Unleash the power of Syngas Analysis in Biomass Gasification Applications. The aim of this blog is to decode this subject. Delve deep into the process, its impact, and its benefits. An enlightening journey awaits.

Detailed Understanding of Biomass Gasification!

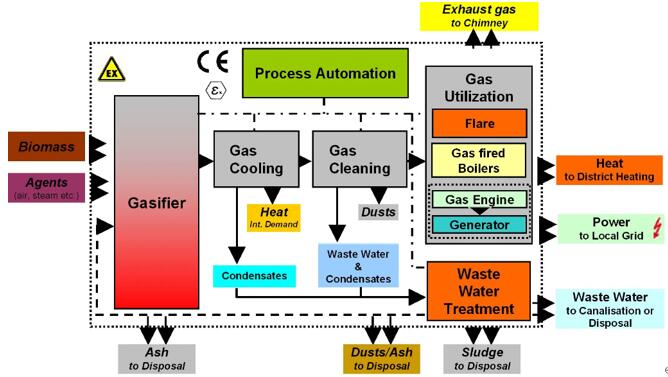

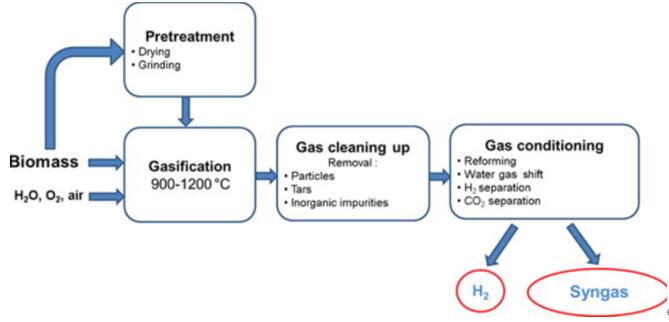

Process of Biomass Gasification

- Feedstock Preparation

Biomass feedstock starts as plant matter. It’s chopped, ground, and sorted. The aim is to make the feedstock uniform.

- Drying Stage

Feedstock undergoes drying. Under 105-110 degrees Celsius, moisture evaporates. Optimum moisture content is below 20%.

- Pyrolysis Phase

At 200-300 degrees Celsius, biomass starts decomposing. Volatile substances get released. What remains is char, a form of carbon.

- Combustion Stage

Char and volatile substances do burn in controlled oxygen. The result is heat, along with carbon dioxide and water vapor.

- Reduction Phase

With limited oxygen, carbon dioxide and water vapor turn into carbon monoxide and hydrogen. These are part of the final product, syngas.

- Gas Cleanup

Impurities like tar and ash particles get removed from syngas. Purification ensures the gas is suitable for energy conversion.

- Cooling Process

Hot syngas undergoes cooling. Drop in temperature condenses the water vapor, which gets separated from the gas.

- Gas Conditioning

Conditioning entails altering the syngas composition. Adjustments ensure the gas meets required specifications for further applications.

- Syngas Production

Carbon monoxide and hydrogen form the bulk of syngas. Other constituents include methane, nitrogen, and trace amounts of impurities.

- Energy Recovery

Syngas carries high energy content. It’s converted into electricity or biofuel in power generation units.

- Ash Disposal

The ash byproduct from gasification gets managed. It can be used in construction materials or safely landfilled.

Different Types of Biomass Used

- Sawdust

Leftovers from timber mills make excellent biomass. Sawdust gasification creates clean, energy-rich syngas.

- Agricultural Residues

Straw, husks, and stalks from farming get used. The residues, otherwise waste, contribute to renewable energy.

- Food Waste

Post-consumer food waste also gets gasified. Rotting fruits and vegetables transform into valuable syngas.

- Animal Manure

Livestock waste is another valuable biomass source. It produces biogas rich in methane.

- Grasses

Grass species such as switchgrass serve as efficient biomass feedstock. They’re converted into syngas in gasifiers.

- Nut Shells

Hard shells of nuts like almonds and coconuts can be gasified. The dense shells generate high-quality syngas.

- Bark

Bark from forestry activities makes a great biomass source. Gasification of bark produces energy-rich syngas.

- Paper Waste

Used paper products also serve as biomass. Recycling them into syngas reduces landfill waste.

- Municipal Solid Waste

Household garbage contains valuable biomass. Gasification converts the waste into clean, renewable energy.

Deep Dive into Syngas!

Definition and Composition of Syngas

Syngas is a blend of hydrogen (H2), carbon monoxide (CO), and minor amounts of carbon dioxide (CO2), gains use in biomass gasification applications.

