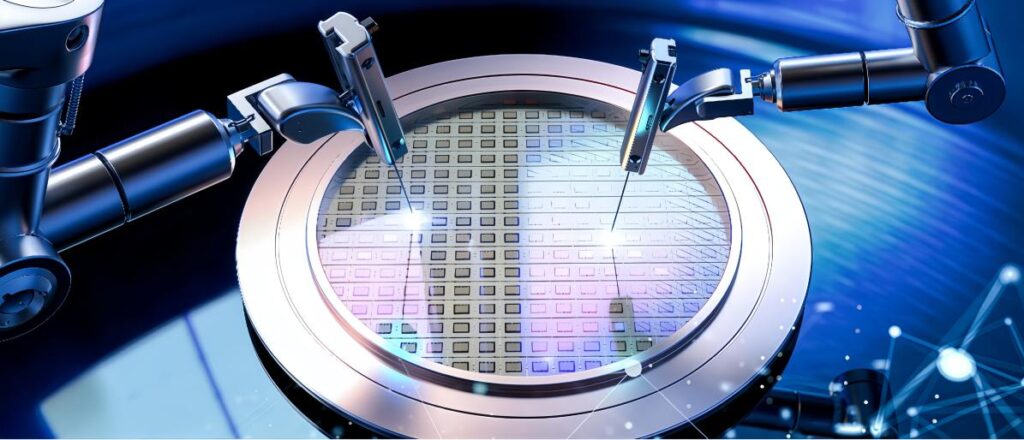

Semiconductor fabrication relies on extremely precise gas mixtures and flows. Tiny changes in gas composition can ruin a chip or reduce yield. An infrared gas analyzer is a high-tech sensor that measures key gas concentrations on-the-fly. In fabs, these analyzers continuously “sniff” gases like hydrogen, carbon monoxide, methane and more. By detecting the exact mix of gases, they give process engineers real-time feedback. This feedback helps adjust flow controls instantly and keeps processes within spec. In this article, we explore what infrared gas analyzers are, how they work, and why they are vital for precision gas control in chip manufacturing.

Why Is an Infrared Gas Analyzer Crucial for Semiconductor Gas Control?

Semiconductor processes demand ultra-pure gases and stable reaction environments. Even tiny gas impurities or flow variations can cause defects. An infrared analyzer gives engineers a real-time window into the gas composition. This continuous monitoring is crucial for several reasons:

- Endpoint detection: In etching, the analyzer watches gas byproducts (e.g. SiF₄) to spot when etching is complete. Stopping at the exact endpoint avoids under- or over-etching, which improves yield.

- Mixture verification: Mass Flow Controllers regulate gas flow by setpoint, but they don’t detect if a leak or calibration error occurs. An IR analyzer double-checks the actual mixture. If a gas flow drifts or a cylinder leaks, the analyzer catches it.

- Safety: Hazardous gases (like H₂ or toxic dopants) must be carefully controlled. An IR analyzer can detect leaks or wrong concentrations early, complementing safety sensors.

- Ultra-high purity: Modern fabs use gases with purity demands in the ppb (parts per billion) range. Advanced IR/FTIR analyzers can detect impurities down to ppb or even ppt levels. This sensitivity ensures contaminants stay within safe limits.

These analyzers act as the eyes of the control system. By feeding back exact concentrations to control loops, they enable “closed-loop” regulation. Engineers can adjust flows, pressures or recipes knowing the actual gas mix. This tight feedback loop is essential for consistent device quality and high throughput. Moreover, regulatory and safety standards require monitoring emissions; IR analyzers help with that too. As a result, fabs often integrate multiple analyzers at gas cabinets, tool inlets, and exhaust points to maintain precision and compliance.

How Can an Infrared Gas Analyzer Measure Gases in Semiconductor Process?

In semiconductor fabs, not all gases absorb infrared light. So, an infrared gas analyzer blends multiple sensing methods. This hybrid design lets it track key process gases precisely. It supports robust control over CO, CO₂, CH₄, and H₂ in real time.

