Cement is an indispensable material in the construction industry, and the gases emitted during cement production pose a potential threat to the environment and human health. To achieve sustainable development of the production process, cement plants need to employ advanced technology to monitor, control, and optimize gas emissions. In this context, gas analyzers have become one of the indispensable tools in cement production. In this blog, the application of gas analyzers in cement plants will be discussed in depth, including their basic principles and types, application scenarios, technical details, and optimization, as well as challenges and future perspectives. By analyzing these contents in detail, we can better understand the importance of gas analyzers in cement production and the key role they play in promoting the cement industry towards environmental protection, high efficiency, and safety.

Gases that May Be Generated During Cement Production

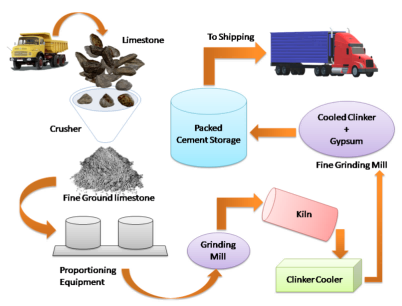

Cement production is a complex and energy-intensive industrial process involving multiple steps from raw material extraction to final product packaging. Understanding this process is critical to understanding the use of gas analyzers in cement plants, as they play a key role in ensuring production efficiency, product quality, and environmental protection.

- Raw material preparation

The main raw materials for cement include limestone, clay, iron ore, and sand. These materials are first extracted in a mine, passed through a crusher that breaks the large stones into smaller particles, and then sent via a conveyor belt to the raw material storage area. From there, the raw materials are further processed, often including blending and grinding, to ensure the quality and consistency of the finished cement. The key to this stage is to maintain a balanced chemical composition of the raw materials, which directly affects the efficiency of the firing process and the performance of the final product.

- firing process

The well-mixed raw materials are then fed into a kiln where they are fired at high temperatures. This process is the most critical step in cement production. In the rotary kiln, which is several hundred meters long, the raw materials are fired at a temperature of about 1450°C to produce a mature product. This high-temperature process involves not only physical melting but also a series of complex chemical reactions, such as the decomposition of calcium carbonate into calcium oxide and carbon dioxide. The gases produced by these reactions are the main target of gas analyzers, as they are essential for adjusting production parameters, optimizing energy use and reducing emissions.

- Finished Product Preparation

Once the clinker has been discharged from the kiln and cooled, it is sent to the mill for further grinding, usually with a small amount of gypsum added to regulate the setting time of the cement. The end product at this stage is a fine powdered cement, which is then packaged and transported to various construction sites. At the finished product stage, gas analyzers are less commonly used directly, but gas monitoring data throughout the production process can be used to retrace and optimize operational efficiency and environmental performance at each step.

As we have seen from the detailed descriptions above, gas analyzers play a vital role at every stage of production, not only ensuring that the process is efficient and safe but also helping companies to meet increasingly stringent environmental requirements. In the next sections, we will look more closely at the technical details and advantages of these devices in specific applications.

Basic Principles and Types of Gas Analyzers for Cement Plants

In cement production, gas analyzers are an important tool for monitoring and controlling key environmental and process parameters. Based on different detection technologies, these devices provide real-time data on the composition of the gases in the kiln, which is essential for optimizing the production process and reducing environmental impact.

- rationale

Gas analyzers work based on physical and chemical sensing techniques to determine the concentration of specific gas molecules by detecting and analyzing their optical or electrochemical properties. Commonly used techniques include infrared (IR) spectroscopy, ultraviolet (UV) spectroscopy, Laser Absorption Spectroscopy (TDLAS), etc. Each of these techniques has its own unique characteristics. Each technique has its own unique advantages and application scenarios. Selecting the appropriate gas analysis technique is critical to ensure data accuracy and long-term stable instrument operation.

- Infrared gas analyzer

An infrared gas analyzer detects and quantifies gas composition by measuring the ability of gas molecules to absorb specific infrared wavelengths. It is particularly suitable for detecting molecules such as carbon dioxide and carbon monoxide, as these gases have distinct absorption peaks in the infrared spectrum. Infrared analyzers are suitable for environmental monitoring and process control because they provide fast, non-invasive measurements.

