How real-time gas analysis can make your DeNOx system more precise and efficient.

Process gas analyzers play a pivotal role in DeNOx system optimization by enabling real-time, accurate monitoring of NOx, O₂, and NH₃ levels—enhancing emissions control, cutting costs, and ensuring regulatory compliance.

Are gas analyzers just measurement tools—or are they essential components of a smart, efficient DeNOx system? Let’s explore how technologies like those from ESEGAS are transforming NOx reduction in power generation.

Why Is Gas Monitoring Critical in DeNOx Systems?

Excessive NOx emissions or ammonia slip? Poor gas monitoring is costing you both compliance and efficiency.

Accurate gas measurement isn’t optional in DeNOx systems like SCR and SNCR—it’s essential. Poor control over key variables leads to emissions violations, catalyst damage, and wasted reagents. Process gas analyzers from ESEGAS offer the precision needed to control these variables in real time.

Here’s why gas monitoring is mission-critical:

- Precise Ammonia Injection Control

Without real-time NOx data, operators often overdose ammonia to ensure compliance—wasting reagent and risking ammonia slip. Gas analyzers detect actual NO and NO₂ levels, enabling just-right dosing.

- Ammonia Slip Prevention

Ammonia slip not only indicates inefficiency but also causes downstream equipment fouling. By monitoring NH₃ directly, ESEGAS analyzers help operators maintain target injection rates without overshooting.

- Dynamic Load Adjustment

Power plant load fluctuates throughout the day. Real-time feedback allows DeNOx systems to adjust ammonia injection dynamically, maintaining consistent NOx reduction regardless of load changes.

- Catalyst Protection and Lifecycle Management

Overdosing ammonia can poison SCR catalysts, shortening their lifespan. Monitoring helps keep reaction conditions within safe limits, protecting expensive catalyst beds.

With advanced, fast-response instruments like those from ESEGAS, power plants can shift from reactive to proactive NOx control, optimizing both performance and cost.

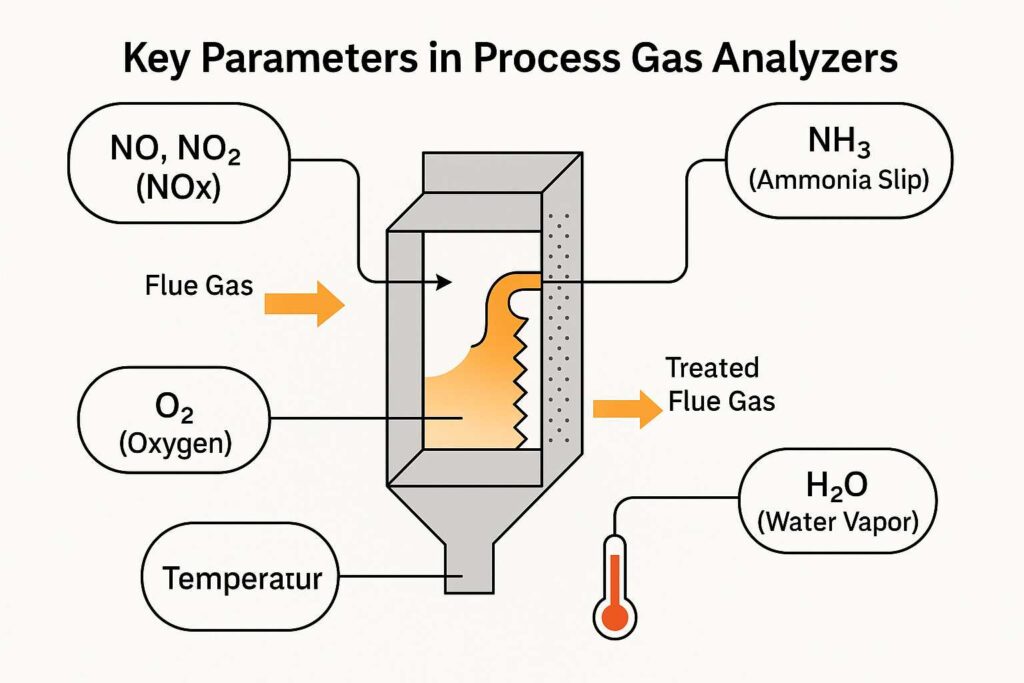

What Key Parameters Do Process Gas Analyzers Measure in Power Plants?

