Welcome! You’ll learn a lot about UV-DOAS Gas Sensors here. Your journey will start with basic UV-DOAS technology. Next, understand its components and types of gases it can detect.

You’ll also dive into how it calibrates, and its limits. Compare it with other gas sensors too. Finally, explore how it manages data. Now, start your exciting, enlightening journey!

Basic Understanding of UV-DOAS Technology!

Definition And Conceptual Understanding

UV-DOAS, or Ultraviolet Differential Optical Absorption Spectroscopy, is an advanced sensing method. In pollution control, environmental analysis, and industrial monitoring, you’ll find UV-DOAS . The tech analyzes gas by measuring UV light absorb tion.

As gas-specific, it allows for reliable identification. Unlike other methods, it can pinpoint several gases simultaneously. UV-DOAS is invaluable for accurate, speedy detection, and swift corrective measures.

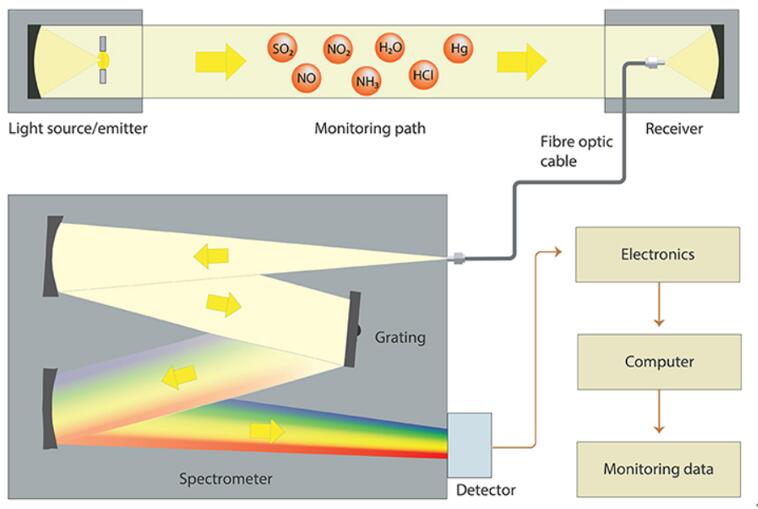

How Uv-Doas Technology Works?

- UV Light Source

At the heart of UV-DOAS is the UV light source. This generates ultraviolet light that goes through the gas sample. Each UV lamp has a specific lifespan, usually thousands of hours. Regular replacement maintains accurate measurements and optimal operation.

- Gas Sample

The gas sample is the subject of the UV-DOAS analysis. During analysis, the UV light shines through the sample. Then, the absorption by the gas molecules occurs. The greater the concentration, the more light the gas absorbs.

- Absorption Process

Absorption is key in UV-DOAS technology. Gases absorb UV light at specific wavelengths. Therefore, by identifying the wavelengths absorbed, you can identify the gas. Notably, each gas has a unique absorption fingerprint.

- Spectroscopic Measurement

Next is the spectroscopic measurement. Here, you determine the quantity of light absorbed. Precise, reliable equipment is essential. Deviations in readings can affect the accuracy of the final result.

- Signal Processing

Signal processing is an essential stage. The system converts the light received into an electrical signal. The more gas present, the stronger the signal. The signal then goes through several stages of amplification and filtering.

- Data Interpretation

Data interpretation comes next. You analyze the signal strength and the corresponding gas concentration. By using specialized software, you derive the type and amount of the gas present.

- Emission Wavelength

The emission wavelength plays a significant role. Each gas absorbs light at a specific wavelength. By identifying this, you can accurately determine the gas present in the sample. Proper calibration of the sensor ensures the accuracy of the measurements.

- Optical Path

In the UV-DOAS gas sensor, light travels along the optical path. Multiple reflections occur, increasing the length of the path. More length allows for greater gas detection.

- Diffraction Grating

Next, the diffraction grating comes into play. Acting like a prism, it breaks down light into specific wavelengths. Those wavelengths reveal the type of gas present.

- Photodiode Array

A photodiode array catches these wavelengths. It converts light into electric current. The current then becomes a digital signal for analysis.

- Optical Fiber

The light from the sensor moves through an optical fiber. This fiber ensures a safe passage for the light towards the diffraction grating.

- Differential Algorithm

A differential algorithm analyzes the digital signal. It removes any noise and identifies the gas detected by the sensor.