- UV Gas Analyzer

UV gas analyzers utilize the absorption properties of gas molecules in the ultraviolet region for detection. This type of analyzer is well suited to detect gases such as sulfides and chlorides, which have strong absorption lines in the UV spectrum. UV technology is particularly effective in detecting low concentrations of pollutants, which is important to ensure that kiln emissions meet environmental standards.

- Laser Gas Analyzer

The Laser Gas Analyzer (TDLAS) is a technology that uses a tunable laser to quantitatively analyze gas components. Highly accurate and selective gas detection is achieved by precisely adjusting the laser wavelength to match the absorption lines of specific gas molecules. This type of analyzer is particularly effective when small molecule gases such as ammonia or methane need to be measured with high precision.

- Parametric Gas Analyzer Selection Basis

There are several key factors to consider when selecting a gas analyzer:

Accuracy: Analyzers need to be able to provide accurate measurements to ensure process optimization and environmental compliance.

Response Time: A fast response time is critical to capture rapidly changing gas concentrations in the process.

Maintenance requirements: The ease and cost of maintaining the equipment is also an important consideration, especially in cement plants that work in dusty, hot, and corrosive environments.

By choosing the right gas analysis technology for specific application needs, cement plants can effectively monitor and control production processes, optimize operational efficiency, and reduce energy consumption, while ensuring compliance with regulatory requirements for environmental protection. In the next section, we look at how these analyzers are specifically used in cement plants and how they can help to improve production efficiency and environmental performance.

The Gas Analyzer Application in Cement Plants

Gas analyzers play a key role in the cement manufacturing process and their applications cover a wide range of areas, including kiln emissions monitoring, process control, and equipment safety. We explore these application scenarios in more detail below:

1. Monitoring of kiln emissions:

Gas emissions from kilns are a significant environmental issue during cement production. The main application of gas analyzers in this segment is to monitor the composition of the gases emitted from the kiln to ensure that they are within acceptable limits to comply with environmental regulations and standards. The main gases monitored include:

- Carbon Monoxide (CO): Carbon monoxide is a toxic gas produced by incomplete combustion, and its excessive emissions can be harmful to the environment and human health.

- Sulfur Dioxide (SO2): Sulfur dioxide is an oxide of sulfur in fuels, and excessive emissions can lead to acid rain and air pollution.

- Nitrogen oxides (NOx): Produced by the reaction of nitrogen and oxygen during high-temperature combustion, nitrogen oxides are harmful to the atmosphere and are one of the main causes of acid rain.

Through real-time monitoring and analysis of these gases, cement plants can take timely measures, such as adjusting fuel ratios and optimizing combustion parameters, to reduce emission concentrations and protect the air quality of the surrounding environment and communities.

2. Process control:

Gas analyzers play an important role in all stages of cement production, especially during kiln firing. By monitoring the gas composition in the kiln in real-time, such as oxygen concentration, combustion products, etc., precise process control can be realized, thus achieving several objectives:

- Optimizing combustion efficiency: Oxygen concentration is one of the most important parameters affecting combustion efficiency. By monitoring the oxygen concentration in the kiln, the cement plant can adjust the ventilation system, fuel supply, and other parameters to achieve optimal combustion efficiency, reduce energy consumption, and improve productivity.

- Control of clinker quality: The gas components produced during the combustion process have a direct impact on the quality of clinker. By monitoring and controlling the gas composition, the cement plant can adjust the combustion parameters to control the composition and quality of the clinker and ensure the quality and stability of the final product.

- Reduced environmental impact: Optimizing the combustion process not only reduces energy consumption but also reduces the emission of harmful gases, thus reducing the negative impact on the environment and protecting the safety and stability of the surrounding ecosystem.

Through these precise process controls, cement plants can increase productivity and reduce production costs, while minimizing pollution and damage to the environment and achieving sustainable development.