Firstly, the analyzer uses NDIR (Non-Dispersive Infrared) sensing for CO, CO₂, and CH₄. These gases absorb mid-infrared light at specific wavelengths:

- CO₂ absorbs strongly around 4.3 µm.

- CH₄ shows absorption near 3.3 µm.

- CO takes up light close to 4.6 µm.

Optical filters or detectors target these “fingerprint” bands, measuring absorption to compute concentration.

Secondly, hydrogen (H₂) cannot be measured via IR. It lacks a permanent dipole and fails to absorb IR light. So, analyzers use a Thermal Conductivity Detector (TCD) for H₂. The TCD detects changes in thermal conductivity in the gas stream. Since H₂ conducts heat differently, the analyzer infers its concentration. This clever workaround gives accurate H₂ readings.

Thirdly, rather than limiting itself to only those gases, the ESEGAS IR-GAS-600 illustrates how multi-gas analyzers excel. It combines:

- NDIR for CO, CO₂, CH₄ (and optional hydrocarbons CₙHₘ),

- TCD for H₂,

- Optional electrochemical or paramagnetic sensor for O₂,

- N₂ calculated by balance.

This all-in-one module covers nearly every key process gas consistently.

Moreover, the analyzer reports multiple gases at once. That multi-channel capability suits semiconductor processes, which often use mixed gas feeds. For example:

- A CVD step might flow H₂ as carrier and CH₄ as reactant.

- The analyzer delivers those two concentrations in sync.

- If CH₄ dips or H₂ drifts, the control system responds instantly.

Thus, by mixing NDIR with TCD (and O₂ sensing if needed), the analyzer ensures that critical gases — CO, CO₂, CH₄, H₂ — stay within tight specifications. It gives engineers actionable, real-time data to maintain process stability, yield, and safety.

How Do Infrared Gas Analyzers Integrate into Semiconductor Manufacturing Processes?

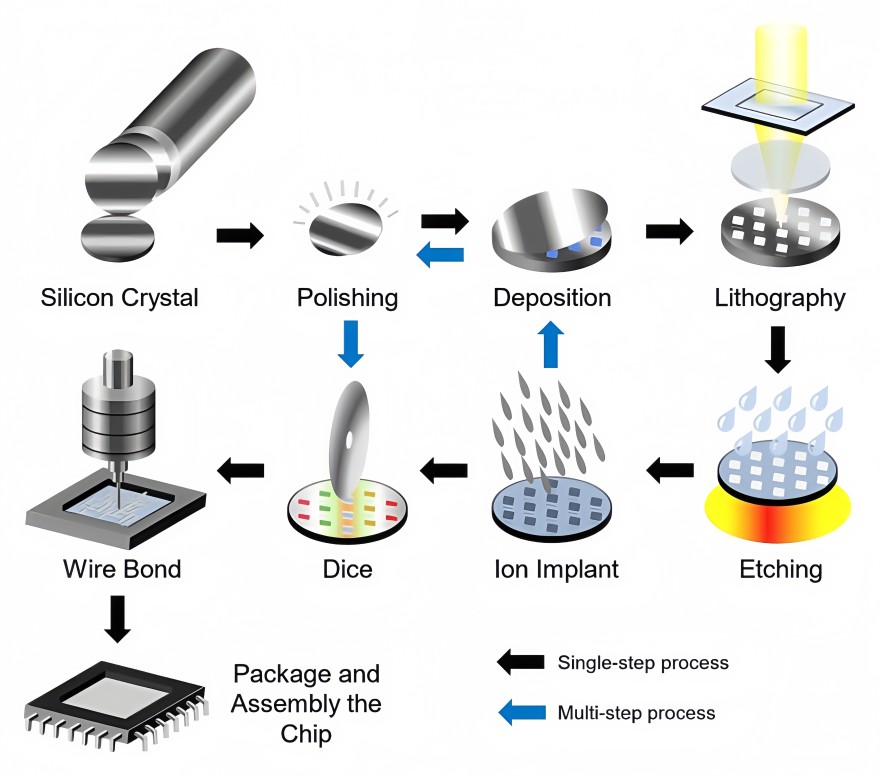

(Semiconductor manufacturing process)

