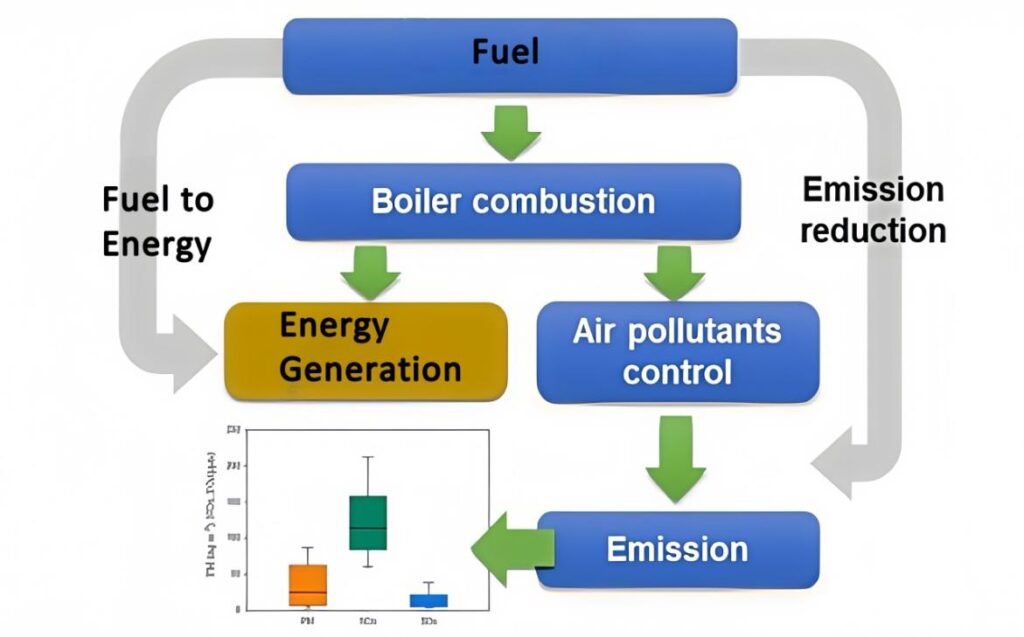

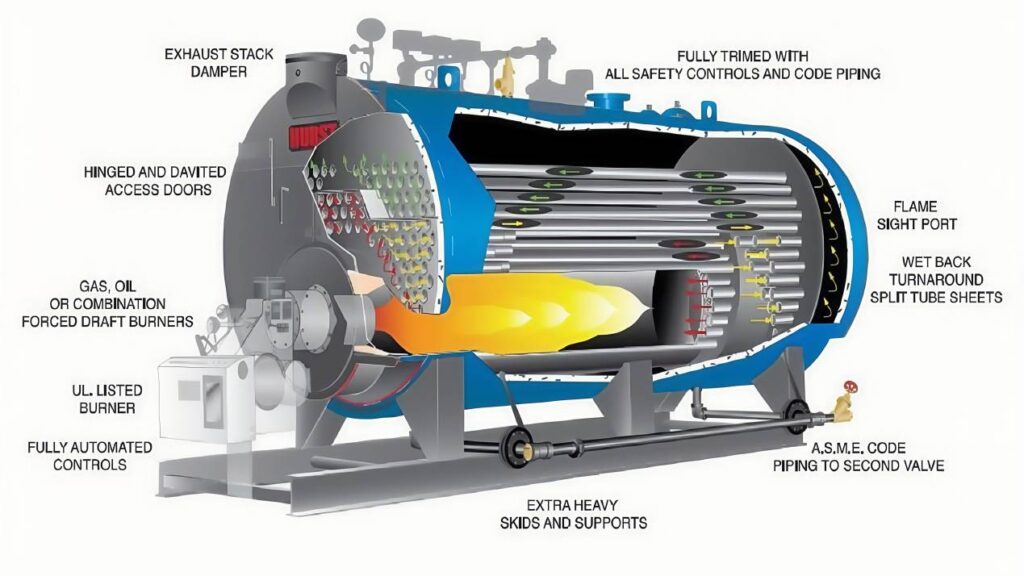

Industrial boilers don’t just burn fuel—they drive energy-hungry operations in power plants, refineries, cement factories, and beyond. To run clean and lean, they need one thing above all: precise oxygen control.

That’s where the zirconia oxygen analyzer comes in. This tool isn’t just another sensor—it’s a real-time decision-maker for combustion. By measuring oxygen concentration right inside the flue gas stream, it gives operators the data they need to fine-tune the air–fuel ratio every second.

The payoff is big: better efficiency, lower emissions, safer operation, and longer equipment life. In the sections below, we’ll break down exactly how zirconia gas analyzer technology works and why it’s a smart investment for modern industrial combustion systems.

