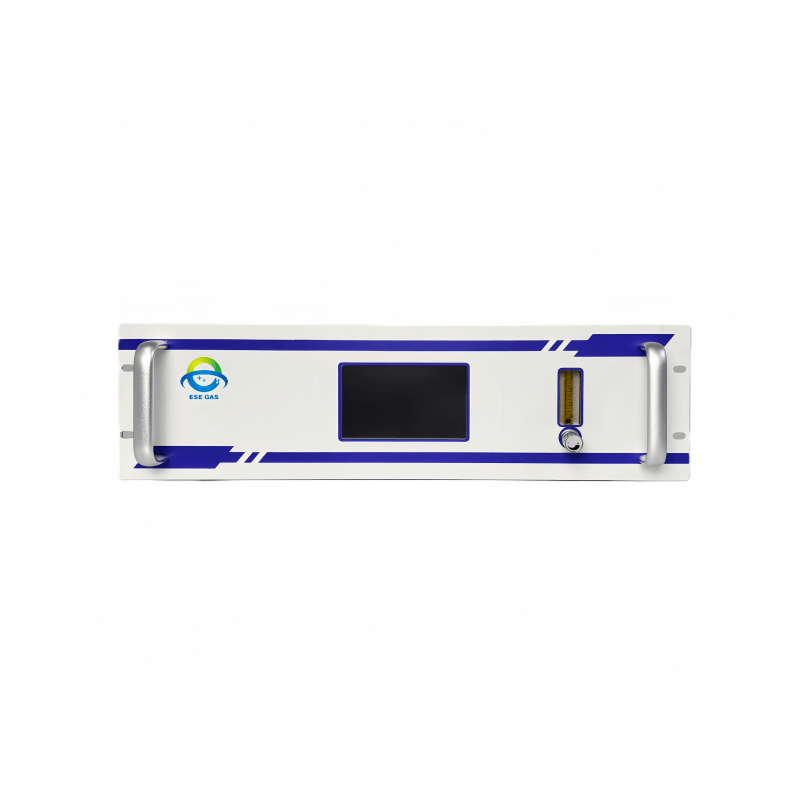

Struggling with invisible methane risks, tightening compliance, and unreliable readings? Those pressures can snowball—false alarms, missed leaks, and unplanned downtime all cost real money and reputation. Modern infrared instruments, the Methane (CH₄) Analyzer make methane measurable, manageable, and auditable. That’s exactly where ESEGAS’s solutions step in, bringing trace-level accuracy and rugged, application-ready design to your process, environment, and R&D needs.

A methane analyzer is an instrument that quantifies methane concentration in a gas stream, typically using infrared absorption (NDIR or IR) to convert selective CH₄ absorption at specific wavelengths into a calibrated reading. It’s used for process control, emissions monitoring, leak detection, and research where reliable CH₄ data is required.

You’ve got the short answer—now let’s turn it into decisions. Below is a practical, industry-focused guide to how a methane analyzer works, why ESEGAS’s configuration matters, where it’s used, and how to select, integrate, and maintain it for the best lifecycle ROI.

What exactly is a methane analyzer and how does it work?

Problem: drifting readings and cross-interference can torpedo trust in your CH₄ numbers. Agitation: humidity, dust, and co-present gases often skew baselines. Solution: non-dispersive infrared (NDIR) selectively measures methane’s unique absorption bands, paired with conditioning and compensation to keep signals stable.

- Principle: An IR source passes through a gas cell; CH₄ absorbs at characteristic wavelengths. The reduction in transmitted IR is proportional to concentration and is converted to ppm/ppb with calibration.

- Outputs & control: Industrial analyzers commonly offer analog (e.g., 4–20 mA), digital (e.g., Modbus), and alarm relays for PLC/DCS integration and interlocks. (Industry standard practice inferred from vendor specs.)

- Why IR/NDIR: Simple optical path, continuous measurement, and robust selectivity for hydrocarbons such as methane; widely adopted in process and emissions work.

Why choose ESEGAS’s Methane(CH4) Analyzer?

Problem: general-purpose sensors struggle in wet, corrosive, or mixed-gas streams. Agitation: that leads to frequent maintenance and questionable data. Solution: ESEGAS’s IR-GAS-600 series Methane(CH4) Analyzer combines trace-level sensitivity with configurations tailored to process gas, emissions, and specialty use cases.