You can’t optimize what you can’t measure—especially in complex DeNOx systems.

Effective NOx reduction requires a clear, real-time understanding of multiple gas-phase variables. Process gas analyzers like those from ESEGAS deliver continuous, accurate measurement of key components that determine system performance.

Here are the most critical parameters:

- NO and NO₂ (NOx)

- NH₃ (Ammonia Slip)

Indicates unreacted ammonia downstream of the catalyst. Monitoring this helps fine-tune injection rates and avoid excess emissions or corrosion issues.

- O₂ (Oxygen)

Essential for combustion control and understanding flue gas composition. Accurate O₂ readings help maintain optimal reaction conditions in both SCR and SNCR systems.

- H₂O (Water Vapor)

Used for correcting dry/wet gas measurement discrepancies and calculating accurate gas concentrations.

- Temperature (via probe integration)

Critical for ensuring the reaction occurs within the ideal thermal window (typically 300–400°C for SCR).

How Do Gas Analyzers Improve Operational Efficiency?

Manual control wastes reagents, energy, and time—automated gas analysis turns guesswork into precision.

DeNOx systems are complex, dynamic processes influenced by load changes, fuel composition, flue gas temperature, and chemical injection rates. Without real-time feedback, operators rely on conservative estimates, leading to inefficiencies. Process gas analyzers, such as those developed by ESEGAS, deliver the intelligence needed to streamline operations and maximize efficiency.

Here’s how gas analyzers significantly enhance operational performance:

