dryers), condensate traps/pumps, fine particulate filters, a sample pump, and monitoring instruments for flow, temperature, and pressure. These components usually fit into a protective cabinet or panel

5. What is the difference between sampling and conditioning in CEMS?

Sampling is simply pulling a portion of stack gas from the source. Conditioning is what happens next: stabilizing the sample by controlling temperature, removing water and solids, and preparing it so that analyzers can perform accurate measurements. Both are essential but serve different purposes.

6. What common challenges affect sample gas conditioning performance?

Typical issues include filter clogging, moisture breakthrough, inconsistent temperature control, and condensate buildup. These problems can lead to signal drift, analyzer fouling, and higher maintenance costs. Regular inspection and correct system design help prevent such failures.