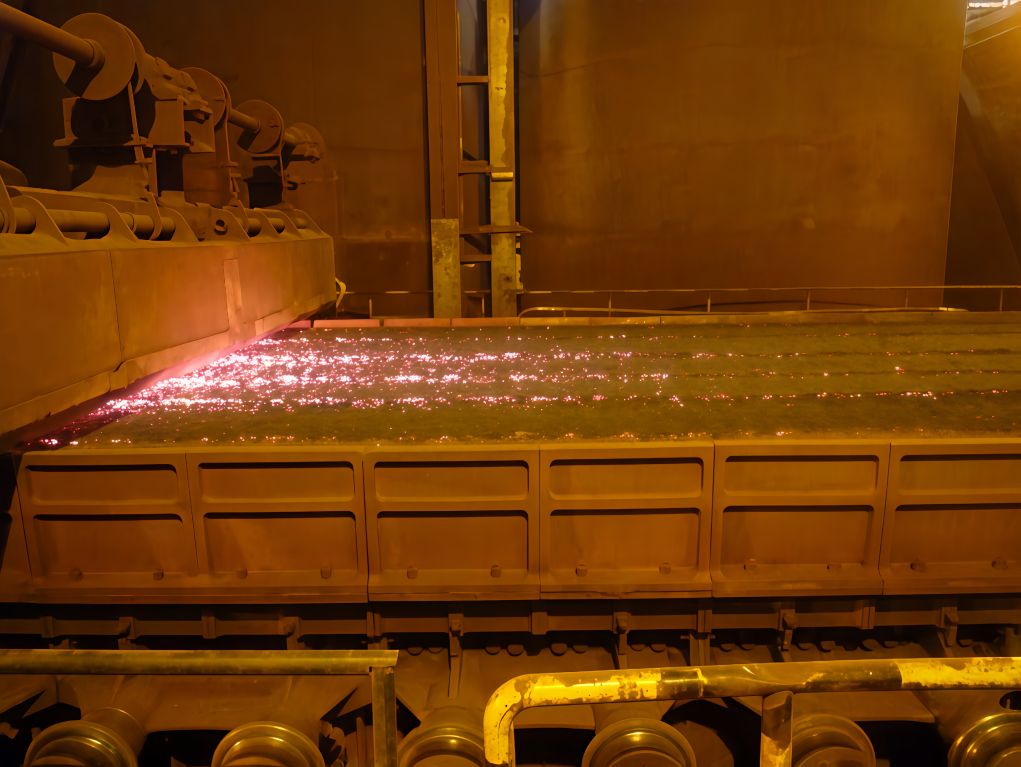

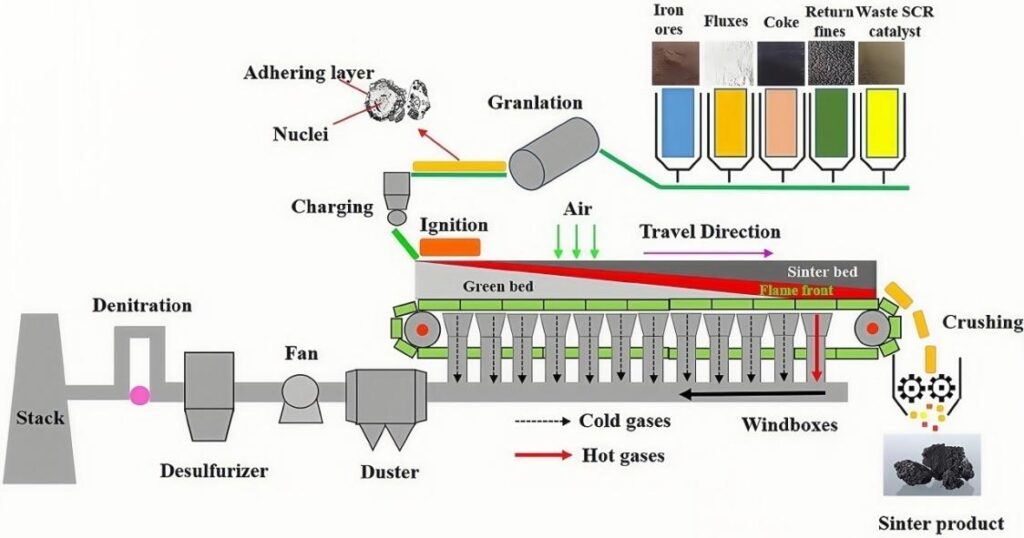

Sintering is a high-temperature (~1200 °C) process that agglomerates fine iron ores, coke breeze, and fluxes into a porous solid (“sinter”) for blast furnace feed. Efficient sintering depends on a uniform fuel burn across the agglomerate bed. In practice, variations in raw mix or bed permeability can spike fuel use: as one report notes, inhomogeneous feed or process fluctuations often increase fuel consumption. At the same time, coke combustion drives emissions. In fact, sintering can account for a large share of a steel mill’s pollutants – roughly 65% of SO₂ and 55% of NOₓ emissions come from the sintering step. Improving fuel-air combustion in the sinter bed is therefore critical both for cutting energy costs and reducing greenhouse gases.