- Trace detection & stability: Product literature highlights high accuracy at low concentrations (down to trace/ppb levels) for demanding applications.

- Application breadth: CH₄ single-gas or multi-component builds (e.g., CO/CO₂/O₂/H₂ + CH₄) under the IR-GAS-600 platform simplify footprint and integration.

- Deployment-ready: Configurable for continuous online monitoring with industrial outputs and data connectivity, designed for long-term field service.

Where is a Methane(CH4) Analyzer used?

Problem: emissions risk and process inefficiency hide where methane goes unmeasured. Agitation: leaks, combustion imbalance, or biogas variability inflate costs and regulatory exposure. Solution: targeted CH₄ analytics align safety, compliance, and yield.

- Biogas/landfill & waste-to-energy: Optimize gas quality, track CH₄/CO₂ ratios, and document compliance. IR analyzers are a common choice for these streams.

- Oil & gas / city-gas leak detection: From fixed monitoring to vehicle-mounted laser methane systems for pipeline patrols, ESEGAS supports continuous and mobile CH₄ surveillance.

- Process gas & syngas: Multi-component IR-GAS-600 configurations measure CH₄ alongside CO/CO₂/O₂/H₂ for combustion tuning and safety interlocks.

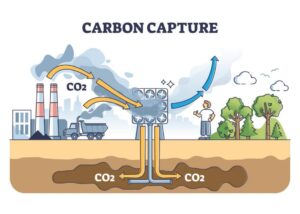

- GHG & environmental research: Methane is a potent GHG; analyzers provide the concentration data needed for inventories and mitigation strategies.

- Medical breath testing: Emerging applications pair CH₄ with H₂ analysis for GI diagnostics (e.g., SIBO/IBS workflows).

How do I select the right Methane(CH4) Analyzer for my conditions?

Problem: poor fit at specification time means higher OPEX later. Agitation: mis-matched range, sampling, or compensation drives drift and downtime. Solution: use a short, non-negotiable checklist.

- Range & resolution: Define normal and upset conditions; include safety margins.

- Sensing tech: IR/NDIR is the baseline; consider laser-based options for remote/leak tasks.

- Sampling & conditioning: Moisture/particulates? Specify filters, water traps, heated lines, or corrosion-resistant wetted parts.

- Cross-interference: Validate performance where other hydrocarbons or CO₂ are present.

- Compliance & area classification: If hazardous area, align with site codes and protection methods.

- Integration: Confirm 4–20 mA/Modbus/relays, alarm setpoints, and historian/SCADA hooks.

- Vendor platform: For multi-gas needs, leverage IR-GAS-600 family to consolidate instruments.

How do we turn Methane(CH4) Analyzer data into decisions?

Problem: raw ppm isn’t action. Agitation: without clean interfaces and alarm logic, data won’t prevent incidents. Solution: wire for decisions from day one.

- Controls: Map threshold alarms to interlocks (flares, shutoffs, ventilation).

- Analytics: Trend CH₄ with O₂/CO/CO₂ for combustion health and efficiency.

- Connectivity: Standard analog/digital outputs feed PLC/DCS and cloud historians for reporting and ESG workflows. (Industry practice.)

What about maintenance and calibration?

Problem: frequent manual calibration steals uptime. Agitation: wet, acidic, or dusty gases accelerate drift. Solution: align preventive maintenance with sampling quality.

- Intervals: Establish zero/span checks based on gas cleanliness and duty cycle; trace work may require tighter intervals.

- Sample conditioning: Drying/filtration reduces optical fouling and stabilizes baselines—especially in biogas and wastewater applications.

- Records: Log calibrations and alarms for audits and continuous improvement.

Conclusion

A methane analyzer translates invisible risk into actionable numbers. ESEGAS’s Methane(CH4) Analyzer—built on the IR-GAS-600 platform—pairs trace-level sensitivity with industrial integration, from biogas skids to pipeline patrols and research labs. If you’re scoping a project now, line up your range, sampling, and outputs, then request the detailed spec sheet or an application review from the ESEGAS team to right-size your build.