The Pressure to Produce High-Quality PTT Efficiently—Can Syngas Analyzers Be the Missing Link?

PTT (polytrimethylene terephthalate) production is a chemically intensive process that demands precision and stability. Fluctuations in gas composition, inefficiencies in energy usage, and suboptimal reaction control can lead to inconsistent product quality and increased costs. These challenges often stem from a lack of real-time insights into the syngas (synthetic gas) used during production. But what if there’s a way to monitor and adjust the process dynamically? Syngas gas analyzers could be the game-changing tool that bridges this crucial knowledge gap.

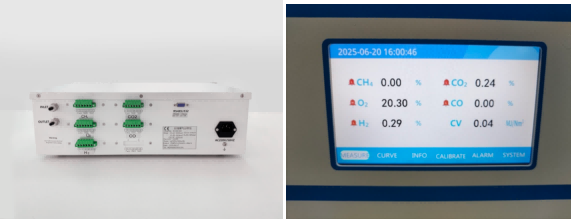

Syngas gas analyzers are vital for real-time control of PTT production processes, ensuring consistent polymer quality, reducing energy waste, and meeting environmental compliance standards. These analyzers measure critical components like CO, H₂, and CO₂, helping manufacturers precisely tune reaction conditions and improve process efficiency.

The Invisible Influencer in PTT Manufacturing

For decision-makers who already understand the role of feedstock in polymer manufacturing, it’s worth diving deeper. How exactly does a syngas gas analyzer integrate into the PTT production line, and what value does it bring at each stage? The deeper we explore, the clearer it becomes—gas analysis isn’t just a diagnostic tool; it’s a production optimizer.

Why Is a Syngas Analyzer Essential in PTT Production?

When Undetected Variability Means Unstable Polymer Chains

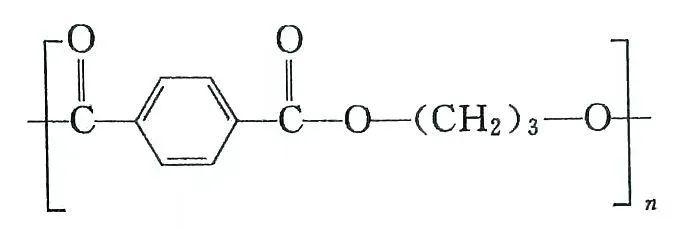

In the production of polytrimethylene terephthalate (PTT), the quality and efficiency of polymer synthesis are intimately tied to the chemical consistency of the feedstock—specifically, syngas. Syngas, typically composed of carbon monoxide (CO), hydrogen (H₂), carbon dioxide (CO₂), and trace impurities, serves as the foundational input for synthesizing 1,3-propanediol (PDO), a core building block of PTT.

Even slight fluctuations in gas ratios can cause significant deviations in conversion rates, reaction kinetics, and final product quality. In a tightly controlled chemical environment, these deviations can lead to unstable molecular weight distributions, yellowing of polymer fibers, or unwanted side products—all of which are unacceptable in high-performance applications like textiles and automotive materials.

A syngas gas analyzer mitigates these risks by providing real-time, continuous analysis of the gas composition at critical points in the process.

How Syngas Analyzers Add Value in the PTT Production Workflow

Here’s how syngas gas analyzers prove essential:

- Feedstock Verification and Consistency

- Before entering the reactor, syngas must meet predefined molar ratios of CO and H₂ (often near 1:2 depending on the pathway).

- Gas analyzers provide immediate feedback on deviations, allowing for inline blending or rejection of off-spec gas.

- Catalyst Protection and Optimization

- Catalysts used in PDO synthesis are highly sensitive to impurities like H₂S or excess CO₂.

- Accurate gas composition analysis prevents catalyst poisoning, extends catalyst lifespan, and reduces regeneration frequency.

- Reactor Control and Conversion Efficiency

- Real-time monitoring of CO and H₂ concentrations supports precise stoichiometric control.

- Stable gas inputs ensure optimal reactor temperature and pressure settings, maximizing conversion rates and product purity.

- Safety and Environmental Assurance

- Overconcentration of flammable gases like H₂ presents explosion risks.