- Noise Reduction

Noise reduction is a vital step in UV-DOAS gas sensors. It helps in getting rid of unwanted signals, improving the accuracy of detection.

- Calibration Function

Calibration ensures the UV-DOAS gas sensor functions correctly. Regular calibration maintains its precision and ensures reliable results.

- Reference Spectrum

A reference spectrum is used to compare the detected signals. It helps to pinpoint the type of gas and its concentration.

| Steps in UV-DOAS Technology | Description | Key Components | Role in Process | Measurement Parameters | Result |

| UV Light Source | Emission of UV light | Emission Wavelength | Initiate the process | Wavelength | UV light source |

| Gas Sample | Passage of UV light through the gas | Gas Sample, Optical Path | Absorption of UV light | Gas concentration | Absorption level |

| Absorption Process | Absorption of specific wavelength | Absorption Process, Optical Fiber | Identification of gas | Absorption intensity | Identified gas |

| Spectroscopic Measurement | Measure the remaining light | Diffraction Grating, Photodiode Array | Measurement step | Light intensity | Spectrum data |

| Signal Processing | Process the measurement signal | Signal Processing, Differential Algorithm, Noise Reduction | Data processing | Signal quality | Processed signal |

| Data Interpretation | Interpretation of the processed signal | Data Interpretation, Calibration Function, Reference Spectrum | Data interpretation | Data quality | Gas concentration |

Fundamental Concepts Behind Uv-Doas

- Beer-Lambert Law

The Beer-Lambert Law is central to UV-DOAS technology. It states that the absorption of light is directly proportional to the concentration of the gas.

- Absorption Cross-Section

The absorption cross-section is a measure of how a gas absorbs light. Each gas has a unique value, aiding in its identification.

- Molecular Interaction

UV-DOAS technology relies on molecular interactions. When UV light interacts with gas molecules, they absorb specific wavelengths, revealing their presence.

- Specific Absorption

Each gas has a unique specific absorption rate. This rate helps identify the type of gas and quantify its concentration in the sample.

- Reference Spectra

In UV-DOAS, known gas patterns or reference spectra offer help. These known patterns help in the identification of unknown gas types. This key step is the backbone of the whole system. Hence, for UV-DOAS gas sensors, having accurate reference spectra is crucial.

- Wavelength Selection

Light waves have different lengths, called wavelengths. For UV-DOAS, picking the right wavelengths matters. Gas types absorb light at specific wavelengths. UV-DOAS sensors use this fact to identify different gases.

- Spectral Fitting

Next comes spectral fitting. Here, the observed spectra get compared with the reference spectra. The comparison helps to figure out the type of gases present. The UV-DOAS sensor can then find the gases that match the observed spectra.

- Gas Concentration

UV-DOAS helps measure gas concentration. As light passes through gas, some of it gets absorbed. By seeing how much light gets absorbed, one can tell the gas concentration.

- Optical Depth

This term relates to the amount of light absorption. A higher optical depth means more light gets absorbed. For UV-DOAS, it’s an important parameter to understand gas absorption levels.

- Integration Time

UV-DOAS uses a process called integration time. It’s the time taken to collect light for measurement. Longer integration time can lead to better results but at the cost of speed.

- Absorption Coefficient

The absorption coefficient is a measure of how much light a gas absorbs. Each gas has a unique absorption coefficient. In UV-DOAS, it’s vital in identifying different gases.

- Optical Density

Another term related to light absorption is optical density. It represents how much light passes through a gas. More absorption means higher optical density.

- Light Intensity

UV-DOAS sensors measure light intensity. The difference in intensity before and after passing through the gas gives valuable data. This change can help determine gas types and concentrations.

- Gas Path Length

In UV-DOAS, the gas path length matters. It’s the distance light travels through the gas. The longer the path, the more chances will be of light absorption.

- Spectrum Deconvolution

The last step in UV-DOAS is spectrum deconvolution. It separates overlapping gas absorption lines. This step makes it easier to identify individual gases.

Components of UV-DOAS Gas Sensors!

- UV Source

Central to any UV-DOAS Gas Sensor, the UV Source creates ultraviolet light. Ultraviolet light is vital for measuring gas composition.

- Sample Cell

Here, the gas sample resides. The light from the UV Source passes through it. Direct contact with the gas ensures accurate measurements.

- Detector

After the UV light passes through the sample cell, the detector receives it. Captured light data plays a key role in the analysis.

