This article is part of our series “How a Portable FTIR Gas Analyzer Improves Furnace Emissions Testing in Your Laboratory?” In this continuation, we move beyond instrument capability and focus on what truly secures credible data.

What Quality Assurance Steps Are Essential for a Portable FTIR Gas Analyzer?

Reliable furnace emissions data starts with calibration and quality assurance. A portable FTIR gas analyzer may leave the factory with a certified baseline, but laboratories cannot stop there. Vendors perform initial calibration against standard gases under controlled conditions. These values establish a reference point, but they may not fully reflect your furnace exhaust matrix. That is why in-lab verification using matrix-matched calibration gases is critical. By testing against standards that mirror your exhaust composition, the lab confirms that the analyzer’s spectral response holds true in real-world conditions.

Equally important is a structured calibration schedule. A good rule of thumb is to run a full zero and span verification every six months. Between these intervals, labs should perform daily or weekly quick checks. Some instruments support an electronic zero function, which speeds up field routines while flagging drift early. Responsibility for supplying calibration gases usually falls to the laboratory. The vendor provides initial calibration before shipment, but ongoing verification depends on the client’s gas standards. This creates a shared accountability model: the factory sets the baseline, and the lab maintains its integrity over time.

Traceability underpins every measurement. To defend results under audit, labs should build an uncertainty budget. Key elements include: spectral fitting error, sampling bias, temperature stability, and the certified uncertainty of calibration gases. A simple checklist helps: Document which standards were used, the environmental conditions, analyzer status, and the measured deviation from expected values. Over time, this record provides a transparent trail showing how uncertainty was controlled and bounded.

Maintenance also plays a decisive role in sustaining data integrity. Portable FTIR gas analyzers are designed for field use, but servicing may still require shipment back to the manufacturer. This creates a trade-off between flexibility and downtime. A practical approach is to stock a spare parts kit and train at least one operator to handle first-line maintenance, such as filter changes or pump checks. Remote vendor support can cover software or configuration issues, while more complex repairs may still require return to the factory.

With sampling and QA clarified, the next step is integration. The real test is how laboratories weave FTIR calibration and workflows into broader testing programs and procurement decisions.

How Should Labs Manage Workflows and Data with a Portable FTIR Gas Analyzer?

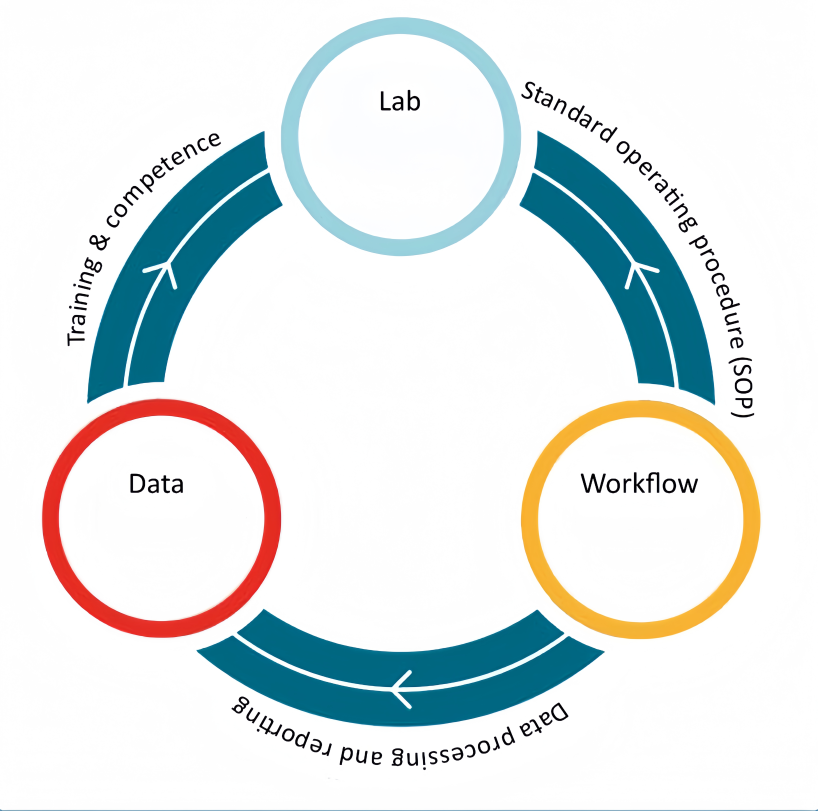

Strong workflows transform a portable FTIR gas analyzer from a measurement tool into a trusted laboratory asset. The starting point is a clear standard operating procedure (SOP). Before any furnace emissions test, the operator should complete a sequence: instrument warm-up, heated line stabilization, leak check, and background spectrum capture. During sampling, the checklist continues with probe insertion, flow control, and documentation of particulate filter changes. After each test, the lab must archive spectra, review baseline stability, and apply QA flags where needed. This structure keeps operations consistent across campaigns and operators.

Next comes data processing and reporting. Every spectrum should be inspected for residuals to confirm that the fitting model is accurate. Automated QA flags highlight drift or poor fits, while limits of detection (LOD) and quantification (LOQ) should be reported alongside concentration values. Reports gain credibility when they also include an uncertainty column, giving end-users context for decision-making. A key practice is to archive raw spectra with time stamps. This allows later reanalysis if regulatory standards evolve or if new compounds of concern are added to the library. Without this archive, valuable insights can be lost.

Finally, laboratories must invest in training and competence building. Although modern FTIR gas analyzers are user-friendly, data integrity depends on operator skill. A short structured training module is the minimum. Labs should also retain at least one local “power user” who manages calibration and troubleshooting. Vendors can support this by offering recorded video sessions and at least two live remote training sessions. With this approach, the lab does not just own an analyzer—it builds in-house capability that safeguards quality.

