CO₂ Gas Analyzer in Breweries, Undetected CO₂ variations can ruin beer quality or put workers at risk—are breweries unknowingly gambling with gas levels?

A CO₂ gas analyzer is essential in breweries to ensure product consistency, safeguard workers, and comply with safety regulations. Precision instruments like those from ESEGAS help breweries monitor, control, and optimize CO₂ levels across all stages of production.

Even if you already track CO₂ levels, understanding how advanced analyzers like those from ESEGAS work—and why they’re brewery-specific—can unlock greater consistency and efficiency in your operations.

What Is a CO₂ Gas Analyzer, and How Does It Work?

Not all CO₂ analyzers are made equal—understanding their core technology is essential to choosing the right one for your brewery.

A CO₂ gas analyzer is a precision instrument used to detect and quantify the concentration of carbon dioxide in a given environment or process stream. In breweries, where CO₂ is both a product of fermentation and a safety hazard, these analyzers serve two critical purposes: quality control and worker protection.

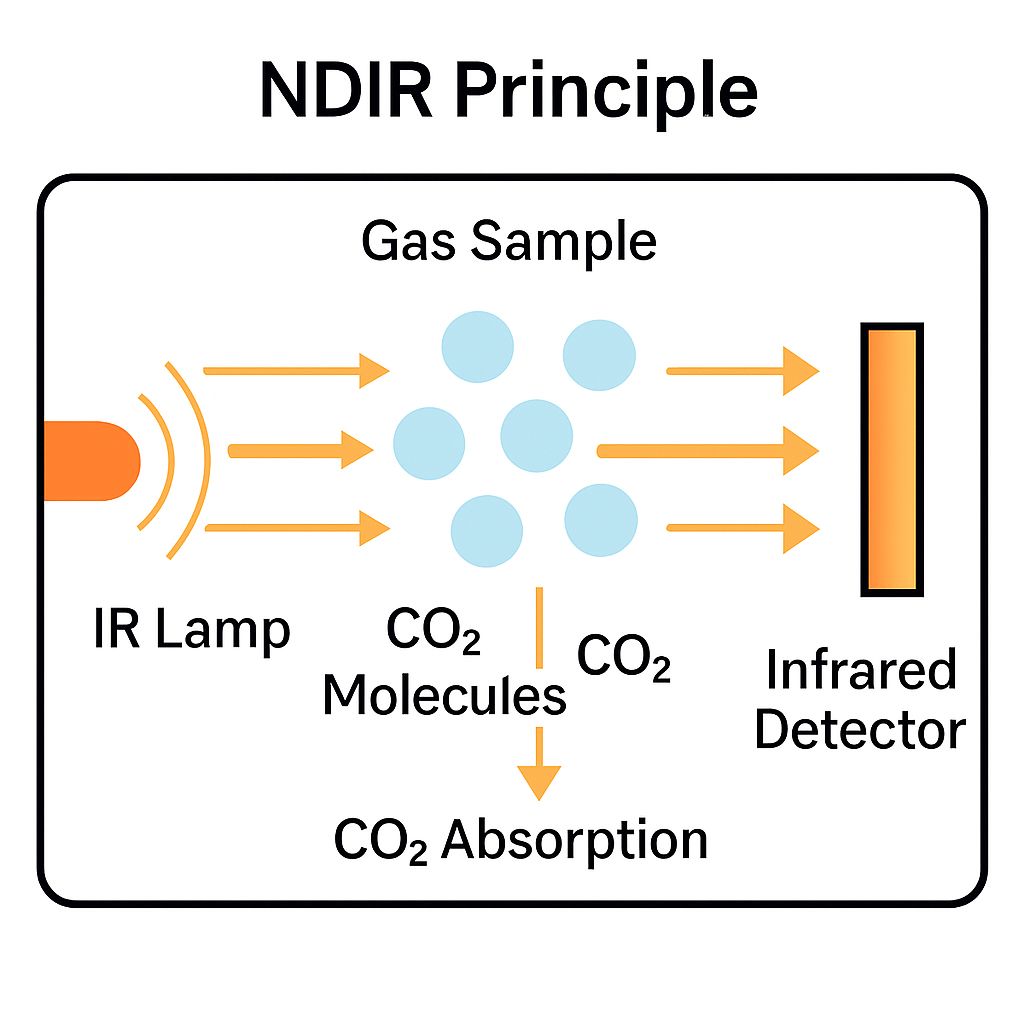

The most common and reliable type of CO₂ analyzer is based on Non-Dispersive Infrared (NDIR) technology. This method works by directing an infrared light beam through a gas sample. CO₂ molecules absorb specific wavelengths of infrared light. The analyzer measures how much light is absorbed and calculates the exact CO₂ concentration accordingly. This non-invasive method ensures continuous, accurate readings without altering the gas.

