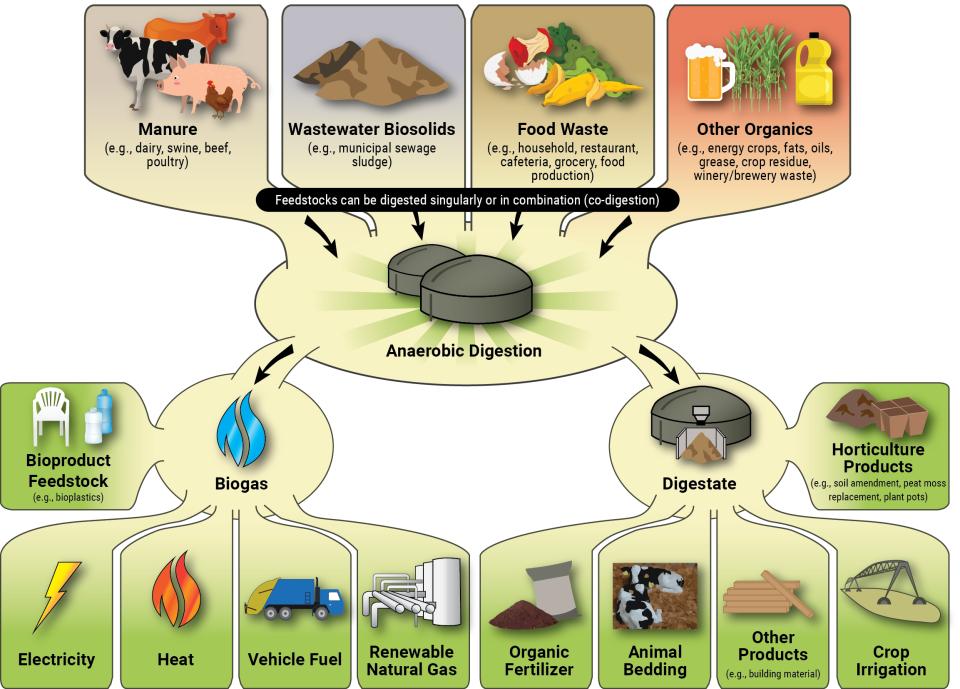

Anaerobic Digestion (AD) is a sophisticated biochemical process. It relies on a delicate balance of microbial consortia to break down organic matter. The resulting biogas is the immediate, real-time report card of this microbial ecosystem. Precise measurement is therefore non-negotiable.

The transition from a stable lab environment to a working AD plant presents immense analytical challenges. A portable biogas analyzer must meet stringent demands to ensure data trustworthiness. It must be rugged enough to withstand the corrosive atmosphere of a gas plant. It must be fast to enable rapid spot-checking across dozens of sample points. Furthermore, it must remain stable across wide temperature and humidity variations. If the analyzer drifts under field stress, its diagnostic value is zero. Operators rely on this instrument for measurement validation. They use it to check gas quality at the digester head, post-scrubbers, and near the flare. This demanding application requires analytical technology built specifically for the biogas industry.

How Does NDIR Technology in a Portable Biogas Analyzer Accurately Measure Bulk CH4 and CO2?

