Turning Sludge into Energy: Can We Optimize Biogas Production Without Accurate Gas Analysis?

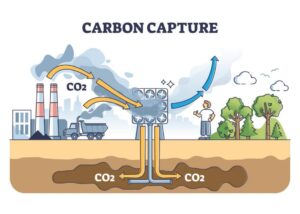

Wastewater treatment plants are increasingly turning to energy recovery solutions to reduce costs and environmental impact. One of the most promising methods is the production of syngas (synthetic gas) through anaerobic digestion of sewage sludge. However, many facilities struggle with optimizing this process due to the lack of precise gas monitoring tools. Without accurate data on gas composition, treatment plants risk energy inefficiencies, safety hazards, and regulatory non-compliance. Syngas analyzers have emerged as a game-changing solution, offering real-time insight and control over the entire waste-to-energy cycle.

Syngas analyzers enhance efficiency, safety, and compliance in wastewater treatment by enabling precise monitoring of gas composition during anaerobic digestion and combustion processes.

More Than Just Clean Water: Why Gas Monitoring Matters in Wastewater Treatment

While wastewater treatment is often associated with purifying water, modern facilities are also focused on generating renewable energy from waste. Anaerobic digestion of sludge produces syngas—a valuable energy source composed mainly of methane (CH₄), carbon monoxide (CO), and hydrogen (H₂). The challenge lies not in producing this gas, but in managing its quality and utility. This is where syngas analyzers play a crucial role, providing the precision needed to transform biogas into a reliable, safe, and efficient energy stream.

What Is the Role of Syngas in Wastewater Treatment Plants?

Unlocking Energy from Waste

In wastewater treatment plants, anaerobic digestion is used to break down organic matter in sewage sludge, producing a mixture of gases collectively known as syngas. This gas typically contains CO, CH₄, H₂, CO₂, and trace amounts of other compounds. Among these, methane holds the highest energy potential and can be used to generate electricity and heat onsite, reducing the facility’s dependence on external power sources. Additionally, hydrogen and carbon monoxide can serve as industrial feedstocks or be utilized in advanced combustion systems.

Why Is It Important to Monitor Syngas Composition in Real Time?

From Risk to Reliability

Without real-time monitoring, wastewater treatment facilities face significant uncertainties in gas quality, leading to inefficiencies and potential hazards. Real-time gas monitoring allows operators to immediately adjust processes to maintain optimal combustion conditions and energy output.

- Energy Optimization: Fluctuations in methane or hydrogen content can impact engine performance. Continuous gas analysis in anaerobic digestion ensures that gas used for energy recovery meets quality standards.

- Environmental Compliance: Accurate flue gas measurement helps control harmful emissions like NOx, CO, and unburned hydrocarbons.

- Safety Assurance: Early detection of abnormal levels of CO and CH₄ prevents dangerous build-ups that could lead to explosions or toxic exposure.

- Operational Efficiency: Automated systems can respond to data from syngas analyzers, improving efficiency and reducing labor costs.

How Do Syngas Analyzers Work in Wastewater Treatment Applications?

The Technology Behind the Measurement

Syngas analyzers use a variety of detection methods to measure gas concentrations:

- Non-Dispersive Infrared (NDIR) for CO, CO₂, and CH₄

- Thermal Conductivity Detector (TCD) for H₂ and inert gases

- Flame Ionization Detector (FID) for hydrocarbons

These devices are typically installed inline, directly sampling gas from digesters or combustion units. Data is transmitted in real time to a centralized control system, enabling continuous oversight and process adjustment. Modern units offer self-calibration, automated cleaning, and data logging, minimizing maintenance efforts while maximizing uptime.

What Are the Benefits of Using Syngas Analyzers in Waste-to-Energy Processes?

Precision That Pays Off

Integrating a gas analyzer for waste-to-energy systems brings multiple benefits:

- Improved Energy Efficiency: Higher-quality biogas leads to more stable and productive energy conversion.

- Enhanced Safety: Continuous CO and CH₄ detection reduces the risk of fire or explosion.

- Regulatory Compliance: Helps facilities meet air quality standards with accurate emission reporting.

- Cost Savings: Early detection of performance issues prevents expensive equipment damage and process downtime.

- Sustainability Goals: Supports the circular economy by transforming waste into renewable energy.

What Factors Should Be Considered When Choosing a Syngas Analyzer for a Wastewater Treatment Plant?

Smart Selection for Smart Operations

When evaluating a syngas analyzer, facilities should consider:

| Criteria | Importance |

| Measurement Range | Must accommodate expected gas concentrations |

| Detection Technologies | Ensure compatibility with target gases |

| Durability & Corrosion Resistance | Critical in harsh gas environments |

| Integration Capabilities | Easy connection with SCADA and DCS systems |

| Maintenance Requirements | Prefer systems with low upkeep and auto-calibration |

Choosing the right analyzer ensures long-term reliability, consistent performance, and ease of operation.

Conclusion: A Clear Path to Cleaner Energy

Syngas analyzers are no longer optional in modern wastewater treatment—they are essential tools for unlocking the full potential of waste-to-energy strategies. By offering precise, real-time insight into gas composition, these devices improve safety, efficiency, and environmental outcomes. As the push for sustainability grows, syngas analyzers will continue to play a pivotal role in transforming waste into a clean, controllable, and renewable energy source.