In a steel mill, standard laboratory-grade sample gas coolers break down quickly. These units work fine in clean labs, but in a mill they stop cooling and clog fast. That failure damages analyzers and eats into budgets.

Steel mills push heat to the limit. Near sinter plants and blast furnaces, air temperatures often exceed 50 °C (122 °F). In that heat, ordinary coolers can’t shed enough energy. They overheat and shut down long before the gas ever reaches safe temperatures. It’s not just hot air. Sample gas in mills carries heavy dust, sticky tar, and corrosive acid vapors. This “dirty gas” coats cooling surfaces and fouls filters. As a result, coolers lose efficiency and clog up far sooner than expected.

When a sample gas cooler fails, trouble follows fast. Hot, wet gas reaches the analyzer, the acid dew point rises, and internal corrosion begins. Analyzers fail, production stops, and environmental monitors report bad data. In many cases, mills face regulatory fines from authorities like the EPA. Each of these challenges proves why steel mills need rugged, purpose-built sample gas coolers rather than off-the-shelf lab units.

Why Does Cooling Steel Mill Gas Matter for Sample Gas Coolers?

What Gases Do We Actually Measure in Steel Mill?

In steel mill emission streams, each process creates a unique mix of combustion gases you must manage before analysis. In sinter plants, exhaust typically contains sulfur dioxide (SO₂), nitrogen oxides (NOx), and high moisture—from 10% up to 15% water vapor. These gases are by-products of coke and iron ore combustion in the sintering process and are common targets for emissions monitoring.

In blast furnace operations, the gas stream looks very different. Blast furnace gas is rich in carbon monoxide (CO), often making up about 25–30% of the volume, along with carbon dioxide (CO₂) and significant nitrogen (N₂) and residual moisture. These are products of the reduction of iron ore and coke combustion in the furnace shaft.

As you cool these streams for extractive analysis, it’s critical to know what you’re cooling. Different pollutants behave very differently when temperature and humidity change.

Why Some Gases Can’t Be Cooled?

Most common combustion gases like CO, CO₂, SO₂, NO, and NO₂ are fine for “cold-dry” sampling after cooling and moisture removal. That’s the focus of this guide because these gases don’t react strongly with water and are usually measured with non-dispersive infrared (NDIR) or chemiluminescence techniques.

However, other species behave differently. Acidic or highly soluble gases such as hydrogen chloride (HCl), hydrogen fluoride (HF), and ammonia (NH₃) will readily dissolve into condensed water if the sample cools below the dew point. For those gases, you must use hot-wet sampling—keep the sample above dew point all the way to the analyzer to avoid loss or chemical change.

What Happens?

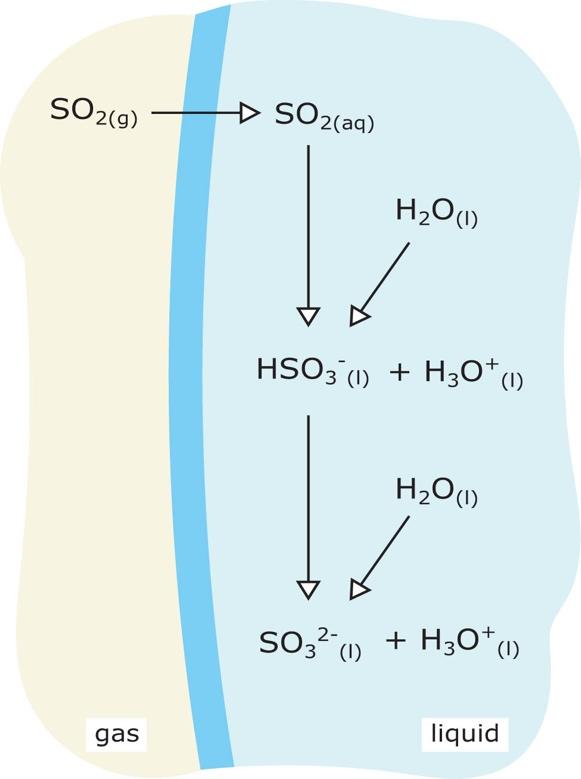

“Washout” Effect— One of the biggest pitfalls of cooling dirty mill gas is the washout phenomenon. SO₂, for example, dissolves easily in condensed water and forms sulfite/bisulfite species in solution. If your sample gas cooler lets liquid water collect or allows the gas to sit in contact with water too long, a large fraction of the SO₂ dissolves out of the gas phase. This means the analyzer may see 50 ppm while the actual stack emissions are 100 ppm—resulting in false compliance.