- Spectrometer

The spectrometer analyses the light spectrum. It recognizes specific absorption patterns of different gases.

- Optical Components

These direct the path of light through the system. Prisms and lenses are typical optical components.

- Data Acquisition System

Critical data from the detector finds a storage spot in the Data Acquisition System. Here, raw data turns into useful information.

- Fiber Optics

These are essential for transmitting light from the UV Source to the Sample Cell, then to the detector.

- Calibration Unit

To keep the sensor accurate, the Calibration Unit periodically adjusts the system.

- Pressure Sensor

Monitors gas pressure within the sample cell. Accurate gas pressure is crucial for precise gas detection.

Types of Gases Detected by UV-DOAS Gas Sensors!

- Sulfur Dioxide

Often found in volcanic gases and industrial emissions. UV-DOAS Gas Sensor can accurately detect it.

- Nitrogen Dioxide

Mainly produced by burning fossil fuels, it is critical for maintaining air quality.

- Carbon Monoxide

A deadly, odorless gas, its detection saves countless lives.

- Carbon Dioxide

It’s a greenhouse gas that contributes to global warming. Early detection helps in environmental preservation.

- Ammonia

Commonly used in fertilizers and refrigerants. Accurate detection is essential for safety.

- Methane

Methane is a primary component of natural gas. UV-DOAS Gas Sensor can track its levels accurately.

- Ozone

Found in the Earth’s upper atmosphere. Its detection is vital for monitoring air quality.

- Benzene

Benzene is a common industrial chemical. Long-term exposure can be harmful, making detection key.

- Ethylene

Used in the manufacturing of plastics. Monitoring its levels ensures industrial safety.

- Formaldehyde

Found in building materials and several household products. Its detection can prevent health problems.

- Toluene

Used in making paints and adhesives. Its monitoring is essential for health and safety.

- Xylene

Common in printing, rubber, and leather industries, accurate detection aids in maintaining workplace safety.

- Chlorine

Used in water purification. Its excessive exposure can be harmful, making detection important.

Understanding the Spectrum Analysis Process in UV-DOAS Gas Sensors!

- Spectrum Acquisition

A UV-DOAS Gas Sensor collects light spectrum. Each light color corresponds to a specific gas molecule.

- Baseline Correction

An important step, baseline correction eliminates any system error. The sensor’s readings are now more accurate.

- Spectral Decomposition

Decomposition involves splitting the spectrum into its components. Each component corresponds to a specific gas.

- Reference Selection

The sensor compares the spectrum against reference gases. This step determines the type of gas detected.

- Least Squares Fit

This mathematical method improves accuracy. The sensor can now determine the exact concentration of gases.

- Peak Identification

The sensor checks the spectrum peaks. Each peak signifies the presence of a specific gas.

- Wavelength Calibration

Calibration ensures accurate measurements. The sensor now correctly identifies the type and amount of gas.

- Concentration Calculation

The sensor calculates gas concentration. High concentration implies a gas leak.

- Signal-to-Noise Ratio

An essential parameter, signal-to-noise ratio enhances data quality. A high ratio indicates clear signals and better readings.

- Spectral Overlay

The sensor does overlay the decomposed spectrum. Overlay aids in confirming the detected gases.

- Noise Reduction

Noise reduction minimizes errors. The sensor’s readings are now more accurate.

- Absorption Analysis

The sensor studies how light get absorbed. Each gas absorbs light differently, helping in identification.

- Linearity Check

Linearity relates concentration to absorption. A linear relation simplifies concentration calculation.

- Wavelength Accuracy

Accuracy in wavelength ensures correct gas detection. Any error can lead to wrong gas identification.

- Quality Assurance

The sensor undergoes multiple checks. Assurance measures guarantee reliable and accurate data.

Comparison of UV-DOAS Gas Sensors with Other Gas Detection Technologies!

- NDIR Sensors

Compared to UV-DOAS, NDIR gas sensors are less sensitive. They struggle with lower concentration gases.

- Photoionization Detectors

These detectors react quicker than UV-DOAS sensors. Yet, their selectivity is less.

- Catalytic Sensors

Unlike UV-DOAS sensors, catalytic types can get poisoned. Toxic gases impair their performance.

- Electrochemical Sensors

These sensors wear out quicker. UV-DOAS sensors have a longer lifespan.

- Solid-State Sensors

Solid-state sensors require more maintenance. UV-DOAS sensors need less upkeep.

