Many furnaces, kilns, and boilers still “fly blind” on oxygen, running with guesswork excess air. That wastes fuel, elevates NOx and CO, causes unstable flames, and risks product non-uniformity—costs that compound every hour.A Zirconia Oxygen Analyzer gives real-time O₂ right in the hot flue, enabling tight air-to-fuel control, safer operation, and measurable savings.

A Zirconia Oxygen Analyzer is an in-situ gas analyzer that uses a heated zirconium dioxide (ZrO₂) solid-electrolyte sensor to measure oxygen directly in high-temperature combustion gas. It provides fast response, wide measurement range (from ppm to %O₂), and robust performance in furnaces, boilers, kilns, and incinerators for combustion optimization and compliance.

Below, we move from the “what” to the “how”: core operating principle, where it excels, how it compares with other O₂ technologies, which specifications matter in the field, installation/maintenance do’s and don’ts, and the typical efficiency and emissions gains you can expect.

What is a Zirconia Oxygen Analyzer?

Sampling systems struggle in hot, dusty, or corrosive stacks. Long sample lines cool and contaminate gas, delaying readings.An in-situ Zirconia Oxygen Analyzer places the sensor tip directly into the flue, eliminating lag and sample conditioning errors.

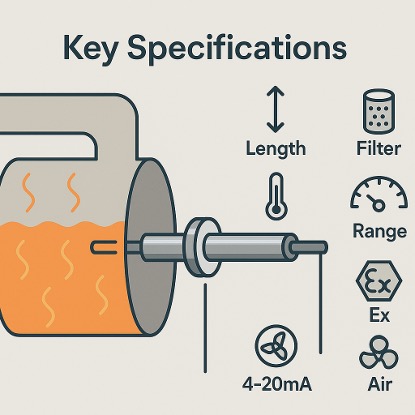

- Architecture. A high-temperature zirconia probe with an integral heater and reference air feeds a transmitter (local or remote) that outputs 4–20 mA/fieldbus.

- Measurement range & speed. Typical coverage spans ppm levels up to 21% O₂, with seconds-level T90response for stable closed-loop excess-air control.

- Rugged by design. Ceramic/metallic protection tubes, sintered filters, and anti-soot geometries tolerate >700–800 °C gas streams and high dust loading.

From here onward, we will naturally use the semantic keyword: Zirconia Oxygen Analyzer.

How does a zirconia cell measure oxygen at high temperature?

Without accurate O₂, operators over-air to “be safe,” burning fuel and raising NOx. Slow or drifting signals push plants to manual tweaks. The Zirconia Oxygen Analyzer converts oxygen partial-pressure differences into an electrical signal with exceptional immediacy.

- Electrochemistry. Heated ZrO₂ conducts O²⁻ ions. The difference between process-gas O₂ and reference air generates a Nernst potential (or a pump current in some designs) proportional to O₂ concentration.

- Stability & drift. Closed-loop heater control holds the sensing cell at temperature, limiting drift; periodic zero/span checks validate performance in critical services.

- Speed. Direct insertion avoids long transport delays, supporting tight PID control of air dampers and VFD fans.

Where is it used across industry? Top application scenarios

Steel, glass, cement, power, and waste-to-energy face fuel costs and emissions caps. Small O₂ errors (e.g., 1–2 vol% too high) silently erode margins.Deploying a Zirconia Oxygen Analyzer at the right flue location unlocks quick wins.

- Industrial boilers & HRSG duct burners: Trim excess air to the optimal band; stabilize CO and improve heat-rate.

- Reheating/annealing/heat-treat furnaces: Protect product quality while minimizing scale and fuel.

- Cement and lime kilns: Manage primary/secondary air for fuel mix changes and alternative fuels.

- Glass furnaces & float lines: Balance O₂ for crown life and pull-rate efficiency.

- Municipal/medical waste incinerators & biomass units: Maintain destruction efficiency and support CEMS validation windows.

- Refining & petrochemical heaters: Improve bridgewall temperature uniformity and coil life with tighter air-to-fuel ratios.

Zirconia vs. other O₂ technologies: which fits your need?

Mismatched technology leads to maintenance headaches and bad data. Over-specified analyzers inflate capex; under-specified ones fail in months.Use this quick comparison to see where a Zirconia Oxygen Analyzer shines.