Acid Mist Formation— Rapid gas cooling without effective water separation can also generate acid mist. As hot flue gas cools, especially when sulfur oxides are present, water vapor and acidic vapors can nucleate into tiny sulfuric acid droplets. These droplets are too fine for standard particulate filters and can pass straight into analyzers, corroding internals and degrading sensors.

Therefore, these effects show why intelligent gas conditioning—beyond simple temperature reduction—is essential in steel mill emission sampling and why off-the-shelf coolers often fall short.

How Do You Choose a Sample Gas Cooler for Different Steel Mill Zones?

Zone A: Sinter Plant — Focus on Corrosion and Accuracy

In the sinter area, exhaust gas has high SO₂ levels and heavy dust loading, creating an extremely corrosive environment. Standard steel coolers and stainless heat exchangers will rapidly fail, especially when acidic condensate forms inside the unit. Instead, choose sample gas coolers with PVDF or glass heat exchangers because these materials resist acid attack and hold up better against dust and corrosive vapors typical in sintering off-gas conditioning.

Next, the unit must separate water and gas quickly. Use cyclone or impingement condensate separation methods to fling condensed water out instantly as it forms. This prevents the sample gas from lingering in water, which can dissolve reactive components like SO₂ and distort analyzer results (the “washout” problem discussed earlier).

In addition, corrosion-resistant materials and rapid condensate rejection keep your gas stream conditioned accurately and protect analyzers from acids and carry-over solids.

Zone B: Blast Furnace / Coke Oven — Safety and Cooling Capacity

In blast furnace and coke oven areas, the priority shifts from corrosion to safety and robustness. These zones often have high carbon monoxide (CO) concentrations, which are toxic and flammable under certain conditions.

For this reason, choose ATEX Zone 1 or Zone 2 certified sample gas coolers when the cooler sits within a hazardous area radius. Certification ensures the cooler and its electrical systems are safe for explosive environments.

Furthermore, these zones can experience temperature spikes from process upsets (tar, soot, and hot gas surges). Standard Peltier coolers may not keep up. Instead, specify high-capacity compressor-based cooling systems that maintain a low dew point even with sudden heat loads and heavy condensate.

By matching cooler design to process conditions, you protect personnel, analyzers, and the integrity of your emissions data — and you reduce downtime from equipment failure.

How Should You Choose Between Compressor and Peltier Sample Gas Coolers in Steel Mills?

(Left: Büler Compressor Sample Gas Cooler; Right: Büler Peltier Sample Gas Cooler)

Why Compressor Coolers Are the Steel Mill Standard

In harsh industrial sites like steel mills, compressor-based sample gas coolers deliver the high cooling capacity you need. These systems use a mechanical refrigeration cycle to move heat out of the gas stream, and they handle large heat loads far better than Peltier elements. They work reliably even when ambient temperatures soar above 50 °C (common near mill gantries and outdoor installations) because the refrigerant cycle can shed heat aggressively under extreme conditions.

For outdoor and high-heat installations, this robust cooling is not optional — it’s mandatory. Compressor coolers maintain low dew point outputs steadily, ensuring your sample gas reaches the analyzer dry and within specification. They also support multiple gas lines and offer stable performance despite heat spikes, making them ideal for complex steel mill emissions systems.

Where Peltier Coolers Can Fit — and Where They Can’t

Peltier (thermoelectric) coolers use a solid-state effect to move heat across a semiconductor junction. These units are compact, vibration-free, and offer fine temperature control in tightly controlled environments, such as indoor lab spaces or climate-controlled shelters.

However, their cooling capacity is limited and depends heavily on ambient temperature. In a shelter where the ambient is kept below ~35 °C, a Peltier cooler can maintain predictable dew points. But if the shelter’s air conditioning fails or the cabinet warms, the Peltier element quickly loses effectiveness. In hot field conditions, it simply cannot keep up with the heat load.

By selecting the right technology for your environment and connecting your sample gas cooler into your control system, you improve uptime and ensure your emissions data remains accurate — even in the toughest steel mill conditions.