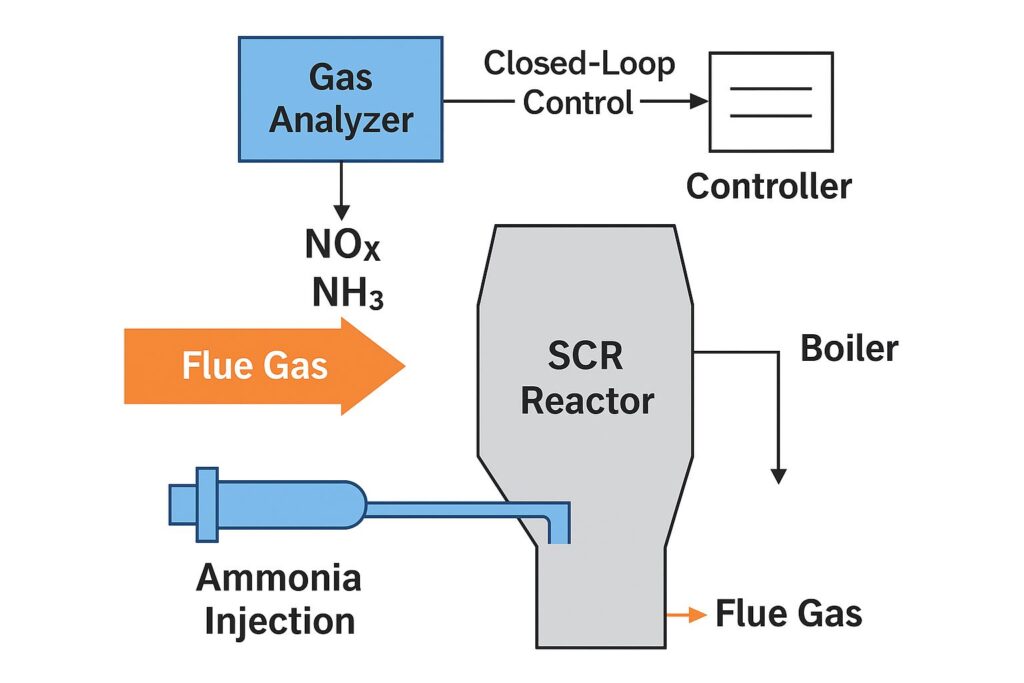

1. Closed-Loop Ammonia Injection Control

Real-time NOx and NH₃ readings enable fully automated feedback loops for ammonia injection systems. Instead of relying on fixed or operator-set injection rates, DeNOx units adjust dosing based on actual flue gas composition—ensuring stoichiometric accuracy and minimizing both under- and over-dosing.

This precision reduces reagent consumption by up to 20% in some SCR systems, directly improving chemical cost efficiency.

2. Energy Efficiency Optimization

Oxygen and temperature measurements help operators maintain combustion conditions and reactor temperatures within optimal ranges. Maintaining SCR reactors at the right temperature (typically 300–400°C) avoids unreacted NOx (when too cold) and ammonia decomposition (when too hot).

3.Catalyst Preservation and Lifecycle Extension

Accurate control of NOx and NH₃ injection directly reduces the risk of catalyst poisoning, especially from ammonia slip. High NH₃ levels can form ammonium bisulfate, a corrosive compound that clogs catalyst pores and damages downstream air preheaters.

By monitoring and minimizing slip, ESEGAS analyzers help extend the catalyst’s functional life and reduce the frequency of expensive regeneration or replacement.

4. Minimized Downtime Through Predictive Maintenance

Gas analyzers offer trend data over time. Drifts in O₂, NH₃, or NOx readings can indicate fouling, sensor wear, or catalyst degradation. This enables predictive maintenance scheduling—preventing unplanned shutdowns and reducing emergency repair costs.

For plants running baseload or flexible load operations, this means more uptime and more predictable maintenance windows.

5.Integrated Plant Control & SCADA Communication

Modern analyzers from ESEGAS are equipped with digital protocols (Modbus, Profibus, OPC-UA) that easily interface with SCADA and DCS systems. This makes gas data part of the plant’s centralized intelligence system, enabling cross-functional optimizations (e.g., tying NOx trends to fuel feed quality or boiler load strategies).

In summary, process gas analyzers transform DeNOx systems from reactive to proactive, inefficient to intelligent. With high-speed, accurate sensing, ESEGAS enables power plants to reduce emissions, save costs, protect assets, and optimize performance across the entire combustion and emission control chain.