More advanced models, such as those developed by ESEGAS, offer enhanced features tailored to brewery operations. These include:

- Real-time digital outputs for automated control systems

- Temperature and pressure compensation for accurate readings under varying brewery conditions

- Self-diagnostics and long-term calibration stability

- Compact, stainless steel housings suitable for harsh or humid production areas

Some ESEGAS analyzers are also designed to be portable, enabling spot checks around fermentation tanks, bottling lines, and CO₂ recovery systems. Others are fixed-installation units integrated directly into fermentation or storage tanks for constant monitoring.

By using precise optical sensors and brewery-optimized firmware, ESEGAS CO₂ analyzers help maintain product consistency, prevent CO₂ buildup, and support seamless data logging for traceability.

Why Is CO₂ Gas Analyzer in Breweries Critical ?

Overlooked CO₂ levels can compromise both flavor and safety—precision is not a luxury, it’s a necessity.

In brewing, carbon dioxide is both a natural byproduct and a vital component of the final product. During fermentation, yeast converts sugars into alcohol and CO₂. This gas not only contributes to carbonation but also impacts pressure, taste, and shelf life. Without proper monitoring, CO₂ levels can fluctuate—leading to inconsistent beer, flat products, or over-carbonation.

But the risks go far beyond taste.

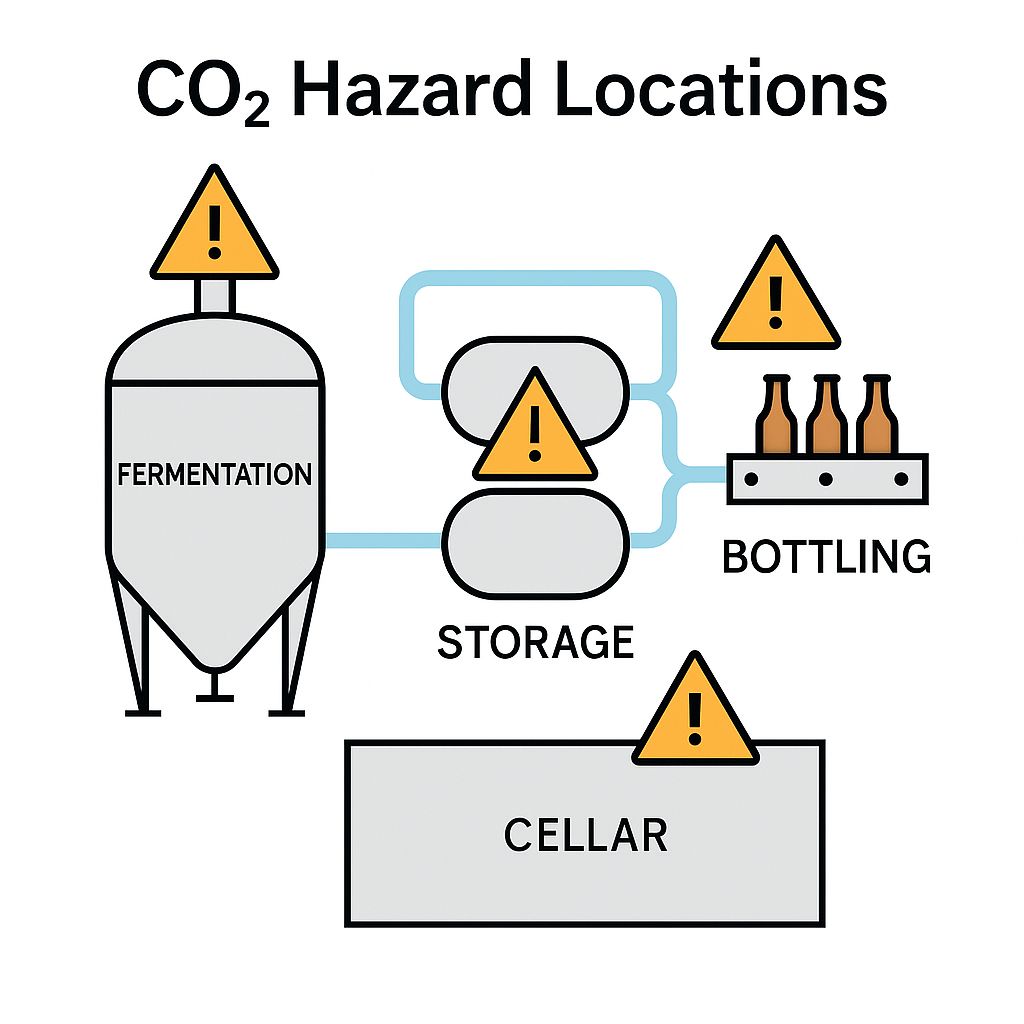

CO₂ is heavier than air, and in poorly ventilated spaces, it can displace oxygen. Exposure to high concentrations can cause dizziness, unconsciousness, or even suffocation—a danger especially present near fermentation vessels or in cellars. Many brewery accidents are linked to unmonitored CO₂ buildup. That’s why organizations like OSHA and local health authorities mandate strict CO₂ exposure limits.

