Environmental monitoring often fails due to inaccurate gas detection, but what if one technology could change that?

Their stability, selectivity, and durability make them ideal for long-term field deployments, supporting environmental compliance and air quality research.

Beyond the precision: why understanding how infrared gas analyzers work is critical to sustainable monitoring solutions.

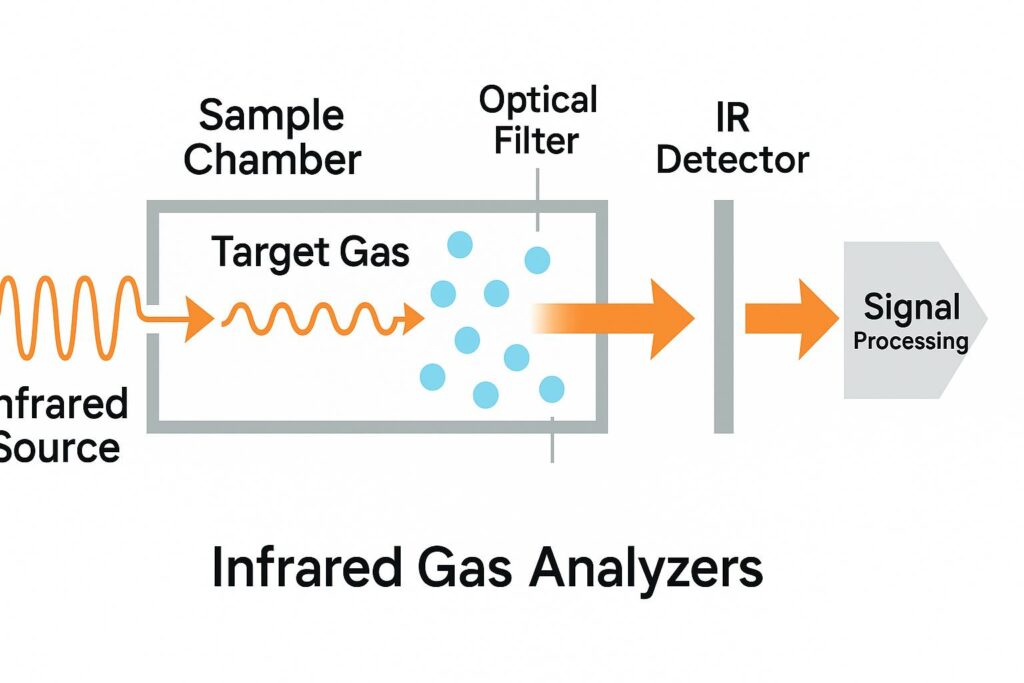

How do Infrared Gas Analyzers Work?

Struggling with fluctuating readings in traditional gas detection methods? There’s a better way.

- Infrared Source: The system contains an IR lamp or emitter that generates a broadband infrared beam. This light passes through a sample chamber containing the target gas.

- Optical Filters: Before reaching the detector, the beam passes through narrowband optical filters. These filters isolate only those wavelengths that are relevant for the gas in question (e.g., 4.26 µm for CO₂). ESEGAS uses high-quality interference filters for maximum selectivity.

- Gas Absorption: If the target gas is present, it will absorb some of the infrared radiation at its characteristic wavelength. The more gas molecules present, the more IR light is absorbed, causing a drop in signal intensity.

- IR Detector: The remaining IR radiation reaches a sensitive detector, such as a thermopile or pyroelectric sensor, which converts the energy into an electrical signal.

- Signal Processing: Advanced signal processing algorithms analyze the detected signal and compute the gas concentration. ESEGAS analyzers integrate digital signal processing (DSP) units that offer temperature compensation, baseline correction, and drift control.

- Reference Channel: Most systems also use a reference channel to correct for environmental factors like temperature, humidity, and optical fouling, ensuring long-term stability and accuracy.