Analysts identify these elements through Syngas Analysis. Syngas’s composition, vital in the energy sector, varies based on the gasification process.

Process of Syngas Production

– Gasification

Start the syngas production process with gasification. Gasification turns organic or fossil-based carbonaceous materials into carbon monoxide, hydrogen, and carbon dioxide.

– Steam Reforming

Next comes steam reforming. In this process, steam interacts with a hydrocarbon-based fuel to produce syngas. The high heat and pressure condition is crucial in steam reforming.

– Partial Oxidation

Partial oxidation follows steam reforming. A hydrocarbon fuel undergoes oxidation under high temperatures, producing a significant amount of syngas.

– CO2 Reforming

CO2 reforming involves reacting methane with carbon dioxide. You can count on this process to yield more syngas.

– Autothermal Reforming

Autothermal reforming is a combination of partial oxidation and steam reforming. Here, heat from partial oxidation supports steam reforming, resulting in syngas.

– Water-Gas Shift

The water-gas shift reaction comes next. The gas mixture undergoes further reaction with steam under a catalyst to produce more hydrogen and CO2.

– Methanation

Methanation involves the reaction of carbon monoxide and hydrogen to produce methane and water. The result is an increase in the syngas yield.

– Gas Cleaning

Gas cleaning is vital to remove impurities. The clean syngas gets ready for downstream applications.

– Hydrogen Separation

Hydrogen separation extracts hydrogen from the syngas. This separated hydrogen finds use in various applications.

– Gas Cooling

Finally, gas cooling cools the syngas for safe storage and transport.

| Process Name | Reaction Type | Feedstock | Product Gas | Main Equipment | Byproducts |

| Gasification | Heat + limited Oxygen | Coal, Biomass | Syngas | Gasifier | Ash, Tar |

| Steam Reforming | Heat + Steam | Natural Gas | Syngas | Reformer | Water, CO2 |

| Partial Oxidation | Heat + limited Air/Oxygen | Heavy Oil, Coal | Syngas | Reactor | CO2, Water |

| CO2 Reforming | CO2 + Heat | Methane | Syngas | Reactor | Water |

| Autothermal Reforming | Heat + Steam + Air/Oxygen | Natural Gas | Syngas | Reformer | Water, CO2 |

| Water-Gas Shift | Heat + Water Vapor | CO-rich Syngas | H2-rich Syngas | Reactor | CO2 |

| Methanation | Heat + H2 | CO, CO2 | Methane | Reactor | Water |

| Gas Cleaning | Chemical/Physical Process | Syngas | Cleaned Syngas | Scrubber | Sulfur, CO2 |

| Hydrogen Separation | Pressure swing | Syngas | Hydrogen | Membrane | CO2, CO |

| Gas Cooling | Heat Transfer | Hot Syngas | Cooled Syngas | Heat Exchanger |

Heat Energy |

Role of Syngas in Various Industries

- Chemical Manufacturing

In chemical manufacturing, syngas serves as a primary ingredient. Chemical engineers utilize syngas to produce various essential chemicals.

- Power Generation

Syngas fuels power generation in gas turbines. The efficient burning of syngas produces electricity to power homes and industries.

- Transport Fuels

In the transport industry, syngas provides a sustainable solution. The conversion of syngas into synthetic fuels supports the transportation sector.

- Heating Applications

For heating applications, syngas provides an efficient fuel. It heats homes and industrial premises effectively.

- Fertilizer Production

In fertilizer production, syngas serves as a raw material. Syngas components, mainly hydrogen and carbon dioxide, contribute to the production of ammonia, a crucial ingredient in fertilizers.

- Hydrogen Production

For hydrogen production, syngas serves as the primary source. Through steam reforming, syngas provides hydrogen for various applications.

- Methanol Production

Methanol production relies heavily on syngas. Carbon monoxide and hydrogen in syngas react to form methanol.

- Synthetic Diesel

Syngas can convert into synthetic diesel. The produced diesel is an eco-friendly fuel.

- Waste Management

Waste management utilizes syngas. Organic waste materials undergo gasification, reducing waste and producing syngas.

- Carbon Capture

In carbon capture, syngas plays a pivotal role. Carbon dioxide in syngas undergoes capture and storage, reducing environmental impacts.

Connection Between Biomass Gasification and Syngas!

- Carbon Neutral Process

Biomass gasification converts organic material into syngas. The gasification process ensures a carbon-neutral cycle as plants absorb carbon dioxide during growth, offsetting the emissions from syngas combustion.