What Maintenance & Reliability Features Matter in a Steel Mill Sample Gas Cooler?

“Self-Cleaning” Heat Exchangers for Dusty Conditions

Steel mill sample gas coolers operate in extremely dirty air streams packed with dust and particulate. To stay reliable, choose coolers with smooth, hydrophobic coatings on internal heat exchangers. These surfaces shed condensed water and particles instead of letting them stick and build up. This design helps keep surfaces clean longer and minimizes manual cleaning needs in harsh environments where dust can blind normal exchangers. Reliable coatings improve uptime and reduce maintenance cycles.

Acid-Resistant Peristaltic Pumps for Condensate Handling

When your sample gas cools, water and acid condensate form and must be removed cleanly. Standard pump tubing can degrade quickly in a sinter plant’s acidic condensate. For this reason, use acid-resistant peristaltic pumps with tubing made from materials like Novoprene or Pharmed that can resist chemical attack. These pumps continuously remove condensate without letting liquid sit, protecting your lines and analyzers from corrosion and clogging. This style of pump is essential for sample systems handling heavy condensate loads.

Pre-Cooling for Extreme Hot Inlets

In steel mill sampling, some probe gas temperatures exceed 200 °C before they enter the main cooler. Dropping temperature that fast stresses heat exchangers and pumps and may overwhelm the system. To prevent this, add a pre-cooler probe ahead of the main cooler. The pre-cooler brings down extreme inlet temperatures closer to manageable levels before the gas enters the primary conditioning stage. This staged approach extends cooler life, reduces wear, and ensures stable dew point control under heavy thermal loads — a practical step in rugged field sampling.

Therefore, these maintenance-focused features help your sample gas cooler run longer with fewer downtime events. They reduce manual interventions and improve overall reliability in demanding steel mill environments that beat up equipment without robust design choices.

Conclusion

In steel mill emissions sampling, the right sample gas cooler protects analyzers, saves maintenance time, and keeps your data accurate. Always match the cooler to the process zone and gas characteristics, not only to your budget. A correctly specified cooler ensures reliable dew point control, long life, and fewer compliance headaches.

FAQs:

1. What is a sample gas cooler and why does a steel mill need one?

A sample gas cooler lowers the temperature of extracted flue gas before it reaches analyzers in a CEMS (Continuous Emissions Monitoring System). Cooling removes moisture, protects analyzer sensors from corrosion, and prevents inaccurate readings and compliance issues. Proper gas conditioning is essential for reliable emissions data.

2. What’s the difference between compressor and Peltier sample gas coolers?

Compressor sample gas coolers use mechanical refrigeration to provide high cooling capacity. They work well in high ambient heat (above ~40 °C) common outdoors in steel mill environments. Peltier sample gas coolers use thermoelectric cooling and offer precise control with low vibration, but they perform best in climate-controlled shelters (ambient < ~35 °C).

3. What happens to stack gas when it is cooled in a sample gas cooler?

When hot flue gas enters a sample gas cooler, its temperature drops below the water dew point, causing water vapor to condense out of the gas stream. This condensation removes moisture and reduces gas volume, which helps protect analyzers and stabilizes readings.

As the gas cools, condensed water forms on heat exchanger surfaces and is drained as liquid. If sulfur-containing gases (like SO₂) are present, further cooling can also lead to condensation of acid vapors, such as sulfuric acid, which makes corrosion control important.

Without proper design, condensate can also dissolve soluble gases, leading to inaccurate readings — another reason to manage condensate promptly and avoid extended gas-to-liquid contact.

4.Is ambient temperature regularly over 40 °C?

If yes, choose a compressor-based sample cooler. These units provide superior cooling capacity and stable dew point under high heat — ideal for outdoor or hot mill environments. Compressor coolers handle tough thermal loads better than semiconductor designs.

5. Are you sampling from a sinter plant?

If yes, specify PVDF or glass heat exchangers. These corrosion-resistant materials fight acid and dust, reducing SO₂ wash-out and prolonging service life.

6. Is the cooler located near a blast furnace or coke oven?

If yes, check for ATEX or IECEx hazardous-area certification. Certification ensures safe operation where flammable gases or explosive atmospheres might exist.