Unlike chemical sensors, this non-dispersive infrared (NDIR) approach is non-invasive, reagent-free, and unaffected by other gases that might otherwise cause cross-sensitivity. This makes it ideal for real-world environmental monitoring, where gas mixtures and ambient conditions constantly vary.

ESEGAS’s engineering innovations—such as gold-coated sample cells for reflectivity, solid-state IR sources for extended lifespan, and modular optics—enable users to benefit from long-term durability, zero-drift operation, and quick startup times, even in remote or harsh settings.

What Advantages Do Infrared Analyzers Offer Over Conventional Methods?

Still relying on outdated techniques that require chemicals, frequent maintenance, and lengthy calibration? There’s a smarter, cleaner way forward.

Infrared gas analyzers, particularly those developed by ESEGAS, outperform conventional gas detection methods on nearly every front—speed, accuracy, stability, maintenance, and environmental safety.

1. Real-Time Detection Without Reagents

Traditional methods such as chemical colorimetry or electrochemical sensors rely on reactive agents that degrade over time and require replacement. These systems are prone to contamination and are often affected by humidity and temperature fluctuations. In contrast, infrared analyzers are optical systems that do not chemically interact with the gas, making them non-consumptive, non-invasive, and maintenance-light.

2. Faster Response and Recovery Time

Whereas chemical methods might take several minutes for a full reading, ESEGAS infrared gas analyzers deliver precise results in seconds. This real-time monitoring capability is essential in dynamic environments such as emission stacks, landfill operations, or urban air quality stations, where gas concentrations can change rapidly.

3. High Selectivity and Stability

Electrochemical sensors often suffer from cross-sensitivity—reacting to multiple gases at once—resulting in unreliable data. By contrast, infrared analyzers use narrowband optical filters that target specific gas absorption wavelengths, enabling high selectivity and accuracy even in complex gas mixtures. ESEGAS further enhances this stability with temperature compensation and signal conditioning algorithms.

4. Longer Operational Life with Minimal Maintenance

Infrared gas analyzers have no moving parts and no reactive components, which means less drift, fewer breakdowns, and lower lifecycle costs. Units from ESEGAS often run continuously for years with minimal calibration, thanks to self-zeroing functions and diagnostic firmware that tracks optical clarity and detector stability.

5. Environmentally Sustainable and Safer

Because infrared analyzers don’t use chemicals, they eliminate the need for hazardous waste disposal and reduce operator exposure to toxic substances. This not only aligns with sustainability goals but also makes them suitable for sensitive applications such as indoor air quality and agricultural monitoring.

6. Easily Integrable With Smart Systems

Modern ESEGAS units come with digital output options (Modbus, Ethernet, 4–20 mA) and can be easily embedded into automated monitoring networks, making them ready for IoT integration, remote diagnostics, and AI-based data analytics.

In short, infrared gas analyzers represent a next-generation solution, offering better performance, lower costs, and higher safety standards compared to conventional technologies. For industries where compliance, accuracy, and uptime are critical, the choice is clear—and ESEGAS leads that innovation.

