In every chemical plant, two priorities stand above all else: process control and personnel safety. When either is compromised, production suffers, and lives may be at risk. Unstable reaction conditions can lead to equipment damage or product losses. Undetected gas leaks can cause fire, explosions, or long-term health impacts.

This is where process gas analyzers step in. These instruments don’t just measure gas—they provide a real-time window into the plant’s critical operations. By continuously monitoring key gases like oxygen (O₂), carbon monoxide (CO), hydrogen sulfide (H₂S), or volatile organic compounds (VOCs), etc, gas analyzers:

- Prevent unsafe conditions before they escalate,

- Maintain tight control over reactions and emissions,

- Support automation systems with reliable, high-frequency data,

- And give operators the insights needed to act quickly and confidently.

In this article, we’ll explore the practical side of gas analysis in chemical plants—where it’s needed, how it works, and what value it delivers.

Which Critical Zones in a Chemical Plant Require a Process Gas Analyzer?

There are six priority zones of chemical plant demand steady, reliable gas analysis. Process gas analyzers provide early detection, operational efficiency, and compliance assurance.

1.Reaction Vessels & Catalytic Reactors

In reactors, even slight gas imbalances hurt yield and quality. A process gas analyzer picks up key gases like O₂, CO, and H₂ in real time. This allows tight stoichiometry control, keeping reaction rates optimal. As a result, plants avoid wasted feedstock and off-spec batches. Precise gas tracking also helps anticipate catalyst deactivation—saving costly downtime.

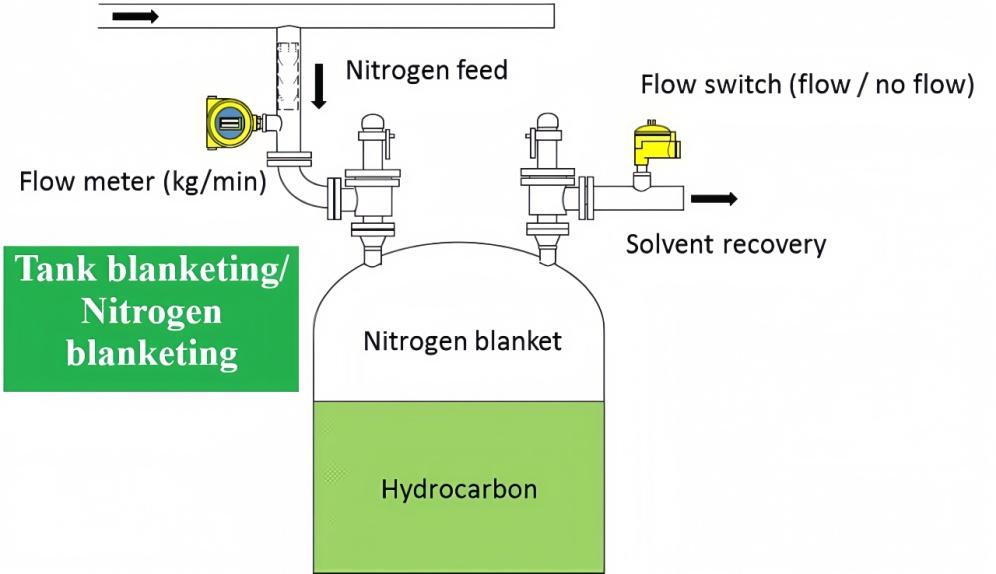

2.Blanket-Gas & Inerting Systems

(Tank Blanketing)

Tanks and pipelines often use nitrogen or argon to keep oxygen low. Without accurate O₂ monitoring, they risk explosive conditions. A process gas analyzer measures O₂ continuously and automatically triggers inert gas flow when needed. This proactive control not only enhances safety but also prevents excessive venting—cutting inert gas costs and emissions.