Why Is an Infrared Gas Analyzer Crucial for Optimizing the Sintering Combustion?

Real-time measurement of combustion gases is the key to optimizing the sintering combustion. The infrared gas analyzers are able to provide real-time measurement of O₂, CO, and CO₂. By monitoring O₂, CO, and CO₂ in the sinter exhaust, operators can immediately infer how efficiently the fuel is burning. For instance, rising CO levels indicate incomplete combustion (fuel-rich conditions), signaling that more air is needed. Conversely, high O₂ in the flue gas suggests excess air (lean burn) and waste of heat. Continuous feedback enables automated control: if an infrared gas analyzer detects declining O₂ or increasing CO, it can trigger more airflow or adjust the coke feed accordingly, and vice versa.

Key monitoring actions include:

- Oxygen trim: Maintain a small excess O₂ (typically ~2–4%) in the flue. Too much O₂ wastes energy by heating unnecessary air; too little O₂ leads to CO formation. The IR analyzer’s O₂ channel guides fine adjustment of the combustion air flow.

- CO detection: Elevated CO is a red flag for unburned fuel. If CO is detected, the control system adds air or reduces fuel until CO falls, ensuring more carbon ends up as heat (CO₂) rather than waste.

- Combustion efficiency metric: The ratio CO₂/(CO+CO₂) is a common efficiency index (higher means more complete burn). An IR analyzer provides both CO₂ and CO readings in real time, allowing direct calculation of this ratio for process tuning.

- Automated feedback loop: By feeding analyzer data into a DCS or PLC, the plant can continuously tune the fuel–air ratio. For example, a PID control loop can target a setpoint O₂ or CO₂ level, automatically throttling fans or feeders to hold the combustion at peak efficiency.

These capabilities let the sinter plant ‘tune’ itself: if the analyzer shows O₂ climbing above the setpoint, the system will cut airflow to avoid overdraft. If CO spikes instead, it will add air. Over time, this maintains the highest heat release from each kilogram of coke breeze, minimizing fuel per ton of sinter.

How Does an Infrared Gas Analyzer Work to Monitor Combustion?

Based on non-dispersive infrared technology (NDIR), modern infrared gas analyzers deliver real-time, continuous insight into combustion gas levels. At their heart lies a simple yet effective optical method.

Firstly, an infrared light source shines through a gas sample. As the light travels, specific gases—such as CO₂ or CO—absorb particular wavelengths. For instance, CO₂ strongly absorbs around 4.26 µm, and CO near 4.6–4.7 µm. The remaining light reaches a detector shielded by a narrow filter tuned to those wavelengths—and the detected intensity drops in proportion to the gas concentration. This principle follows the well-known Beer–Lambert law, which ties light attenuation directly to how much gas is in the path.

To compute accurate concentrations, the analyzer compares signals from both a reference channel and the sample channel. That reference usually uses a gas that doesn’t absorb IR—like nitrogen or clean air. The difference helps cancel out drift, aging of components, or interference from other gases.

In many designs, the IR signal is modulated—often using a rotating “chopper”—to distinguish the true gas-absorption signal from background thermal noise.

To sum up, an infrared gas analyzer harnesses light, absorption, and optical finesse to translate invisible gas levels into actionable data. Its clarity, responsiveness, and robustness make it a cornerstone in combustion control systems—especially in challenging industrial settings like sintering plants.

How Can an Infrared Gas Analyzer Help Tune the Fuel–Air Ratio?

Operators aim to strike a balance: just enough excess O₂ (usually 2–4%) ensures burnout without heating excess air. At the same time, maximizing CO₂ relative to CO confirms complete combustion. Modern analyzers react in seconds—so when there’s a drop in O₂ or a spike in CO, the control system corrects instantly. This tight feedback loop—often called “oxygen trim“—has long been standard in boilers. It works just as well for sintering: the plant continuously hovers in its sweet spot between lean and rich combustion.

In industrial combustion systems, “oxygen trim” works as a real-time corrective control loop. A sensor measures excess O₂ in the flue, and the control system adjusts air or fuel flow to maintain the setpoint—optimizing efficiency and reducing CO emissions. Studies suggest that for many boilers, this can reduce fuel use by around 1.5–2%, with payback periods as short as 18 months to three years.