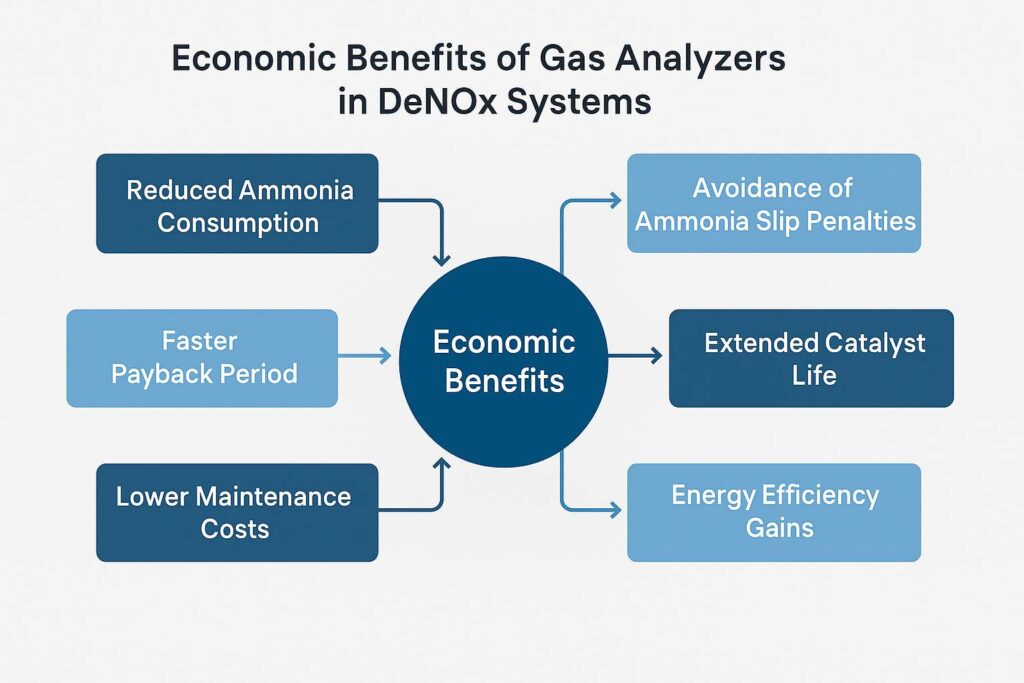

What Are the Economic Benefits of Using Gas Analyzers in DeNOx Systems?

High NOx fines, wasted ammonia, and catalyst degradation—these aren’t just environmental issues, they’re bottom-line threats.

Power plants operating SCR or SNCR systems must strike a balance between stringent emissions limits and operating costs. Gas analyzers offer a clear economic advantage by turning complex combustion chemistry into actionable data. With intelligent sensing from providers like ESEGAS, the financial return is both measurable and compelling.

Here’s how process gas analyzers contribute to cost savings:

1.Reduced Ammonia Consumption

Accurate NOx and NH₃ monitoring enables optimized ammonia injection, cutting reagent use by 10–25% depending on system maturity.

For a mid-sized coal-fired unit, this translates to hundreds of thousands of dollars in annual savings.

By minimizing over-injection, analyzers prevent unnecessary ammonia usage, lowering direct OPEX.

2.Avoidance of Ammonia Slip Penalties

Many jurisdictions impose significant fines for ammonia slip exceeding environmental thresholds. Additionally, excessive slip leads to ammonium salt deposition, increasing cleaning and downtime costs.

Gas analyzers help maintain injection rates within compliant limits, minimizing both regulatory and technical risks.

3.Extended Catalyst Life and Lower Replacement Costs

Catalyst elements are expensive, and degradation due to mismanaged injection leads to premature replacement.

With real-time gas data, operators maintain ideal temperature and reagent balance—protecting catalyst integrity and extending operational cycles by up to 30%.

A single SCR catalyst layer replacement can cost over $500,000—preventing even one premature replacement dramatically improves ROI.

4.Energy Efficiency Gains

By optimizing combustion oxygen levels and SCR operating temperature through O₂ and NOx monitoring, plants reduce excess air heating and unnecessary reheating.

This improves boiler efficiency and cuts auxiliary power demand, which directly impacts net plant output and cost per kWh.

5.Lower Maintenance and Downtime-Related Costs

Uncontrolled ammonia slip causes equipment fouling downstream (e.g., air preheaters), leading to unplanned shutdowns. With accurate analyzers, proactive maintenance can be scheduled before critical failures, improving plant availability.

Every additional percentage point in availability can represent millions in annual generation revenue.

6.Faster Payback Period and Long-Term ROI

The combination of reagent savings, reduced catalyst turnover, fine avoidance, and energy efficiency means that high-performance gas analyzers often pay for themselves within 12–24 months.

Solutions from ESEGAS are engineered for low drift and minimal calibration, further reducing long-term ownership costs.

Ultimately, gas analyzers are not a sunk compliance cost—they’re a strategic asset. With ESEGAS technologies, power plants move from reactive to predictive operations, driving down total cost of emissions control while maximizing system reliability and fiscal return.

Conclusion

Process gas analyzers like those from ESEGAS are not just diagnostic tools—they are operational assets. They improve efficiency, reduce costs, and ensure emissions compliance in DeNOx systems, helping power plants stay competitive and sustainable.

If you have any questions, please contact us.