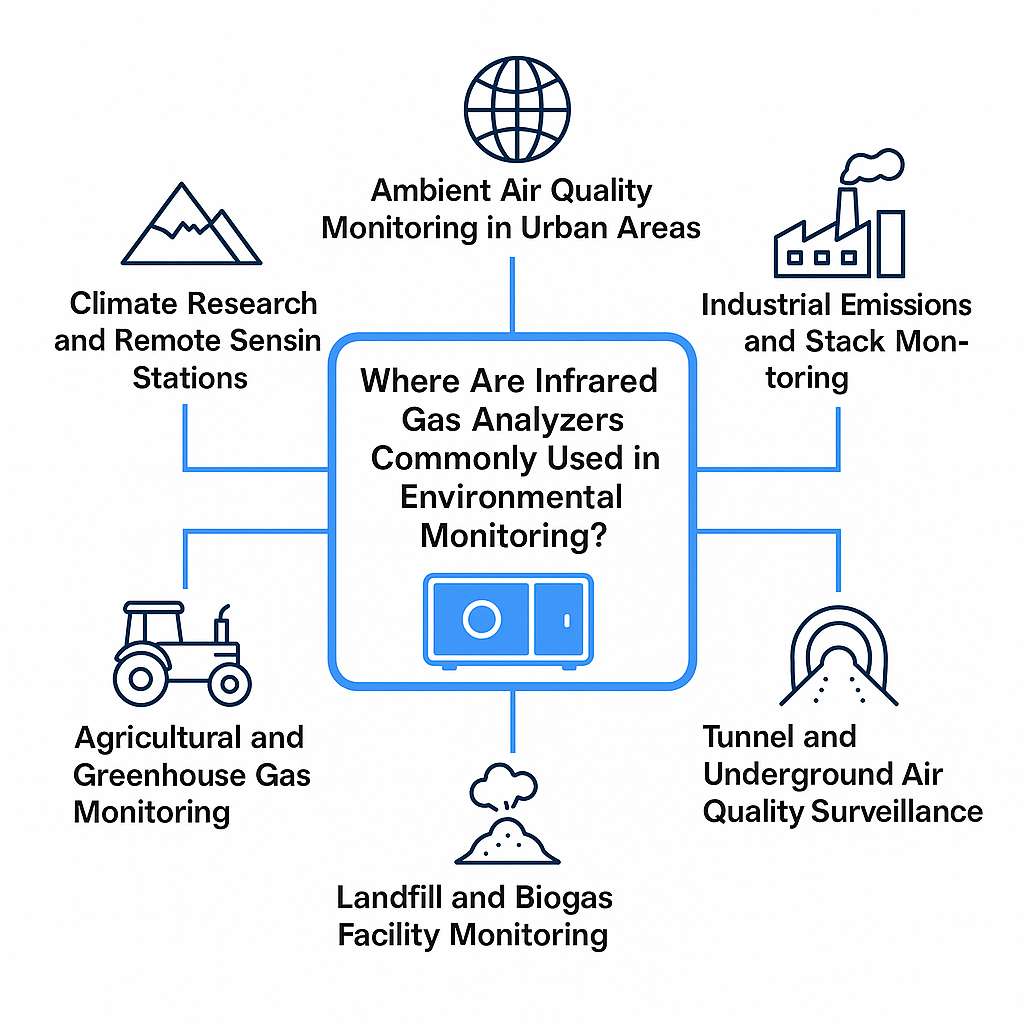

Where are Infrared Gas Analyzers Commonly Used In Environmental Monitoring?

Think infrared analyzers are limited to labs or research facilities? Their role in field monitoring is far more widespread and mission-critical.

Thanks to their precision, durability, and adaptability, infrared gas analyzers have become essential instruments in a wide range of environmental monitoring scenarios. From urban air quality to remote climate research, their non-intrusive detection method offers reliable insights across multiple sectors.

1. Ambient Air Quality Monitoring in Urban Area

Governments and municipalities use infrared gas analyzers to track concentrations of gases like CO₂, NOx, and SO₂in real-time. These measurements are vital for assessing air quality index (AQI) and implementing clean air regulations. ESEGAS analyzers are often integrated into roadside or rooftop sensor stations to provide 24/7 monitoring and issue pollution alerts.

2. Industrial Emissions and Stack Monitoring

Factories, power plants, and incinerators are required to monitor and report their emissions. Infrared analyzers from ESEGAS are commonly installed in Continuous Emissions Monitoring Systems (CEMS) to track pollutants such as CO, CO₂, CH₄, and SO₂. Their rugged enclosures and self-cleaning optics make them ideal for high-temperature and corrosive environments.

3. Agricultural and Greenhouse Gas Monitoring

Infrared technology plays a key role in measuring methane and nitrous oxide emissions from livestock operations, rice paddies, and fertilizer use. These gases contribute significantly to climate change. ESEGAS analyzers are deployed in open-field sensors or drone-mounted modules to assess emissions without disturbing natural processes.