Sample SOP Outline for Furnace Emissions Testing with a Portable FTIR Gas Analyzer

| Stage | Operator Actions | Purpose |

| Pre-test | Power on analyzer and allow warm-up (≥30 min)Heat transfer line and probe to 180–200℃Perform leak check on all jointsRecord background spectrum | Stabilize system, confirm integrity, and capture baseline |

| Sampling | Insert probe into furnace exhaust sampling portAdjust flow rate to recommended levelMonitor and log filter conditionRecord start time and operator ID | Ensure consistent sample delivery and track filter loading |

| Post-test | Stop sampling and purge lines with clean gasArchive spectra with date and time stampsInspect baseline drift and spectral residualsApply QA/QC flags where needed | Secure raw data for traceability and flag anomalies early |

By embedding SOP discipline, rigorous data practices, and trained operators, laboratories ensure that portable FTIR testing becomes a repeatable, defensible process.

How Do You Build a Smart Procurement Strategy for a Portable FTIR Gas Analyzer?

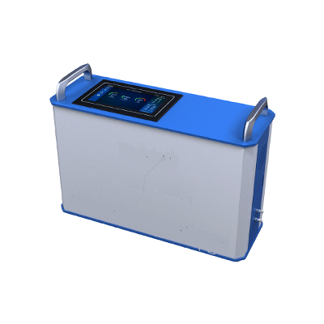

(ESEGAS Portable FTIR Gas Anlayzer ESE-FTIR-100P)

A purchase decision for a portable FTIR gas analyzer should not be rushed. Instead, labs need a clear framework that links daily workflows with long-term operating costs. The right package avoids hidden expenses while ensuring the analyzer fits your lab’s real-world needs.

Use-Case Checklist

Ask the following before signing a purchase order:

- Frequency of tests: daily compliance checks or quarterly R&D campaigns?

- Regulatory drivers: are audits or emission reports mandatory?

- Species list: do you need standard combustion gases only, or rare trace species?

- Moisture/dust severity: can the exhaust overwhelm filters or optics?

- Mobility needs: will you move the analyzer between labs or sites?

This checklist clarifies whether a portable FTIR, a fixed CEMS, or a GC system makes sense.

Cost Buckets to Evaluate

Procurement is more than the instrument price. Consider:

- Analyzer hardware and heated line system

- Calibration gas purchase and shelf life

- Service logistics, including shipping risk if units return to China

- Software library updates for new species

- Spare parts such as filters, pumps, and probes

These costs define the true lifecycle budget.

Recommended Procurement Package

For most labs, a minimum viable package includes:

- ESE-FTIR-100P

- Heated line and probe

- Basic prefilter

- Calibration gas starter kit

- 12-month warranty

If unknown species may appear, add the Premium software library and plan an annual remote review. This ensures flexible measurement capability without locking you into excessive upfront costs.

What Are the Next Steps to Secure Reliable Furnace Testing with a Portable FTIR Gas Analyzer?

Ensuring data integrity in furnace emissions testing requires both the right portable FTIR gas analyzer package and disciplined follow-up. For most labs, the practical path begins with either the Basic or Standard package, backed by a calibration gas starter kit. Acceptance testing should be scheduled as soon as the unit arrives, with a local power-user assigned to oversee operation and verification.

Next, set a clear rhythm: plan six-month verification cycles for zero/span checks, and maintain daily or weekly quick checks. This routine locks in reliable performance while keeping compliance audits stress-free.

The final step is commercial: request a formal pro-forma invoice that includes shipping and taxes. At the same time, decide whether to add an extended spectral library to future-proof your analyzer against unknown species. With these actions, your lab can move from procurement to trusted operation without gaps.

FAQ — Ensuring Data Integrity with a Portable FTIR Gas Analyzer

Q1: Why is factory calibration not enough for furnace exhaust measurements?

A1: Factory calibration provides a baseline under ideal conditions. But real furnace exhaust contains moisture, aerosols, and complex matrices. In-lab verification using matrix-matched standard gases ensures that the spectral response holds in your actual sample conditions. Without that check, systematic bias may go unnoticed.

Q2: How often should I calibrate a portable FTIR gas analyzer?

A2: A full zero and span verification is recommended every six months. In addition, perform quick field checks (daily or weekly) using zero or low-level standards or electronic zero functions. These interim checks help detect instrument drift before it compromises data.

Q3: Who is responsible for providing calibration gases and standards?

A3: The lab or client typically supplies calibration gases for ongoing verification. The vendor covers the factory calibration before shipment. This ensures shared responsibility: the instrument arrives traceable, and the lab maintains traceability over time.

Q4: What goes into an uncertainty budget for FTIR furnace emissions testing?

A4: Key components include:

- Spectral fitting residuals

- Sampling bias (line losses, adsorption)

- Temperature stability in cell and line

- Certified uncertainty of calibration gases

- Flow measurement error

- Repeatability

By documenting each term and combining them (e.g. root-sum-square), you can quantify total uncertainty and defend your results under audit.

Q5: What maintenance and service model should I expect for a portable FTIR?

A5: Portable FTIR gas analyzers offer field flexibility, but complex service may require returning the unit to the manufacturer (e.g. China). To hedge that, keep a spare parts kit (filters, pumps, probe parts) and train a local power-user to perform first-line maintenance (filter changes, pump checks). Leverage remote vendor support for software and configuration issues.

Q6: Is training really necessary if the instrument is “simple to operate”?

A6: Yes. Even a user-friendly instrument can yield flawed data if operators mishandle calibration, sampling protocols, or QA flags. A short formal training module plus ongoing oversight by a local power-user ensures consistency and guards against operator error. Video sessions and remote training reinforce skills.