In a fab environment, infrared gas analyzers are integrated at key points to enforce precise control:

- Gas cabinets and lines: Sensitive gate valves and MFCs regulate gas flow to tools. An IR analyzer can be placed at a sampling port on a gas manifold to verify the delivered gas mix matches the setpoint. If a leak or impurity occurs in the cabinet, the analyzer detects it at ppm levels. Safety systems can then shut down affected valves.

- Process chambers: During etch or deposition, an in-line IR or laser analyzer can monitor the exhaust or purge gas. As mentioned, the Horiba LG-100 analyzer tracks SiF₄ in real time to find the etch endpoint. Similarly, a gas analyzer can watch for when reactants are depleted in a CVD chamber, signaling to stop the process. This feedback makes processes adaptive and repeatable.

- Utility gas monitoring: Facility gas systems (like bulk H₂ or NH₃ supply) often include high-purity analyzers. For example, the Thermo MAX-iR FTIR is used to certify ultra-high-purity gases down to ppb impurities. In fabs, even parts-per-trillion contamination can degrade transistor quality. Real-time IR analysis of utility gases ensures purity specs.

- Environmental and emissions control: Cleanrooms and scrubbers must also be monitored. IR analyzers can feed into building management. For instance, a detector could continuously monitor H₂O, NH₃ or HCl in exhaust. If levels rise, process or abatement systems adjust automatically.

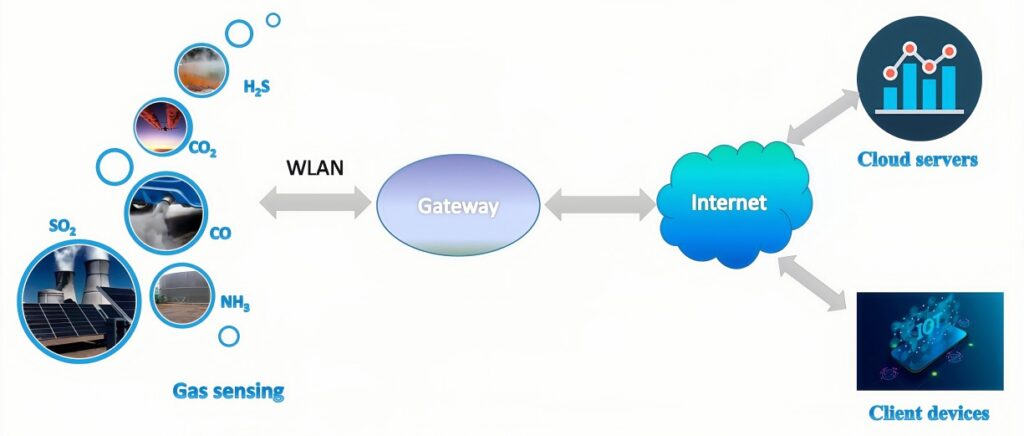

Overall, IR gas analyzers work hand-in-hand with mass flow controllers and process controllers. The MFCs set target flows, and the analyzer confirms actual concentrations downstream. When integrated into the control software (SCADA/DCS), analyzer readings trigger alarms or automated adjustments. The analyzers provide quick feedback – often sub-second response – so control loops stay tight. In practice, fabs install multiple analyzers in a network, each sending data to the central control. This networked approach ensures precision gas control across the plant.

Conclusion

The infrared gas analyzers are like precision “sniffers” in the gas delivery system. They constantly sample and quantify critical gases, enabling engineers to fine-tune flows and recipes on the fly. By combining high sensitivity (ppb-level) with multi-gas detection, they guard both product quality and safety. For semiconductor manufacturing, where the margin for error is microscopic, IR analyzers are essential tools for precision.

If you want to know more, contact with us please!