- Integrated gas analyzers act as safety monitors by triggering alarms and control systems when thresholds are exceeded.

- Quality Assurance of PTT Polymer

- Variations in syngas quality directly impact the PDO monomer structure, which in turn affects polymer crystallinity and mechanical properties.

- Monitoring ensures consistent polymer output that meets strict industry standards for tensile strength, dyeability, and thermal stability.

Case Example: A 15% Reduction in Off-Spec Material

A Southeast Asian fiber manufacturer integrated inline syngas analyzers into their PDO production line. Within three months, they reported:

- A 15% drop in off-spec PTT batches

- A 12% improvement in PDO conversion efficiency

- Enhanced ability to fine-tune reactor conditions during peak load periods

This not only saved operational costs but significantly improved plant uptime and product quality.

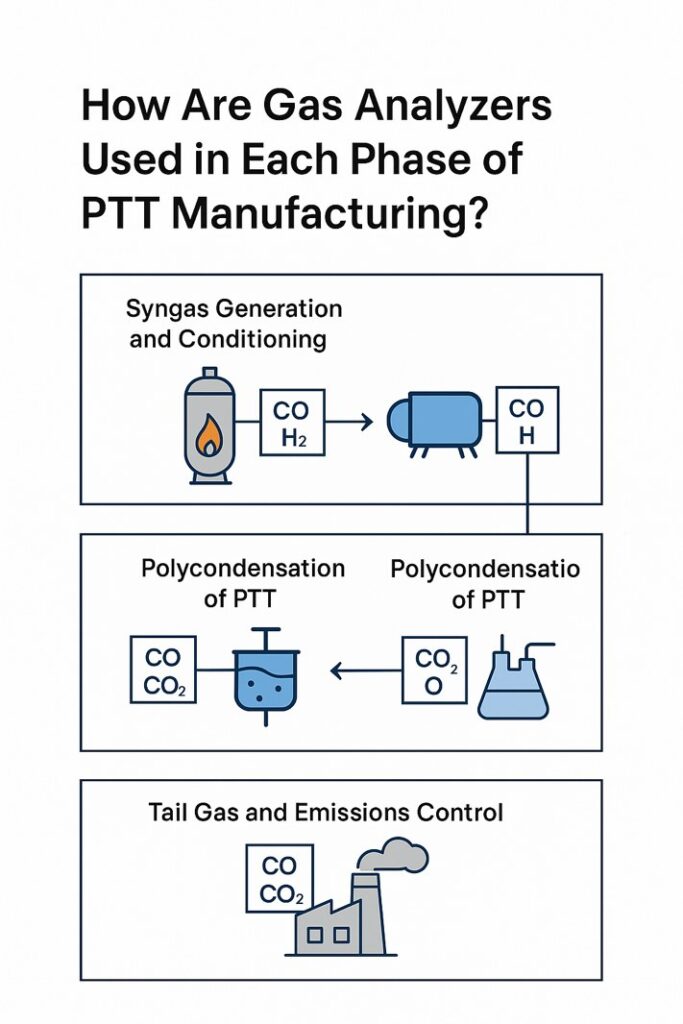

How Are Syngas Analyzers Used in Each Phase of PTT Manufacturing?

From Feedstock to Final Product—A System-Wide Monitoring Strategy

The production of polytrimethylene terephthalate (PTT) involves a series of interconnected chemical processes, each of which is sensitive to gas-phase dynamics. Integrating syngas gas analyzers into each critical stage provides a holistic solution to ensure product quality, reduce energy waste, and maximize operational efficiency.

Let’s break down the specific roles of gas analyzers at each step of the PTT production line:

1. Syngas Generation and Conditioning

Purpose of Monitoring: Ensure feedstock purity and correct CO/H₂ ratios

- Gas analyzers are installed immediately after syngas generation units (typically from steam reforming or biomass gasification) to monitor the molar balance between CO and H₂.

- Real-time adjustments are made via control valves or gas blending systems based on analyzer output.

- Removal of impurities such as H₂S, NH₃, or moisture is verified by measuring post-treatment gas purity.

Impact: Guarantees a stable and clean feed entering the downstream PDO synthesis reactor, minimizing reprocessing or shutdowns.