CO₂ analyzers—especially those engineered by ESEGAS—provide continuous, real-time tracking of CO₂ levels, alerting staff before conditions become hazardous. These analyzers support both process control and environmental monitoring, ensuring the beer is brewed precisely, and the working environment remains safe.

In addition, consistent CO₂ management reduces waste, lowers the risk of packaging defects, and ensures regulatory compliance—all of which contribute directly to brand reputation and cost control. Simply put, with a trusted analyzer like one from ESEGAS, breweries can protect their beer, their people, and their bottom line.

At Which Stages Should Breweries Monitor CO₂?

CO₂ control isn’t just a one-time task—it’s a critical checkpoint throughout the entire brewing cycle.

Effective CO₂ monitoring must span every key stage of the brewing process, not just fermentation. Each phase presents unique risks and quality considerations, and overlooking any step can lead to off-spec products, safety violations, or equipment damage. Advanced systems like those from ESEGAS are designed to provide precise, continuous measurements across all these environments.

Here’s where breweries should focus CO₂ analysis:

- Fermentation: As yeast metabolizes sugars, CO₂ is rapidly produced. Monitoring here prevents over-pressurization and supports accurate modeling of yeast activity and batch timing.

- Maturation and Conditioning: CO₂ can accumulate in sealed tanks. Continuous measurement ensures carbonation stability and supports natural conditioning processes without pressure spikes.

- Storage and Transfer: CO₂ can leak or become trapped in pipeline dead zones. Real-time tracking ensures gas balance is maintained when beer is moved or stored.

- Bottling and Packaging: Accurate dosing is essential to achieve desired carbonation levels without over-fizzing or under-pressurization. ESEGAS analyzers integrate with filling lines to automate this process precisely.

- Cellars and Confined Spaces: Ambient CO₂ can rise undetected in underground or poorly ventilated areas. Wall-mounted or portable ESEGAS detectors can continuously safeguard staff from harmful exposure.

With multi-point CO₂ surveillance using instruments like ESEGAS analyzers, breweries ensure product consistency, equipment protection, and workplace safety, all while meeting modern regulatory expectations.

ESEGAS Carbon Dioxide (CO2) Gas Analyzer

ESE-IR-100 Carbon Dioxide (CO2) gas analyzer is a new type of infrared gas sensor independentlydeveloped by our company for environmental monitoring and industrial site emission gas analysis. High-precision, high-resolution probes and gas absorption cells with completely independent intellectual property rights are used. The sensor has the characteristics of high precision, good stability and fast response time.

- Measurement Principle: NoDispersed infrared(NDIR)

- Measuring Range:CO2(0~200/500/10000)μmol/mol;(Two-component analyzer:Other ranges or gas components can be customized)

- Sample Gas Flow:(0.8~1.5)L/min;

- Response Time≤60Second

- Measurement Error:±2.0%FS

- Drift:±2.0%FS

- Repeatability:2.0%

- Preheat Time≤60min

- Input/Output Signals:Analog quantity/(4~20)mA and switching quantity; reserved expansion interface

- Digital InterfaceRS232/RS485

How Can CO₂ Analyzers Improve Efficiency and Regulatory Compliance?

You’re not just measuring gas—you’re optimizing operations and staying legally protected.

In today’s brewery environment, balancing efficiency with regulatory compliance is no longer optional—it’s essential. CO₂ analyzers play a crucial role in helping breweries achieve both by monitoring performance, reducing waste, and ensuring workplace safety in accordance with national and international standards.

From an efficiency standpoint, CO₂ analyzers enable real-time leak detection, which minimizes gas loss during fermentation, transfer, and bottling. By identifying CO₂ irregularities early, breweries can correct process imbalances, maintain ideal carbonation, and reduce product rejection due to quality fluctuations. Instruments from ESEGASoften feature automated alarm systems and data logging, allowing breweries to adjust settings proactively based on trends rather than reacting to faults after the fact.

In terms of compliance, occupational safety standards such as those from OSHA, EH&S, and local workplace hazard regulations require facilities to maintain safe ambient CO₂ levels. Prolonged exposure to concentrations above 5,000 ppm can be dangerous for staff, especially in confined spaces. ESEGAS analyzers support these compliance goals by offering ambient CO₂ monitoring systems with highly sensitive sensors and built-in alerts to prevent violations and potential liability.

Moreover, many breweries use CO₂ recovery systems. Without accurate monitoring, excess pressure or impurity buildup can damage equipment or violate environmental discharge limits. ESEGAS analyzers help ensure these recovery systems operate within design parameters, promoting sustainability without sacrificing safety or compliance.

In summary, ESEGAS CO₂ analyzers are not just tools—they are strategic assets that help breweries optimize every liter of beer while protecting their workforce and reputation.

Conclusion

CO₂ control is not optional in brewing—it’s foundational. With precision instruments from ESEGAS, breweries can ensure safety, flavor, and efficiency from fermentation to final packaging. if you have any questions, please contact us!