3. Equipment safety:

In a high-temperature and high-pressure cement production environment, equipment safety is an important consideration. The application of gas analyzers in this aspect is mainly to monitor the possible dangerous gases in the kiln, such as carbon monoxide, ammonia, etc., to ensure the safety of production equipment and workers. Through real-time monitoring and alarm systems, potential safety hazards can be detected and dealt with promptly to ensure the safe and stable operation of the production process.

In summary, the applications of gas analyzers in cement plants cover a wide range of aspects such as kiln emission monitoring, process control, and equipment safety. Through these applications, cement plants can achieve precise monitoring and control of the production process, thereby increasing productivity and reducing costs, while protecting the environment and maintaining worker safety. In the next section, we look at further applications of gas analyzers for technical detail and optimization.

Technical Details and Optimization

The application of gas analyzers in cement plants requires consideration of a wide range of technical details and optimization aspects, including trends in gas analysis technology, installation and maintenance points, as well as data integration and intelligent applications.

1. Trends in gas analysis technology:

As technology continues to advance, gas analysis techniques are also evolving, tending toward higher accuracy, faster response times, and a wider range of applications. Future trends include:

- Miniaturization and Portability: With the advancement of sensor technology, gas analyzer equipment is moving towards more miniaturization and portability to meet the needs of different work scenarios, such as on-site monitoring and mobile monitoring.

- Multi-Parameter Integration: Future gas analyzers may be able to achieve multi-parameter integration, i.e., monitoring multiple gas components simultaneously on the same device to improve detection efficiency and accuracy.

- Intelligence and automation: Gas analyzers may integrate intelligence and automation features to automatically adjust and optimize production parameters through data analysis and learning algorithms to improve production efficiency and environmental protection.

2. Installation and maintenance points:

In a cement plant, the installation and maintenance of gas analyzers are crucial and directly affect the stability of the equipment and the accuracy of the data. Generally speaking, the following points need to be considered when installing and maintaining:

- Location: The location of the gas analyzer needs to be chosen for representativeness and convenience of gas sampling, usually at the kiln outlet, chimney, etc.

- Environmental adaptation: Gas analyzers need to be able to cope with the high temperatures, dust, and corrosiveness of the cement production environment, so the materials and sealing of the equipment need to comply with the appropriate standards.

- Regular Maintenance: Gas analyzers require regular maintenance and calibration, including cleaning the optical path, replacing sensors, and calibrating the instrument to ensure data accuracy and stability.

3. Data integration and intelligent applications:

With the development of IoT technology, gas analyzers can integrate data with other production equipment and systems to achieve intelligent applications such as:

- Data monitoring and analysis: Integrate the gas analyzer data with other production data, realize real-time monitoring and early warning through the data monitoring and analysis system, discover production abnormalities, and take measures in time.

- Remote control and regulation: Based on the Internet of Things (IoT) technology to realize remote monitoring and remote regulation, the cement plant can realize intelligent production management and improve production efficiency and quality.

In summary, the application of gas analyzers in cement plants needs to take into account a variety of technical details and optimization aspects, including the development trend of gas analysis technology, installation and maintenance points, as well as data integration and intelligent applications. Through reasonable technology selection and optimized management, cement plants can give full play to the role of gas analyzers to improve production efficiency and reduce costs, while protecting the environment and maintaining worker safety.

The Practical Cases of Gas Analyzers Used in the Cement Industry

Globally, many cement plants have begun to use gas analyzers to monitor and control gas emissions during the production process, optimize combustion efficiency, and improve production safety. Below are some specific case studies demonstrating the successful use of gas analyzers in cement plants:

- Case 1: Emission monitoring and control at a cement plant in the United States of America

The cement plant is located in the United States. In order to meet the strict environmental regulations and reduce the impact on the environment, the plant introduced an advanced gas analyzer system for monitoring and controlling the composition of the emitted gases. Through real-time monitoring and analysis of sulfur dioxide, nitrogen oxides and other harmful gases emitted from the chimney, the plant was able to adjust the combustion parameters in a timely manner and control the concentration of gas emissions within a reasonable range, which effectively reduced the pollution to the surrounding environment and gained the recognition of the governmental regulatory authorities.