- Efficient Energy Conversion

The gasification method allows for more efficient energy conversion compared to direct combustion. Biomass gasification breaks down the organic material into basic elements, producing syngas, a flexible and high-energy fuel.

- Waste Reduction

Biomass gasification transforms waste materials into syngas. Therefore, biomass waste doesn’t just decompose and generate greenhouse gases, but becomes a source of renewable energy.

- Renewable Energy Source

Syngas, produced by biomass gasification, is a renewable energy source. Using plant waste, forest residues, or energy crops provides a sustainable alternative to fossil fuels.

- Chemical Feedstock Production

Biomass gasification turns organic matter into syngas, a vital chemical feedstock. Syngas is used in creating various chemicals, including methanol and ammonia.

- Emission Control

Gasification can regulate harmful emissions. Clean syngas results from scrubbing and cleaning the gas post-production, reducing harmful emissions.

- Biofuel Production

Biomass gasification allows for biofuel production. Syngas can be converted into biofuels like ethanol, a renewable substitute for gasoline.

- Circular Economy

By using waste for energy production through gasification, a circular economy model is promoted. It emphasizes waste as a resource, fostering sustainability.

- Greenhouse Gas Mitigation

Biomass gasification aids in mitigating greenhouse gases. Converting biomass into syngas traps the carbon within the biomass, thus reducing CO2 emissions.

- Sustainability

Biomass gasification is a sustainable energy solution. Producing syngas from biomass provides a low-emission energy source, contributing to global sustainability.

Importance of Syngas Analysis in Biomass Gasification!

- Process Optimization

Syngas analysis improves the gasification process. By identifying gas composition and heat values, operators can optimize conditions for better syngas production.

- Emission Control

Syngas analysis aids in controlling emissions. Knowing the syngas composition helps to reduce pollutants and comply with emission standards.

- Efficiency Evaluation

Analysis of syngas ensures efficient energy conversion. Determining the energy content in syngas verifies the gasification process’s efficiency.

- Quality Assurance

Analysis assures the quality of syngas. Confirming the lack of contaminants in syngas assures its readiness for further processing or use.

- Feedstock Characterization

Feedstock characterization is a critical aspect of syngas analysis. Knowing feedstock properties informs how gasification parameters should be adjusted.

- Energy Content Analysis

Syngas analysis includes determining the energy content. The higher the energy content, the more efficient the fuel will be.

- Contaminant Detection

Syngas analysis detects contaminants. Early detection allows for corrective measures, ensuring clean syngas production.

- Safety Measures

Analysis enhances safety. Identifying any harmful compounds in syngas helps in taking necessary safety measures.

- Environmental Compliance

Syngas analysis ensures environmental compliance. Ensuring low pollutant levels helps meet environmental regulations.

- Techno-economic Analysis

Syngas analysis informs techno-economic evaluation. The value of syngas as an energy source is determined by analyzing its cost, performance, and environmental impact.

Benefits of Biomass Gasification!

- Waste Management

Biomass gasification has a role in managing waste. Unused plant matter, agricultural waste, even trash gets converted into energy. There’s no need for landfill sites, lessening pollution.

- Carbon Neutral

Biomass gasification has a role in reducing carbon footprint. Plants absorb carbon dioxide during growth. Upon burning, the same amount gets released. Hence, no net addition of carbon occurs in the atmosphere.

- Renewable Energy

Biomass gasification contributes to renewable energy production. As plants keep growing, a continual energy source is available. The need for fossil fuels lessens, fostering energy sustainability.

- Reducing Deforestation

Biomass gasification uses waste products, not trees. Thus, the reduction in the need for wood as fuel decreases deforestation rates. It contributes to global forest conservation efforts.

- Rural Development

Biomass gasification fosters rural development. Rural areas often have an abundance of waste material. They can use this resource to generate power, fostering local economic growth.

- Diversified Energy Mix

Biomass gasification adds diversity to the energy mix. It gives an option besides coal, oil, and gas. This diversity strengthens the overall energy system.

- Energy Security

Biomass gasification offers energy security. Unlike fossil fuels, biomass is local. Countries can become less reliant on foreign fuel supplies, increasing their energy security.

- Local Job Creation

Biomass gasification creates jobs. It needs people to collect biomass, run the gasification plants, and manage the system. Hence, it fosters employment opportunities.

- Low Emissions

Biomass gasification results in low emissions. Compared to burning fossil fuels, biomass emits fewer pollutants. It contributes to healthier air quality.

- Resource Efficiency

Biomass gasification uses resources effectively. It transforms waste materials into energy, optimizing the use of available resources.