- IR Absorption

UV-DOAS sensors have higher accuracy than IR absorption. They can detect more types of gases.

- Ion Mobility Spectrometry

UV-DOAS sensors outperform in terms of sensitivity. Yet, ion mobility spectrometry has a faster response time.

- Selectivity Comparison

UV-DOAS sensors excel in selectivity. They can identify more gases.

- Sensitivity Comparison

UV-DOAS sensors offer superior sensitivity. They detect gases even at lower concentrations.

- Cost Analysis

UV-DOAS sensors can be costly. But their longer lifespan makes them cost-effective.

- Speed of Response

UV-DOAS sensors respond slower than some types. But their accuracy compensates for the delay.

- Operational Environment

UV-DOAS sensors handle harsh conditions better. They remain reliable even in challenging environments.

- Maintenance Comparison

UV-DOAS sensors need less maintenance. Other sensors may require frequent upkeep.

- Calibration Needs

UV-DOAS sensors need less calibration. Less calibration means fewer disruptions.

- Data Quality

UV-DOAS sensors deliver high-quality data. Their accuracy and sensitivity ensure reliable readings.

Data Management in UV-DOAS Gas Sensors!

Types Of Data Collected By Uv-Doas Gas Sensors

- Concentration Values

UV-DOAS Gas Sensors gather crucial numbers. These include the concentrations of various gases. Experts monitor and interpret these values to assess air quality.

- Spectrum Data

By collecting light spectrum data, the sensor’s optical mechanism ensures precise measurements. Each gas has a unique spectral pattern, allowing identification.

- Time Stamp

Time stamping each data point ensures chronological analysis. The timing of pollutant release and dispersion can be tracked and analyzed.

- Calibration Records

Sensors need routine calibration. The record of these calibrations is kept to maintain accuracy.

- Alarm Events

The sensor system records alarm-triggering events. These records help identify critical incidents affecting gas concentrations.

- System Diagnostics

Diagnostic data gives insights into the system’s health. Regular checks are essential for smooth sensor operation.

- Equipment Status

The status of every sensor part is continuously monitored. This is vital to spot potential failures before they happen.

- Ambient Conditions

Conditions like temperature, humidity, and pressure are recorded. These factors can influence gas concentration measurements.

- Signal Quality

Quality of the measured signal ensures reliable readings. Regular checks are performed to maintain quality.

- Instrument Errors

Errors in the sensor’s operation are logged. Swift corrective actions are taken upon detection.

- Raw Signal

Sensors collect raw signal data. This raw data is processed to calculate gas concentrations.

- Process Parameters

Parameters like flow rate and pressure within the sensor are monitored. These also pose impact on the sensor performance.

- Maintenance Log

Keeping a record of all maintenance activities aids in ensuring sensor longevity.

- Data Quality

Checks are performed to validate the quality of the collected data.

- Operational Statistics

The sensor’s operational statistics are maintained for reference and analysis.

Data Management And Storage Practices

- Data Backup

Essential data from the sensor is backed up regularly. This ensures no loss of valuable information.

- Secure Storage

All collected data is stored securely. This protects sensitive information from unauthorized access.

- Quality Control

Rigorous control measures maintain data integrity. These controls avoid data corruption.

- Data Validation

Data validation procedures ensure that the collected data is accurate and reliable.

- Data Encryption

Encryption safeguards the data during storage and transfer.

- Time Series Analysis

Data collected over time enables trend analysis. This reveals long-term changes in gas concentrations.

- Regular Updates

Data is updated regularly to reflect current conditions.

- Anomaly Detection

Anomalies in data are identified promptly. Immediate action is taken to rectify issues.

- Data Standardization

Standardization procedures ensure consistency in the collected data.

- Cloud Storage

Data is often stored in the cloud for easy access and increased storage capacity.

- Local Database

A local database offers fast retrieval of data. This is especially useful in real-time monitoring.

- Data Retrieval

Easy retrieval processes enable swift access to the required data.

- Metadata Management

Managing metadata aids in understanding the context of the collected data.

- Data Accessibility

Accessibility is ensured for authorized users. This aids in effective decision making.

- Data Preservation

Data preservation practices safeguard historical data for future reference.

conclusion

You’ve learned a lot about UV-DOAS Gas Sensors. You discovered how it works, detects gases, and handles data. You also learned about its calibration, limitations, and compared it with other sensors. For more insights, do visit ESEGAS . Continue your journey and become a UV-DOAS Gas Sensor expert.