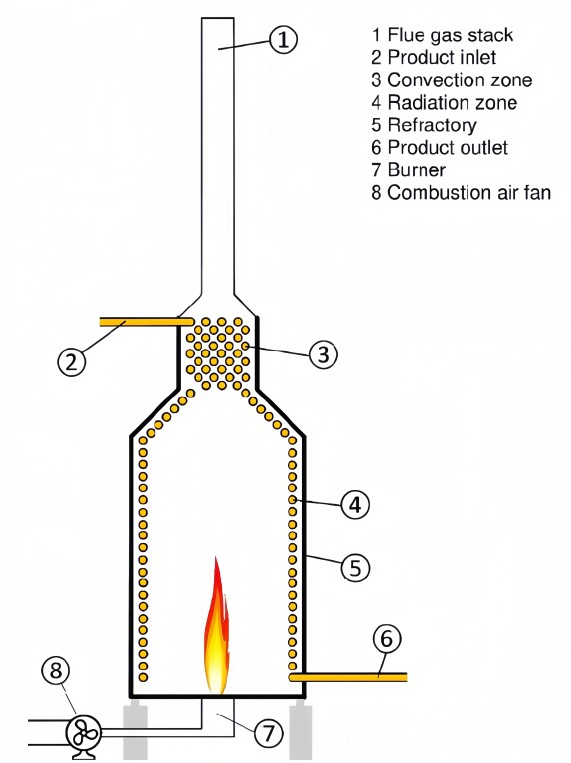

3.Combustion Units & Furnace Exhaust

(Industrial furnace)

Efficient combustion demands the right oxygen ratio. An analyzer measures O₂, CO, and NOₓ in flue gas. With this data, operators can fine-tune burner settings for better fuel efficiency and lower emissions. Importantly, compliance with standards like EPA and OSHA depends on reliable analyzer readings. Thus, process gas analyzers bring both cost savings and regulatory confidence.

4.Confined Spaces / Man-Safe Zones

Confined areas—such as vessels or underground piping—present invisible risks like asphyxiation or poisoning gas pockets. A process gas analyzer provides pre-entry screening and continuous monitoring inside occupied spaces. It watches oxygen levels and detects toxic or flammable gases. If anything shifts, alarms go off instantly, allowing workers to evacuate safely and avoiding serious incidents.

5.Storage Tanks & Pipeline Networks

Ammonia (NH₃), hydrogen sulfide (H₂S), and VOC leaks pose serious health and fire hazards. Placing process gas analyzers around tanks and along pipelines ensures early detection. Spikes trigger alerts and auto-isolation, protecting both personnel and assets. Moreover, this vigilance helps prevent environmental fines and reputational damage.

6.Process Emission Stacks

Stacks emit gas mixtures that must meet environmental regulations. A process gas analyzer can sample exhaust in real time. And it verifies concentrations of CO, NOₓ, SO₂, and more. This ensures continuous compliance and flags deviation trends before they become violations. Plus, collecting and logging this data gives operations teams the insights to optimize processes and reduce emissions over time.

Although these zones may seem diverse, they share a common need for continuous, reliable gas analysis—a need that sets the stage for deeper operational gains. Let’s now explore how analyzers drive process control.

How Does a Process Gas Analyzer Support Process Control in a Chemical Plant?

A process gas analyzer plays a pivotal role in keeping chemical reactions efficient, combustion clean, and systems responsive. It integrates deeply into control strategies, boosting performance and saving costs. Here’s how:

l Real-Time Reaction Management

Process gas analyzers deliver continuous, on-the-spot readings of key gas ratios—like O₂, CO₂, and H₂—inside reactors. With this real-time feedback, operators can:

-Adjust feed rates and catalyst conditions instantly,

-Avoid off-spec batches that cost raw materials and waste time,

-Enhance yield and minimize scrap through tighter reaction control.

These fast insights outpace traditional lab tests, reducing delays and improving throughput

- Combustion & Emission Optimization

In furnaces and boilers, measuring O₂, CO, and NOₓ in flue gas enables:

-Lean but safe burner operation, avoiding inefficient fuel use,

-Reduced formation of CO and NOₓ, cutting both pollution and fuel waste,

-Compliance with emissions rules in real time via continuous emissions monitoring (CEMS).

This meets environmental standards while trimming operating costs.

l Integrating with APC/DCS Systems

Modern Advanced Process Control (APC) systems rely on accurate, live data. When analyzers feed gas composition directly into DCS/APC loops, they can:

-Automatically adjust flows, temperatures, or shut-offs,

-Respond faster than humans can, stabilizing process variability,

-Improve yield, product quality, and energy efficiency significantly—sometimes saving millions annually

This synergy turns gas analyzers into smart controllers that boost plant performance.

l Maintaining Blanket and Lean Air Control

Blanket-gas systems protect tanks and pipelines by maintaining low oxygen levels. Analyzers continuously measure O₂, and when levels climb:

-The system injects inert gas or vents automatically,

-This prevents fire or explosion hazards,

-Plus, it avoids wasted inert gas by responding precisely to setpoints. Such tight inerting control supports safety protocols and reduces consumption

You’ve seen how analyzers sharpen process control—but safety remains equally important. Let’s switch gears and dig into personnel protection.

How Does a Process Gas Analyzer Enhance Personnel Safety in a Chemical Plant?