Detailed answer (comparison).

| Attribute | Zirconia Oxygen Analyzer (In-situ) | Paramagnetic (Extractive) | Electrochemical (Galvanic) | TDLAS O₂ (Laser) |

| Best use | Hot flue, combustion control | Clean, conditioned samples | Portable/spot checks, clean gas | Clean, fast extractive paths |

| Temp tolerance at sensor | Very high (probe in hot gas) | Low—needs conditioning | Low—sample only | Moderate—probe/paths external |

| Response time | Seconds | Tens of seconds (w/ lines) | Seconds to tens | Seconds |

| Maintenance | Low—soot/ash cleaning | Sample system intensive | Sensor replacement | Alignment/optics care |

| Cross-sensitivities | Robust; watch sulfur/lead poisons | Susceptible to magnetic noise | Affected by contaminants | Window fouling, optical noise |

| Cost vs. performance | High ROI in combustion | Medium | Low to medium | Medium to high |

Takeaway. For high-temperature combustion, an in-situ Zirconia Oxygen Analyzer is usually the most responsive, practical choice.

Which specifications actually matter in the field?

Focusing only on “accuracy % of reading” ignores installation realities. The wrong probe length or materials can halve sensor life.Match the Zirconia Oxygen Analyzer to your process conditions.

- Process temperature & materials. Verify max gas temperature, thermal shock resistance, and whether you need ceramic vs. alloy protection tubes.

- Probe length & insertion depth. Reach well into the representative flue core; avoid walls, eddies, and stratification.

- Filtration & anti-fouling. Sintered caps or cyclone tips reduce ash deposition; plan for soot-blowing or occasional cleaning.

- Range & resolution. Ensure ppm capability for low-O₂ runs and %O₂ for start-ups and air-leak checks.

- Outputs & comms. 4–20 mA with HART/Modbus/Profibus plus relays for alarms; check DCS/PLC compatibility.

- Hazardous area & safety. ATEX/IECEx/FM approvals; purge/isolations where needed.

- Utilities. Reference air supply (instrument air or built-in pump), optional calibration gas ports.

How should you install and maintain an in-situ probe?

A great analyzer installed in the wrong place reads the wrong gas. That drives bad control moves and needless maintenance.Treat the Zirconia Oxygen Analyzer like a process instrument, not just a “stack gadget.”

- Location. Choose a fully mixed zone downstream of the last air injection, upstream of dilution air ingress; avoid condensate regions.

- Orientation. Slight downward tilt prevents particulate pooling and thermal shock from drips.

- Start-up/shutdown. Warm the probe before exposure; cool under purge to reduce stress.

- Calibration. Implement routine zero/span checks (ambient or bottled gases). Log drift to schedule proactive service.

- Cleaning. Set intervals based on ash/soot rate; many plants pair with compressed-air purge to extend intervals.

- Troubleshooting cheat-sheet. Slow response → fouled filter; unexpected low O₂ → reference air loss; noisy signal → poor grounding or unstable flow.

What efficiency and emissions gains are realistic?

Projects stall without quantified benefits. “It should save fuel” isn’t enough for a capex case.Use conservative planning numbers from Zirconia Oxygen Analyzer deployments.

Detailed answer (typical ranges, your results may vary).

- Fuel savings: Reducing excess air by 1–2 vol% often yields 1–3% fuel savings on natural-gas-fired units; higher on oil/solid fuels when CO is constrained.

- Emissions: Tighter O₂ control stabilizes CO and can lower NOx by enabling lower average air without flirting with incomplete combustion.

- Stability & throughput: Improved flame stability reduces trips and widens operating window, supporting higher, steadier loads.

- Payback: Many sites see months-to-low-year paybacks when integrated in closed-loop air-trim with dampers/VFDs.

How does it integrate with CEMS and safety systems?

Data islands complicate compliance and root-cause analysis. Manual logs are error-prone.Network the Zirconia Oxygen Analyzer cleanly.

- CEMS/EMS integration. Map O₂ to your emissions calculations (e.g., O₂-corrected ppm). Ensure time-alignment with flow and pollutant analyzers.

- Controls. Use hard-wired 4–20 mA for the PID loop; keep digital comms for diagnostics.

- Alarms & interlocks. High/low O₂ alarms for flame safety envelopes; voting/dual-probe strategies on critical furnaces.

- Data integrity. Tag calibration events, store diagnostics (cell impedance/heater power) for audit trails and predictive maintenance.

Conclusion

The Zirconia Oxygen Analyzer is the workhorse for high-temperature combustion monitoring: fast, direct, and rugged. By selecting the right probe materials and insertion depth, integrating with your DCS/PLC and CEMS, and maintaining a disciplined calibration/cleaning routine, you unlock lower fuel burn, steadier flames, and cleaner stacks—benefits that typically pay for themselves quickly in demanding industrial environments.