4. Landfill and Biogas Facility Monitoring

Methane leaks from landfills are both an environmental hazard and a resource loss. Infrared analyzers are used to measure CH₄ and CO₂ concentrations around landfill perimeters and gas recovery systems. ESEGAS systems support both point-source detection and diffuse plume tracking, helping operators optimize gas capture efficiency.

5. Climate Research and Remote Sensing Stations

In Arctic tundras, tropical rainforests, or ocean buoys, infrared analyzers collect long-term atmospheric data on greenhouse gases. These records feed into global climate models and IPCC assessments. With features like low power consumption, autonomous operation, and remote telemetry, ESEGAS units are field-proven even in the world’s harshest ecosystems.

6. Tunnel and Underground Air Quality Surveillance

In enclosed infrastructures such as road tunnels, subway systems, and mining shafts, maintaining breathable air is critical. Infrared analyzers detect elevated CO and CO₂ levels caused by engines or decomposing materials, ensuring occupational safety. ESEGAS designs models that operate reliably in low-ventilation, high-humidity environments.

In every application, the common theme is clear: reliable, real-time gas analysis is critical to understanding and protecting the environment. By offering field-tested performance, ESEGAS analyzers help stakeholders—from scientists to regulators to operators—make informed, data-driven decisions with confidence.

What Types Of Gases Can Be Detected With Infrared Technology?

Concerned that your gas detection system may be limited in scope? Infrared analyzers offer unmatched flexibility across a wide spectrum of environmental gases.

Infrared (IR) gas detection is highly versatile, capable of identifying and quantifying dozens of gases that absorb infrared radiation in specific wavelengths. Thanks to the non-dispersive infrared (NDIR) technique, analyzers can be custom-tuned to target a broad range of molecules based on their unique absorption signatures.

Carbon Dioxide (CO₂):One of the most prevalent and critical greenhouse gases, CO₂ is readily detectable due to its strong IR absorption at ~4.26 µm. Infrared analyzers are widely used to track CO₂ emissions in urban air monitoring, combustion systems, greenhouses, and ventilation diagnostics. ESEGAS units provide ppm to percent-level accuracy for both ambient and high-concentration environments.

Methane (CH₄):CH₄ absorbs strongly around 3.31 µm and is a major focus in climate change studies, oil & gas leak detection, and landfill emission control. With IR technology, methane detection is non-invasive, fast, and requires no sample pre-treatment. ESEGAS provides models optimized for both open-path and extractive CH₄ analysis

Carbon Monoxide (CO):As a byproduct of incomplete combustion, CO is toxic and tightly regulated. Its infrared signature at ~4.67 µm makes it easily identifiable by NDIR sensors. CO monitoring is essential in tunnel ventilation systems, industrial furnaces, and vehicle exhaust analysis—areas where ESEGAS analyzers are actively deployed.

Nitrogen Oxides (NO, NO₂ or NOx):Although NO and NO₂ absorb weakly in the infrared range compared to other gases, advanced ESEGAS analyzers can detect them using enhanced-pathlength cells and signal amplification algorithms. This is particularly useful for regulatory emissions testing in power plants and refineries.

Sulfur Dioxide (SO₂):A key contributor to acid rain and industrial pollution, SO₂ is detectable in the IR range and monitored in stack emissions and smelting operations. ESEGAS analyzers are calibrated to precisely measure SO₂even in high-dust or corrosive environments using protective gas sampling modules.

Hydrocarbons (HCs) and Volatile Organic Compounds (VOCs):Infrared technology can also identify a wide range of alkanes, alkenes, alcohols, and other VOCs. These gases are prevalent in petrochemical processing, indoor air quality assessment, and solvent recovery systems. ESEGAS supports multi-wavelength detection for simultaneous monitoring of complex gas mixtures.

Conclusion

Infrared gas analyzers, especially those developed by ESEGAS, are redefining environmental monitoring through precision, durability, and versatility. From detecting harmful emissions to advancing climate research, their contribution to a cleaner future is both vital and measurable.

If you want to know more details, contact with us please!