Why Does Real-Time Oxygen Monitoring Matter?

1. Why it matters

Combustion is a balancing act. The air–fuel ratio needs to stay in a narrow sweet spot to burn cleanly and efficiently. Even a 1% shift in oxygen concentration can cause heat loss, fuel waste, or a spike in harmful emissions.

A zirconia oxygen analyzer solves this by providing constant, accurate oxygen readings. Unlike manual sampling or intermittent checks, this system works around the clock. It keeps your combustion process on track—automatically, without guesswork.

2. How zirconia gas analyzer technology works

At the heart of the system is a zirconia oxygen probe—a rugged, high-temperature component that mounts directly to the boiler flue. It uses a solid electrolyte made from yttria-stabilized zirconia. When there’s a difference in oxygen pressure between the process gas and the reference air, oxygen ions migrate through the zirconia. This movement creates a voltage signal, which corresponds precisely to the oxygen concentration.

Thanks to this principle, zirconia oxygen analyzers:

- Deliver accurate readings across a wide range: 0.1% to 25% O₂

- Respond in just a few seconds, allowing quick adjustments

- Stay stable even in high-temperature and dusty environments

Meanwhile, the signal directly reflects the oxygen concentration difference between the flue gas and reference air. This allows stable readings at temperatures up to 700–1 200 °C, ideal for boiler and furnace applications

3. What’s the Benefits?

For engineers and control specialists, it means you can:

- Integrate oxygen data directly into your PLC or DCS

- Automate air–fuel ratio control based on live readings

- Minimize manual tuning and unplanned shutdowns

By combining high-speed accuracy and broad dynamic range, zirconia oxygen analyzers bring unmatched control. They let engineers fine-tune boilers in real time, cutting fuel costs while keeping emissions low. And for process-control teams, the data feeds directly into automation, minimizing manual tweaks and human error. The zirconia oxygen sensor transforms your boiler from a reactive system into a precision-controlled, fuel-saving machine.

How Can Zirconia Oxygen Analyzers Help Cut Fuel Costs and Reduce Emissions?

Running a boiler without tight oxygen control is like driving with one foot on the gas and the other on the brake. You burn more than you need—and release more than you should. A zirconia oxygen analyzer helps you find the right balance, and hold it steady, 24/7.

Cut Fuel Waste with Accurate Air–Fuel Ratio Control

The more precisely you control oxygen, the more efficiently your fuel burns. When there’s too much excess air, heat escapes up the stack. When there’s too little, combustion becomes incomplete. Both cost money.

By using a zirconia oxygen analyzer to fine-tune the air–fuel ratio in real time, operators can:

- Reduce unburned fuel loss

- Keep combustion temperature stable

- Avoid flame instability or inefficiency

Over time, even small improvements—just 1–2%—can mean major fuel savings.

Reduce Emissions Without Sacrificing Performance

Fuel efficiency isn’t just about money—it’s also about emissions. Every time a boiler runs rich or lean, it risks producing more CO, NOₓ, and particulate matter.

With zirconia gas analyzer technology, facilities can:

- Maintain optimal burn conditions

- Avoid incomplete combustion and soot buildup

- Lower oxygen content in the flue gas without increasing CO

This not only helps meet environmental standards but also avoids penalties and costly adjustments later.

Fuel costs eat into margins. Emissions limits grow tighter every year. A zirconia oxygen analyzer offers a simple, proven way to solve both problems. It makes your boiler smarter, cleaner, and more profitable—all in one move.

How Do Zirconia Oxygen Analyzers Ensure Boiler Safety and Emission Regulatory Compliance?

Boiler operations aren’t just about performance—they’re about protection. Poor oxygen control can lead to flame instability, carbon monoxide buildup, and unsafe combustion. A zirconia oxygen analyzer helps operators prevent these risks while keeping systems within legal limits.

Keep Combustion Safe and Stable

Combustion safety starts with the right oxygen level. Too little air, and you risk CO buildup or flameouts. Too much air, and the flame weakens or stalls. Neither is safe.

A zirconia oxygen probe constantly monitors flue gas O₂ levels, alerting operators when they drift out of range. This real-time feedback helps teams:

- Avoid incomplete combustion

- Detect leaks or airflow issues

- React quickly to abnormal burner conditions

This is especially critical in high-temperature, high-load environments where reactions happen fast and margins are tight.

Stay Compliant with Emissions Regulations

Global standards for NOₓ, CO, and particulate matter are only getting stricter. Boilers must prove they’re burning clean—and prove it with data.

A zirconia oxygen sensor gives plant managers continuous, verifiable records of oxygen levels. This supports:

- Real-time emissions control

- Permit reporting and audits

- Reduced need for manual sampling or external verification

In many regions, having continuous O₂ data is a legal requirement for large combustion units.