Benefits of Syngas Analysis in Biomass Gasification!

Improved Efficiency – Syngas analysis improves the efficiency of biomass gasification. Through exact measurements of gas compositions, optimal operating conditions can be achieved, leading to enhanced system performance.

Quality Control – A well-managed syngas analysis system ensures a consistent, high-quality end product. By monitoring gas composition, irregularities are detected and corrected swiftly.

Environmental Compliance – Complying with environmental regulations is critical. An effective syngas analysis helps meet the standards by monitoring and controlling harmful emissions.

Safety Measures – Safety is paramount. Syngas analysis tools monitor the gas composition, detecting harmful gases like carbon monoxide. This ensures a safe working environment for all.

Emission Reduction – Syngas analysis enables emission reduction by ensuring the gasifier operates at optimal conditions. Lower emissions mean lesser environmental impact.

Optimal Gas Composition – Through syngas analysis, the perfect gas mixture for efficient biomass gasification can be achieved, enhancing the overall output.

Feedstock Assessment – Syngas analysis allows an evaluation of feedstock’s suitability for gasification, leading to improved resource management.

Process Control – With syngas analysis, real-time control of the gasification process is possible. Changes can be made on-the-fly, ensuring smooth operations.

Waste Reduction – Waste minimization is a key benefit of syngas analysis. By optimizing the gasification process, less waste is generated, saving resources.

Techno-economic Viability – Syngas analysis ensures the techno-economic viability of the biomass gasification process, leading to a more cost-effective, profitable operation.

Syngas Analysis Techniques in Biomass Gasification!

Gas Chromatography (GC)

One common method for syngas analysis is GC. Filled with gases at different temperatures, GC separates gas molecules for easy study.

- Mass Spectrometry (MS)

Another useful tool, MS helps determine the types of molecules in syngas. By breaking down molecules, MS gives vital information about the gas components.

- Fourier Transform Infrared (FTIR)

To understand syngas components better, FTIR is used. Measuring infrared light absorbed by the gas, FTIR provides a detailed report.

- Flame Ionization Detection (FID)

FID proves essential in detecting carbon-based compounds in syngas. Heat ignites the gas sample, with the resulting ions providing insight.

- Thermal Conductivity Detector (TCD)

For precise temperature measurements, TCD is used. The heat conduction rate in the gas offers important data for analysis.

- Carbon Isotope Analysis

To understand the carbon content, experts rely on this method. Detailed information on carbon isotopes aids in syngas analysis.

- NDIR Spectroscopy

Another method for identifying gas compounds is NDIR spectroscopy. The absorption of infrared light gives detailed data on the gas components.

- TDLAS

Useful for detecting specific gas types, TDLAS uses laser absorption for accurate analysis.

- Process Simulation

To predict syngas properties, process simulation is implemented. By simulating conditions, experts gain a deep understanding of syngas behavior.

- Elemental Analysis

For a detailed look at all components, elemental analysis is the final step. Every single element in the syngas is identified and quantified.

Quality Control in Syngas Analysis!

- Calibration Standards

Maintaining high standards starts with calibration. Regular calibration ensures instruments provide accurate and consistent data.

- Sample Handling

Proper handling of gas samples is crucial. Any contamination can skew results, making accurate analysis impossible.

- Data Validation

Before accepting any results, data validation is necessary. By checking results against expected outcomes, analysts ensure accuracy.

- Instrument Maintenance

Quality control includes instrument upkeep. Regular maintenance ensures instruments stay in optimal condition.

- Quality Assurance Protocols

Following set protocols ensures high-quality results. Adherence to these guidelines maintains data integrity.

- Cross-validation Techniques

By using different methods to analyze the same data, analysts confirm accuracy. These cross-checks maintain high standards of data reliability.

- Auditing Processes

Regular audits of the processes involved help maintain standards. These checks ensure every step follows the correct protocols.

- SOP Compliance

Adherence to Standard Operating Procedures (SOPs) ensures consistency. Following SOPs ensures every analysis is conducted similarly.

- Precision Measurements

Accurate results depend on precision. Each measurement needs to be exact, ensuring reliable results.

- Detection Limits

Understanding the limits of detection is crucial. Knowing what each instrument can and cannot detect helps maintain quality.

Conclusion

Now, you’ve unraveled the intricacies of Syngas Analysis in Biomass Gasification Applications. You understand the benefits, importance, and methods involved. Your next step is to explore more. Find out about the potential of this fascinating field. Visit ESEGAS syngas analyzer. Harness the power of syngas analysis today. The future of energy awaits.