As the world pushes for an increased focus on clean energy and sourcing, power plants need to consider every aspect of their operation that impacts emissions.

Gas analyzers are a great way to monitor and adjust operations accordingly to ensure regulatory compliance when it comes to managing fuel sources like natural gas.

Fuel cells also require continuous monitoring with a reliable gas analyzer to effectively optimize their processes, ensuring maximum efficiency and performance in all applications.

What Is A Gas Analyzer?

A gas analyzer is an instrument used to measure the amount and type of gases present in a particular mixture. It is used in the power plant industry to measure the composition of raw materials used in the plant and the output of the process.

The Importance Of Using A Gas Analyzer In The Power Plant Industry!

Gas analyzers are an essential tool in the power plant industry as they help to reduce operational costs, optimize energy production, detect plant malfunctions, comply with environmental regulations, and maximize energy production. Let’s take a deeper look into these benefits.

1. Accurate Measurement Of Emissions:

Gas analyzers accurately measure the different types of emissions coming from combustion processes, allowing operators to take corrective action quickly if necessary and ensuring that they can better comply with environmental laws and regulations in place.

This makes sure pollutant levels stay within acceptable limits as mandated by law while also maintaining high-efficiency standards for power plants.

2. Real-Time Monitoring:

By enabling real-time emission measurements, gas analyzers allow operators to supervise their processes more effectively and detect any process-related errors or malfunctions before they become costly issues.

3. Reducing Operational Costs:

By monitoring combustion processes in real-time, gas analyzers help power plants reduce energy consumption while maintaining efficiency levels – leading to great economic cost reductions over the long run.

This is especially important for large-scale operations where opting for greater environmental sustainability entails considerable efforts from all departments within an organization.

4. Optimizing Energy Production:

Gas analysis enables plant engineers to calibrate turbines’ performance accurately during start-up phases as well as provide precise insight into burners’ fuel/air mixtures once operations are on board – thus enabling them to improve overall system throughput and optimize energy production. As a result, power plants can reduce emissions while ensuring maximum efficiency and productivity.

5. Preventing Unexpected Maintenance:

Power plants can better anticipate what kind of maintenance operations are necessary and when, since gas analyzers provide the data required to predict any potential failure points in advance – significantly reducing costs associated with unplanned or urgent repair works.

6. Detecting Plant Malfunctions:

Gas Analyzers identify irregularities during combustion processes before they become major issues – allowing plant operators to intervene quickly thus preventing more costly consequences later on (e.g. reduced energy production or environmental liabilities).

7. Ensuring Process Safety:

Gas analyzers help to ensure that equipment operating in power plant facilities will be running safely and optimize combustion processes – drastically reducing the risk of explosions, fire accidents, or health hazards due to sulfur dioxide (SO2), carbon monoxide (CO), and other pollutants emitted by coal-fired plants into their surrounding environment.

8. Complying With Environmental Regulations:

By accurately measuring emissions, gas analyzers allow plant operators to remain compliant with existing environmental laws and regulations stipulated by local authorities – averting expensive fines or worse.

9. Improving Efficiency:

Gas analyzers provide the data needed for engineers to optimize processes such as turbine regulating, fuel composition, or air-fuel mixture in combustion systems– all of which lead to improved energy production efficiencies over time and reduce operating costs.

10. Maximizing Energy Production:

Gas analyzers allow plant operators to better control how much fuel is used during combustion processes and can help identify which types of fuels are the most efficient.

As a result, this helps maximize the amount of energy produced while ensuring emissions levels remain safe for both workers in power plants as well their surrounding environments.

Gas analyzers work by measuring the amount and type of gases present in a particular mixture. They are used to detect the presence of harmful gases such as carbon monoxide, sulfur dioxide, nitrogen oxides, and hydrocarbons. The steps below will answer to how gas analyzer work:

Step 1: Gas Enters The Analyzer And Is Heated To A Specific Temperature.

The gas passes through an inlet tube and then into a chamber, where it is heated by infrared radiators or resistive heating elements up to its required operating temperature before being sent for analysis.

Step 2: Gas Is Measured Using A Sensor.

Gas is measured using sensors such as thermocouples and electrochemical cells which detect different gases depending on the type of sensor used.

Measurements are taken every few seconds and stored for further analysis. On-board software then processes the data and displays the results on an LCD screen.

Step 3: The Data Is Processed And Analyzed.

After the measurements are taken, a computer program processes all of the gathered information to determine what types of gases were present in the sample.

This can involve complex calculations depending on how accurate or specific results need to be obtained from this type of device.