Reduce Risk and Simplify Inspections

No one wants to face shutdowns or fines. A stable, calibrated zirconia gas analyzer reduces the chance of surprise inspections or non-compliance penalties.

A zirconia gas analyzer doesn’t just tweak combustion—it helps maintain a safe, compliant operation under tight regulations. For Plant Engineers, EHS officers, and Project Managers, it provides both protection and peace of mind. Everyone works better knowing the combustion system is under control.

Oxygen monitoring isn’t optional—it’s essential for both safety and compliance. A zirconia oxygen analyzer gives you the tools to stay ahead of both. It catches problems early, provides defensible data, and gives teams the confidence to run tighter, cleaner operations.

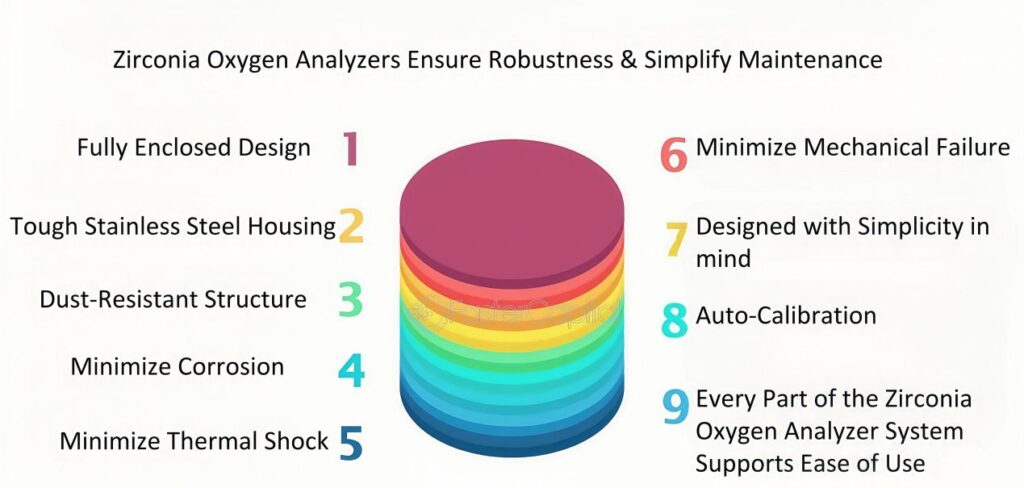

How Do Zirconia Oxygen Analyzers Ensure Robustness & Simplify Maintenance?

Industrial boilers run hot and dirty. Consequently, durability and straightforward maintenance are essential. A zirconia oxygen analyzer thrives in harsh, high-temperature environments. And it cuts maintenance hassle—so engineers, technicians, and OEMs get reliable value.

Built to Survive Harsh, High-Temperature Conditions

Zirconia analyzers thrive in places where most sensors fail. The zirconia oxygen probe operates directly in high-temperature flue gas, often exceeding 600°C. It uses a fully enclosed design, tough stainless steel housing, and a dust-resistant structure to stay functional in dirty, corrosive, and high-load settings.

Its rugged construction minimizes corrosion, thermal shock, and mechanical failure—making it ideal for long-term use in power plants, cement kilns, and incineration boilers.

Maintenance That Fits Into Routine Workflows

The last thing technicians want is a finicky sensor. Fortunately, the zirconia oxygen sensor was designed with simplicity in mind. You can clean the probe with water and vinegar. Routine checks involve inspecting the heater, sealing, and signal drift—tasks that take minutes, not hours.

Plus, ESEGAS’s zirconia oxygen analyzers, ESE-Z-100s, with auto-calibration and built-in diagnostics reduce human error and keep the system running smoothly without constant supervision.

Smart Design That Reduces Downtime

From flanged probe mounts to air-purge options, every part of the zirconia analyzer system supports ease of use. The design:

- Prevents buildup of soot and dust

- Ensures fast replacement when needed

- Integrates easily with DCS or PLC systems

This means fewer unplanned outages and less troubleshooting during critical operations.

Putting in a zirconia gas analyzer means robust performance at high temperatures, easy filter cleaning, and smart diagnostics. Maintenance teams get fewer headaches, control specialists enjoy system stability, and project managers see better uptime and value.

Conclusion

Zirconia oxygen analyzers deliver clear, measurable gains—sharp precision, real-time control, fuel savings, clean emissions, robust operation, and full automation. These analyzers transform boiler performance by offering consistent combustion tuning that reduces operating costs and meets strict compliance goals.

Choosing a zirconia oxygen probe does more than upgrade your measurements. It ensures your combustion system stays reliable for years to come.

You’ll achieve cost savings, cleaner emissions, and a reliable control framework. Do not delay—initiate optimization measures immediately.