Moreover, precise AFR (air–fuel ratio) control—achieved via continuous flue gas analysis—is essential for peak combustion efficiency and minimal pollutant formation. Tools like CEMS (Continuous Emissions Monitoring Systems) integrate NDIR-based gas analyzers directly into control strategies for industrial combustion

What Makes the ESEGAS IR-GAS-600 Infrared Gas Analyzer Stand Out?

When discussing advanced, industrial-grade infrared gas analyzers, the ESEGAS IR-GAS-600 emerges as a particularly capable and versatile model. Let’s delve into what makes it uniquely powerful for sintering plants—and why it matters on the shop floor.

The IR-GAS-600 shines in its ability to monitor multiple gases at once—even under tough industrial conditions. It houses NDIR (infrared) sensors for CO, CO₂, and CH₄, and adds H₂ measurement via a thermal-conductivity detector (TCD) with automatic compensation for background gases. On top of that, it integrates an O₂ sensor, either electrochemical or optional paramagnetic—delivering a complete gas profile in one streamlined device.

All detectors in the IR-GAS-600 are temperature-controlled or temperature-compensated, ensuring high stability and fast response—even as plant conditions shift. Calibration specs are robust:

- CO, CO₂, CH₄: accuracy within ±2% full-scale, resolution down to 0.001%

- H₂ (TCD): up to ±3%

- O₂ (sensor): similarly precise with fine resolution

This means you can confidently rely on its readings for critical process adjustments.

By bundling multiple sensors into a single unit, the IR-GAS-600 minimizes maintenance needs, reduces footprint, and simplifies installation costs. It’s designed to be placed inline on a sintering plant’s exhaust duct or sampling header, feeding real-time gas profiles into the control system. Operators then gain immediate insight into O₂, CO, and CO₂ trends to stabilize the burn zone before any imbalance escalates.

Table: Comparison of ESEGAS IR-GAS-600 and Typical Single-Gas NDIR Analyzers

| Feature | ESEGAS IR-GAS-600 | Typical Single-Gas IR Analyzer |

| Measured gases | CO, CO₂, CH₄ (optional H₂ via TCD, O₂ via paramag) | Usually one or two (e.g. only CO₂ or CO) |

| Detector technology | Multi-channel NDIR (IR) + optional TCD/ECD for H₂/O₂ | Single-beam NDIR with fixed optical filter |

| Simultaneous output | Yes – all channels read continuously | No – one gas (or channel) at a time |

| Accuracy/Stability | ±2% FS (typical), low drift (temp. stabilized) | ±2–3% FS, often higher drift |

| Measurement range | Very broad (ppm up to 100% span) | Narrower, set for a specific gas range |

| Typical applications | Process/syngas analysis, flue gas monitoring | Single-gas emission monitoring or safety checks |

By combining multiple sensing channels into one cabinet, the IR-GAS-600 is particularly cost-effective for continuous process monitoring. In a sintering plant, it can be installed on the main exhaust duct or in a sampling header from the sinter strand. The analyzer’s readings feed into the sintering machine’s control system, allowing staff to see O₂, CO and CO₂ traces in real time. In practice, this helps stabilize the sinter burn zone: if a hot spot causes O₂ to drop, the control can respond before the fuel mix drifts too far.

What Operational and Environmental Gains Does an Infrared Gas Analyzer Deliver?

Deploying an infrared gas analyzer in a sintering plant yields clear operational advantages. Real-time feedback on combustion means less fuel is needed for the same production output. Plants can typically lower their coke breeze rate by ensuring they only burn as much fuel as required. This cuts operating cost and also reduces CO₂ emissions per ton of sinter. In addition, minimizing incomplete combustion (CO) and unburned hydrocarbons lowers local pollution and helps meet emission limits.

Practically, engineers find that gas-analytics-driven control can improve combustion efficiency by several percent. Over a year, that translates to significant coke savings (worth many thousands in fuel costs) and reduced greenhouse gas output. Consistent combustion also improves sinter quality and stability, since the burn-through layer remains uniform. Finally, safety is enhanced: continuous CO monitoring immediately flags leaks or downdraft in the sintering zone, preventing hazardous buildup.

Conclusion

By providing continuous, precise measurements of O₂, CO and CO₂, an infrared gas analyzer enables sintering plants to finely balance the fuel–air mix in real time. The result is leaner combustion – lower fuel consumption for the same sinter throughput – and a cleaner process with fewer emissions. In other words, infrared gas analysis helps sinter plants run both more efficiently and more cleanly, aligning operational savings with environmental compliance.