Step 4: The Results Are Displayed.

Once all analyses have been completed by the gas analyzer, they will be presented in a numerical or graphical format on the device’s display.

It will also provide information such as temperature and pressure readings, which can be used to further analyze different variables related to specific types of gases present.

Several types of gas analyzers are available on the market. These include electrochemical, infrared, and mass spectrometers. Each type of gas analyzer has its advantages and disadvantages. Let’s take a look at each type in more detail.

■ Electrochemical Gas Analyzer :

This type of gas analyzer uses electrodes to measure the concentrations of gases such as oxygen, carbon dioxide, and hydrogen sulfide.

The advantage is that the measurement can be very accurate; however, they tend to have slow response times which makes them better suited for applications that require long-term measurements rather than short-term ones.

■ Infrared or TDL Gas Aanalyzer :

Infrared spectroscopy works by analyzing the light that has been bounced off a sample and then assessing the frequency of wavelengths.

This type of gas analyzer is used when it’s important to detect very small concentrations or trace amounts in gases as well as for monitoring changes over time.

The disadvantage of infrared spectroscopy is that its sensitivity can be hindered by environmental conditions such as humidity levels, making accuracy difficult at times

■ Mass Spectrometer :

Mass spectrometers work by breaking molecules down into fragments which are measured based on their mass-to-charge ratio (m/z). These devices provide high-resolution measurements from complex samples quickly; however, they tend to have higher costs associated with them and require more sophisticated instrumentation due to their complexity.

With proper calibration, mass spectrometers can be used for a wide variety of applications.

How to choose a gas analyzer that is right for you sometimes becomes a tricky question. When selecting a gas analyzer for power plant applications, it is important to consider several factors. Below are some of the key points to keep in mind:

1. Gas Detection Range:

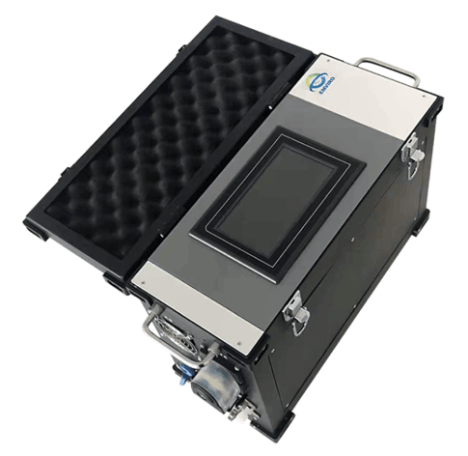

What range of gases will you be monitoring? Different gas analyzers have different detection capabilities. EseGas has a wide range of reliable and accurate advanced infrared (IR) absorption spectroscopy-based technologies optimized for power plant applications, including products such as Laser Point Detectors/Multiplexers/Portable TDL Laser Gas Analyzer that measure multiple components simultaneously in the ultra-short concentration ranges from parts per billion to percent levels with excellent accuracy & fast response times

2. Accuracy Requirements:

When selecting an appropriate measurement technology it’s critical to consider what level of accuracy is required. As most combustible fuels contain various compound constituents the chosen analyzer must offer outstanding resolution between individual compounds when measuring their concentrations at either trace or percentage levels.

EseGas uses proprietary software algorithms offering fast averaging speed which prevents sample rate bottlenecks while maintaining high precision data readings over time extending calibration cycles and reducing costs significantly compared to other vendors’ solutions available on market today.

3. Temperature & Humidity:

The type of analyzer to use in any given application should also be based on environmental conditions (such as temperature and humidity). EseGas’s NDIR Gas Analyzer and Emission Gas Analyzer are designed for power plant applications operating within extreme temperatures from -100C up to +200 °C, its inherent ruggedness offers reliable operation even when exposed to potentially corrosive media or wet atmospheres.

4. Installation Requirements:

Ease of installation together with calibration simplicity are key factors that need special consideration when selecting a gas monitoring system.

Moreover, most modern models offer flexible access management allowing both local and remote control capabilities via web browser like those offered by our cloud solution GAARD®AirGateway through an intuitive graphical user interface making it easier than ever before! All these features make it simpler and more cost-efficient while still maintaining high-precision real-time measurements throughout the entire operational lifetime in even the harshest environmental conditions.

These are some of the important considerations when selecting a gas analyzer for your power plant needs and many others too, such as cost efficiency and data analysis capabilities, software compatibility with existing or required third-party systems, etc.

EseGas provides reliable advanced infrared (IR) absorption spectroscopy-based technologies optimized for power plant applications to meet all these requirements while maintaining high levels of accuracy & fast response times!