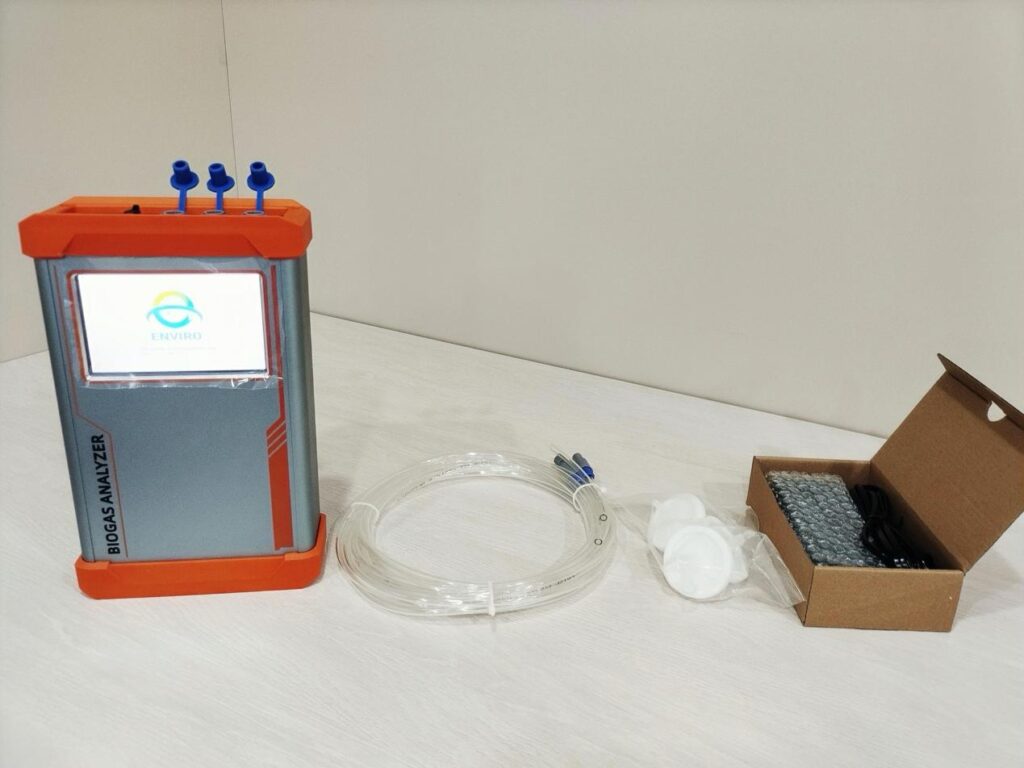

(ESEGAS’s portable biogas analyzer)

For analyzing the main components of biogas, we rely on Non-Dispersive Infrared (NDIR) technology. This method exploits a basic physical law. Gas molecules like CH4 and CO2 absorb infrared (IR) light at unique, specific wavelengths. The analyzer beams IR light through the gas sample. It then measures the remaining energy on the detector. The amount of light absorbed directly correlates to the gas concentration. This principle provides two critical advantages in biogas analysis. NDIR offers high selectivity. It is also inherently robust against chemical sensor poisoning. This makes NDIR ideal for measuring the high concentrations typical of biogas. These bulk measurements usually range from 45% to 65% Methane (CH4).

While powerful, NDIR sensors face a significant field challenge: cross-sensitivity. Specifically, water vapor interference is common in biogas, which is often saturated. Water molecules absorb infrared energy similarly to CH4. When water vapor is present, it causes falsely low CH4 readings. This compromises energy calculations and billing accuracy. Advanced portable biogas analyzers address this through sophisticated internal gas conditioning. The analyzer first pulls the sample through robust particulate filters. Crucially, it then employs efficient cooling systems or chemical dryers. These processes strip out excess moisture. This critical engineering step ensures that the final sensor measurement is pure and highly accurate. The data reflects true gas quality, not just humidity levels.

How Does the Portable Biogas Analyzer Manage Corrosive H2S and Dangerous O2 with Electrochemical Sensors?

While NDIR handles the bulk gases, we need a different technology for critical trace components. Electrochemical Sensors are the go-to solution for measuring Hydrogen Sulfide (H2S). The H2S gas diffuses through a membrane onto a sensing electrode within the cell. This diffusion triggers an electrochemical reaction. The resulting electrical current is precisely proportional to the H2S concentration. This technology is sensitive and fast. However, H2S poses specific challenges. At the digester source, concentrations can spike to over 4000 ppm. The sensor must handle this high range capacity. Furthermore, due to the nature of the chemical reaction, these sensors have a finite lifespan. They require periodic replacement, unlike NDIR sensors.

Electrochemical sensors are also vital for monitoring Oxygen (O2). Measuring O2 fulfills a crucial dual necessity. First, it addresses Safety. Any O2 ingress introduces the risk of explosion when mixed with CH4. Plant engineers must quickly confirm safe, low-oxygen levels. Second, O2 analysis is critical for Process Health. Oxygen is toxic to the methanogenic bacteria that produce biogas. Detecting its presence signals damaging air leaks in the collection system. The portable analyzer quickly identifies O2 intrusion points. This allows operators to isolate and repair the leak, protecting both the valuable microbial community and the plant infrastructure. The speed of the electrochemical sensor is a key advantage here.

How Does Portable Biogas Analysis Enable Predictive Maintenance and Process Control?

The true value of a portable biogas analyzer extends past simple gas readings. It becomes a diagnostic tool for the entire biochemical process. Consider the critical VFA Alkalinity ratio, the primary indicator of digester health. Traditional checks involve time-consuming lab wet chemistry. However, a rapid CO2 measurement from the portable unit provides the fastest on-site diagnosis. A sudden, sustained increase in CO2 concentration immediately alerts operators. This spike signals metabolic stress or Digester Sourness. The rapid warning allows immediate adjustment of the feeding rate. This intervention can prevent a total digester failure, which is extremely costly and time-consuming to recover from.