A process gas analyzer does more than monitor gases—it actively protects people on the front lines. Here’s how it safeguards staff with precision and speed:

1.Immediate Leak Detection

Process gas analyzers constantly scan for toxic gases like H₂S and NH₃, and flammables such as CH₄. Upon detection, they issue tiered alarms—visual, audible, and control-room alerts. This rapid signaling triggers immediate evacuation or ventilation, effectively catching leaks before they escalate into dangerous conditions. Such systems often install in critical zones like pipelines and storage areas for early warning and quick response

2.Confined Space Protection

Before workers enter tanks or vessels, an analyzer verifies O₂ levels and screens for toxic or flammable gases. It then remains active during entry, delivering real-time data directly to safety personnel. This continuous monitoring streamlines compliance with OSHA’s confined-space rules, protects workers proactively, and prevents silent hazards in poorly ventilated environments

3.Failsafe and SIL-Rated Shutdowns

High-integrity analyzers link to Safety Instrumented Systems (SIS) designed under IEC 61508/11 standards. If gas concentrations exceed safe levels, the system auto-triggers shutdowns, inerting, or venting. These SIL-rated setups eliminate human delay, ensuring hazardous conditions never spiral out of control.

4.Remote Monitoring & Diagnostics

Analyzers feed continuous data and event logs to centralized control systems, accessible from safe zones or offsite. This setup cuts unnecessary trips into risky areas while maintaining full visibility of gas levels and device health. Through smart diagnostics, alerts prompt maintenance ahead of failures—saving time and protecting lives.

With both process control and personnel safety reinforced, the next step is figuring out how to bring it all together. Let’s dive into an actionable roadmap for selection and integration.

What’s the Practical Selection & Integration Roadmap for a Process Gas Analyzer?

Bringing a process gas analyzer into your chemical plant isn’t just about buying hardware. You need a thoughtful roadmap—starting with needs and ending with optimization. That’s what this section explores:

a. Define Needs by Zone

First, map out each plant zone—reactors, stacks, tanks, and confined spaces. Then, identify which gases matter (e.g., O₂, CO, H₂S, VOCs) and define their measurement ranges. This clarity ensures your analyzer matches real-world requirements and avoids mis-sizing or wasted features.

b. Choose Sensor Technology

Pick the right sensor for each job:

- Use NDIR/TDLAS for combustibles like CO and CH₄—fast and selective (see TDLAS guide).

- Go with electrochemical or paramagnetic sensors for oxygen. Matching sensor and gas type yields reliable measurements and long service life.

c. Pick In–Situ vs Extractive Configuration

Decide between mounting directly in the process line or sampling gas out:

- In–situ analyzers offer rapid, low-maintenance readings.

- Extractive setups, using probes and conditioning like NeSSI sampling, handle harsh conditions and give flexibility.

Choose based on environment, access, and maintenance needs.

d. Ensure System Integration

Next, integrate instruments into your control architecture. Tie outputs into DCS/APC and Safety Instrumented Systems (SIS). Configure alarms per IEC 62682 for operator clarity. Build intuitive HMI dashboards so crews can see gas trends and take action instantly.

e. Implement Calibration & Maintenance Regimen

Set a regular calibration schedule—ideally 6–12 months—supported by automated diagnostics and contingency testing. Maintain SIL-rated analyzers per IEC 61511 to ensure instrument reliability and safe operation over time

f. Train Field & Control Staff

Don’t skip training. Teach operators how the analyzer works, what alarms mean, and how to respond. Tie protocols into permit-to-work systems and run drills. Well-trained teams prevent panic and ensure safe, smooth operations.

g. Track KPIs & Optimize

Capture data on gas levels, alarms, downtime, calibration, and control performance. Use these insights to:

- Refine alarm setpoints and reduce nuisance alerts.

- Spot anomalies before failures occur.

- Increase analyzer uptime and predictive maintenance.

This cycle turns a tool into a performance driver.

Conclusion

When you structure your process gas analyzer implementation around critical plant zones—like reactors, stacks, and storage tanks—and integrate them into control and safety systems, the gains are multi-fold:

- Ahead-of-curve safety—instant alarms, automatic shutdowns, and worker protection.

- Process excellence—precision control, lower emissions, and energy savings.

- Operational resilience—through disciplined maintenance, analytics, and continuous monitoring.

Start mapping your chemical plant’s zones, define critical gases, choose the right analyzer tech, integrate into control systems, and build a maintenance and training schedule. With this strategy—and sustained monitoring—you’ll transform gas analysis into a strategic engine for safety, efficiency, and long-term resilience.

In short, process gas analyzers don’t just monitor—they actively improve how your chemical plant runs and how safe it is. If you want to know more, contact with us please!