2. 1,3-Propanediol (PDO) Synthesis

Purpose of Monitoring: Maximize conversion efficiency and protect catalysts

- In this critical phase, gas analyzers monitor the inlet and outlet streams of the reactor to measure real-time consumption rates of CO and H₂.

- Changes in gas flow or reaction temperature can be corrected automatically through feedback loops informed by analyzer data.

- Catalyst performance is tracked via CO₂ and CH₄ by-product levels.

Impact: Enhances yield of PDO and extends catalyst lifetime by preventing overexposure to unbalanced syngas compositions.

3. Polycondensation of PTT

Purpose of Monitoring: Optimize polymerization conditions

- Although this step primarily involves liquid-phase chemistry, off-gas analysis plays a critical role.

- Gas analyzers monitor the evolution of CO₂ and VOCs (volatile organic compounds) from the polycondensation reactor.

- This data is used to fine-tune pressure, temperature, and residence time, ensuring consistent polymer chain growth.

Impact: Helps achieve consistent molecular weight, reduces discoloration, and improves mechanical properties of the PTT fibers.

4. Tail Gas and Emissions Control

Purpose of Monitoring: Ensure environmental compliance and energy recovery

- Tail gas streams, often containing unreacted syngas components or by-products, are monitored continuously.

- Analyzers detect CO, CO₂, CH₄, and H₂ concentrations before venting or routing gases to recovery systems (e.g., burners or pressure swing adsorption).

- Real-time data supports automatic flaring control or enables routing of combustible gases for secondary energy use.

Impact: Reduces carbon emissions, minimizes safety hazards, and contributes to plant-wide energy efficiency goals.

Summary Table: Analyzer Functions by Phase

| Production Phase | Analyzer Functions | Primary Benefits |

| Syngas Generation | CO/H₂ ratio, impurity detection (H₂S, NH₃) | Feedstock quality assurance |

| PDO Synthesis | Consumption rate tracking, by-product detection | Maximize yield, catalyst protection |

| PTT Polycondensation | Off-gas CO₂/VOC analysis | Polymer quality control |

| Tail Gas Handling | Emissions profiling, combustible recovery | Compliance and energy recovery |

By strategically placing gas analyzers throughout the production system, manufacturers create a closed-loop, data-driven environment. This not only strengthens product consistency but also aligns with broader goals of process optimization, real-time monitoring, and emission control.

What Factors Should Be Considered When Choosing a Syngas Analyzer for PTT?

A Misfit Instrument Can Undermine an Entire Operation

Selecting the right gas analyzer is more than choosing a model—it’s aligning it with process dynamics.

| Parameter | Importance in PTT Production | Recommended Range |

| Response Time | Critical for real-time adjustments | < 1 second |

| Detection Limit | Needed for trace analysis of CO, H₂, CO₂ | ppm-level |

| Integration Capability | Must interface with DCS/SCADA systems | Ethernet/Modbus |

| Durability | Withstand high-temp, corrosive gases | Stainless steel housing |

Investing in a compatible system improves operational efficiency and reduces downtime risk.

How Does Syngas Analyzers Support Energy Savings and Regulatory Compliance?

Sustainability Is Not Optional—It’s Measurable

Modern chemical manufacturing faces increasing pressure to reduce carbon emissions and meet energy benchmarks. Gas analyzers support these goals by enabling:

- Emission control through real-time feedback on CO₂ and unreacted gases.

- Energy efficiency by identifying underperforming process zones.

- Compliance with regional standards like EPA and REACH by validating gas discharge levels.

By embedding gas composition analysis into daily operations, manufacturers can optimize fuel use and minimize environmental impact.

Conclusion: Driving PTT Production Toward a Smarter Future

Syngas gas analyzers play a central role in modern PTT production. They not only monitor key gases like CO and H₂ but also empower operators to make fast, data-driven decisions. From increasing yield and improving product consistency to enhancing energy use and regulatory compliance, these devices are more than analytical tools—they are strategic assets. Embracing such technologies is no longer optional for competitive manufacturers—it’s essential for those aiming to lead in quality, efficiency, and sustainability.