- Case 2: Energy optimization and production control in a European cement plant

This cement plant in Europe uses an advanced gas analyzer system for real-time monitoring of gas composition and combustion efficiency in the kiln. By accurately controlling parameters such as oxygen concentration and fuel supply, the plant has successfully optimized the combustion process, reduced energy consumption and increased production efficiency. In addition, the gas analyzer is able to detect possible dangerous gases, such as carbon monoxide, in the furnace in real time, ensuring the safety of production equipment and workers.

- Case 3: Intelligent production management at a cement plant in Asia

At a cement plant in Asia, an intelligent gas analyzer system was introduced to achieve intelligent management of the production process. Through data integration with other production equipment and systems, the plant is able to realize remote monitoring and control, detect production anomalies and take measures in time. At the same time, the gas analyzer system can also automatically adjust the production parameters to achieve the goal of optimizing the production process, improving production efficiency and product quality.

The Challenges and Future Prospects

Although the use of gas analyzers in cement plants has been a remarkable success, there are still some challenges to be faced, as well as an exciting outlook for the future.

1. Technical challenges:

Accuracy in High Temperature and Dusty Environments: Cement production processes, with internal kiln temperatures up to thousands of degrees Celsius, accompanied by large amounts of dust generation, pose a challenge to the performance of gas analyzers. How to maintain measurement accuracy and stability in such extreme environments is a technical challenge that needs to be solved.

Detection of low-concentration gases: Some important gas components, such as nitrogen oxides and sulfur dioxide, tend to have low concentrations in the cement production process and therefore require higher sensitivity and more accurate detection techniques.

2. Environmental challenges:

- Stricter Emission Standards: As environmental awareness increases and government requirements for environmental protection become stricter, cement plants need to continually reduce their emission standards to minimize pollution and impact on the environment. This places higher demands on the performance and data accuracy of gas analyzers.

- Carbon Neutral and Sustainable: As the concepts of carbon neutrality and sustainability become more prevalent, cement plants need to further reduce their carbon emissions and explore greener, more sustainable production methods. Gas analyzers will play a vital role in this process, providing key data to support cement plants in achieving low-carbon production.

3. The prospects:

- Integration of the Internet of Things and Big Data Technology: With the continuous development and popularization of the Internet of Things and Big Data technology, gas analyzers will be used with other production equipment and systems for deeper data integration and intelligent applications to achieve comprehensive monitoring and management of the production process.

- Intelligent and Adaptive Control: Future gas analyzers will have stronger intelligent and adaptive control capabilities, and will be able to automatically adjust production parameters based on real-time data analysis to achieve intelligent optimization of the production process.

- The application of new sensing technology: new sensing technology continues to emerge, such as MEMS technology, fiber optic sensing technology, etc., which will provide breakthroughs for the development of gas analyzers, so that it has higher stability and reliability in high temperature and dust environments.

In summary, although the application of gas analyzers in cement plants faces some challenges, with the continuous progress and innovation of technology, as well as the continuous pursuit of environmental protection, its future development prospects are still very broad. Through continuous technological innovation and application promotion, the gas analyzer will provide strong support for cement plants to achieve more efficient, more environmentally friendly, and safer production, and help the cement industry move towards a sustainable future.

Conclusion

The application of gas analyzers in cement plants has made remarkable achievements, providing important technical support for the monitoring, control, and optimization of the cement production process. By monitoring and analyzing the composition of emitted gases in real time, cement plants can effectively reduce environmental pollution and improve production efficiency and quality. However, challenges include technical difficulties, environmental pressures, and the need for carbon neutrality. In the future, with the development of IoT and big data technology, gas analyzers will become more intelligent and adaptive, providing stronger support for cement plants to achieve more efficient, environmentally friendly, and safer production. Through continuous technological innovation and application promotion, the gas analyzer will inject new vitality into the cement industry as it moves towards a sustainable future. If you have any questions, please get in touch with us.