Portable analyzers transform network troubleshooting through the Grid Mapping Technique. Advanced units often include GPS capabilities. Engineers systematically measure gas composition across numerous points: every digester headspace, manifold valve, and pipe flange. The GPS tags each measurement. This creates a high-resolution, spatial map of the AD plant’s gas network. This map immediately highlights anomalies. It identifies specific zones with excessive H2S spikes. It pinpoints subtle O2 air ingress locations. This data is invaluable for optimizing operations. Operators use it to precisely focus pre-treatment efforts or place gas scrubbing media exactly where needed. This approach replaces guesswork with targeted, data-driven action.

Conclusion: From Measurement to Predictive Maintenance

We have detailed the advanced technical capabilities that define modern portable analysis. The synergistic combination of NDIR technology for high-accuracy bulk CH4 and CO2 measurement, along with highly sensitive Electrochemical Sensors for H2S and O2, creates a robust platform. An exemplary instrument, such as the ESEGAS handheld portable biogas analyzer IR-GAS-400H, embodies this fusion. It delivers laboratory-grade diagnostics directly into the hands of the plant engineer. This mobile diagnostic power ensures that every sample point—from the digester’s headspace to the gas flare—is quickly, accurately, and reliably analyzed, guaranteeing data integrity.

Ultimately, advanced portable analysis transforms process oversight. We move beyond simple passive monitoring. The actionable data generated by these analyzers empowers predictive maintenance. Engineers can anticipate H2S-related corrosion issues before engine damage occurs. They can diagnose Digester Sourness hours before totaling biological collapse. This proactive process control is the key to sustained profitability. By integrating this mobile, high-resolution analysis into daily routines, AD plants ensure continuous compliance, maximize energy output, and drastically reduce costly operational downtime. Investing in a professional-grade portable biogas analyzer is investing in the long-term health of your facility.

If you want to get a tailored solution, contact with ESEGAS team!

Frequently Asked Questions (FAQ) on Portable Biogas Analysis

Q1: What is the primary technology used by a portable biogas analyzer to measure Methane (CH4) and Carbon Dioxide (CO2)?

A: Portable biogas analyzers primarily use Non-Dispersive Infrared (NDIR) technology for bulk gas measurement (i.e., CH4 and CO2). This method is highly effective because these gases absorb specific IR light wavelengths. NDIR is preferred for these high concentrations (e.g., 45% to 65% CH4) due to its high selectivity and excellent long-term stability compared to chemical sensors.

Q2: Why must portable biogas analyzers use internal gas conditioning (like filters and coolers) before analyzing the biogas sample?

A: Biogas is often saturated with water vapor, which causes a phenomenon called cross-sensitivity in NDIR sensors. Water vapor absorbs IR light, leading to artificially low CH4 readings. Internal gas conditioning units (filters and coolers) efficiently remove particulates and excess moisture, ensuring the sensors measure only the gas components, thereby guaranteeing high data accuracy for energy calculation and compliance.

Q3: Which sensor technology is used to measure corrosive H2S (Hydrogen Sulfide) in portable units, and why is its measurement critical?

A: Electrochemical Sensors (ECD) are used for measuring trace corrosive gases like H2S. These sensors generate an electrical current proportional to the gas concentration, offering high sensitivity (down to ppm levels). H2S measurement is critical because it is a severe corrosive agent. Keeping it below warranty limits prevents catastrophic damage and costly downtime for CHP engines and RNG upgrading equipment.

Q4: How does a portable biogas analyzer help diagnose “Digester Sourness” using simple gas readings?

A: Portable CO2 measurement acts as the fastest indicator of Digester Sourness (acid/alkaline imbalance). A rapid, sustained increase in CO2 concentration signals that the methanogenic bacteria are under stress, often due to an overload of volatile fatty acids (VFA). This immediate on-site data allows operators to make feeding rate adjustments quickly, preventing a complete and costly digester crash.

Q5: What is “Grid Mapping,” and how does a portable biogas analyzer enable this technique?

A: Grid Mapping is an advanced methodology where the portable biogas analyzer, often equipped with GPS, is used to take rapid, precise gas composition readings at numerous points across the AD facility (e.g., every digester and manifold). This creates a high-resolution spatial map that precisely identifies problem zones, such as the highest H2S source or the exact point of O2 air ingress, allowing for targeted, efficient troubleshooting and pre-treatment optimization.