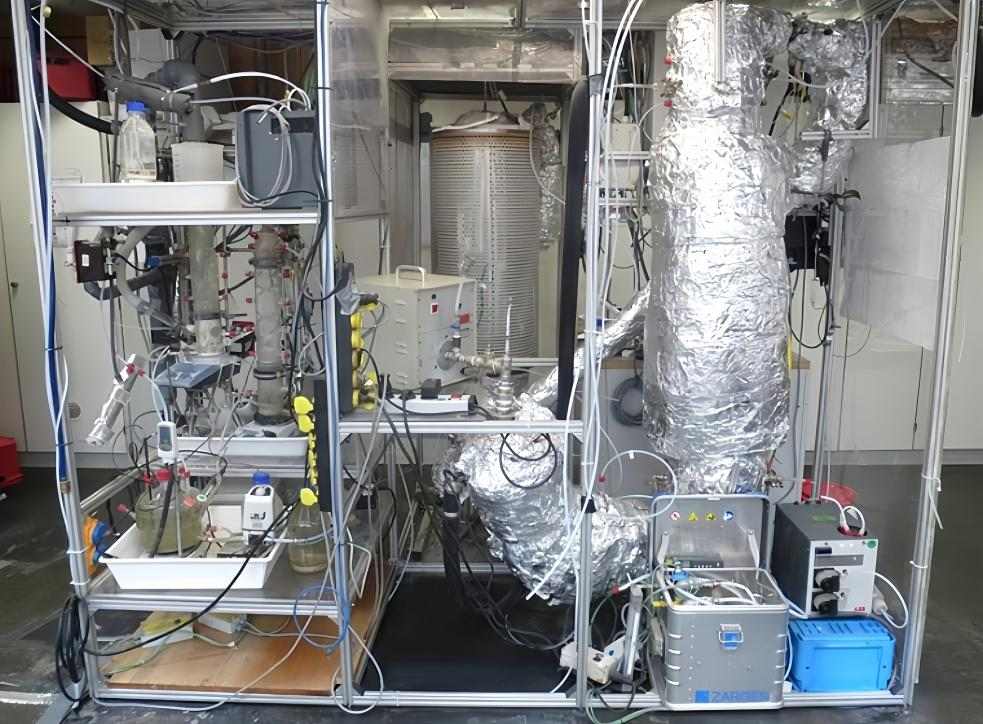

Furnace emissions face growing regulatory scrutiny worldwide. Authorities demand proof of compliance not only from industrial stacks but also from laboratory-scale test systems. Laboratories carry a dual role: verifying emission levels for regulatory reporting and driving R&D on cleaner combustion. This means labs must deal with complex gas mixtures that contain both major combustion products and trace acid gases.

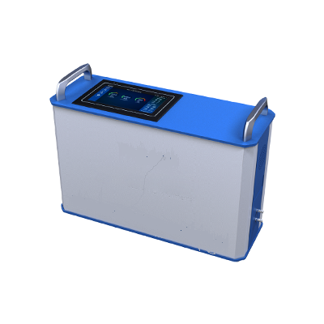

A portable FTIR gas analyzer offers a practical solution. It can measure a wide range of gases—NOx, SOx, CO, CO₂, H₂O, HCl, HF, and NH₃—within one instrument. Although P₂O₅ remains outside its scope, this model can still cover the key gases most labs must monitor. With heated sampling and moisture tolerance up to 20%, it is well suited for furnace exhaust streams where humidity and dust complicate measurement.

Below I synthesize why a portable FTIR is the appropriate gas analyzer choice and then unpack the practical engineering, QA, and procurement decisions you must make to convert instrument capability into trustworthy lab data.

Why Is a Portable FTIR Gas Analyzer the Smarter Choice for Furnace Emissions Testing?

(Portable FTIR Gas Analyzer ESE-FTIR-100P)

One of the strongest advantages of a portable FTIR gas analyzer lies in its spectral simultaneity. By capturing the full mid-infrared spectrum, the analyzer quantifies many gases at once. In a single measurement it can separate NOx, SOx, CO, CO₂, H₂O, HCl, HF, and NH₃ with high specificity. This approach eliminates the need for multiple single-gas analyzers and avoids complex sampling splits that often introduce error. For laboratories managing diverse test programs, that efficiency is not only convenient but also essential for producing data sets that are internally consistent.

Equally important is its ability to deliver laboratory-grade fidelity in a portable frame. These instruments combine bench-style optics with field-ready features: heated cells and lines to manage high-moisture gas, an internal pump to simplify setup, and rugged spectrometers designed to handle demanding exhaust conditions. The result is an analyzer that can move from a bench test to a near-stack sampling point without major infrastructure or civil works. For R&D teams, this flexibility means faster iteration, less downtime, and data that reflects actual furnace conditions.

There is also a clear cost–time advantage compared to fixed continuous emission monitoring systems (FTIR-CEMS) or gas chromatographs (GCs). Portable FTIR gas analyzers deliver quicker results with lower capital investment, making them ideal for periodic lab campaigns, pilot projects, or feasibility studies. While they cannot fully replace fixed CEMS for 24/7 regulatory reporting, they bridge the gap between occasional research and compliance testing. For many laboratories, this balance of precision, portability, and affordability defines the value proposition.

With the advantages established, the remaining question is operational — how to manage the sampling and QA challenges that determine whether the FTIR’s theoretical advantages become real-world accuracy.

What Operational Challenges Do Laboratories Face When Using a Portable FTIR Gas Analyzer?

Furnace exhaust is not a simple stream. It carries high water vapor, fine dust, and reactive gases. At up to 20% water content, condensation becomes the biggest risk. When vapor condenses, acids like HCl and SO₂ adsorb onto wet surfaces, shifting the spectral baseline and underestimating true values. Dust adds another layer of complexity. Particulates scatter the infrared beam and contaminate the optical path, slowly reducing sensitivity. In short, without careful sampling design, the accuracy of the analyzer is compromised before the spectra even reach the software.

Designing a sampling system that works

The foundation of reliable data lies in a heated sampling train. A heated probe paired with a transfer line set between 180–200 °C prevents condensation and acid loss. The next step is filtration. A two-stage approach works best: a coarse upstream filter to block large ash, followed by a replaceable P2 cartridge for finer dust. In “minimal dust” conditions, the P2 filter alone may be enough, but in clinker-rich or high-ash scenarios both stages are non-negotiable.

Pump choice also matters. An internal pump boosts portability and keeps the unit self-contained. External pump boxes, however, provide steadier flow and are easier to service in long campaigns. Engineers often weigh weight and convenience against stability and maintenance access. A clear schematic with probe, heated line, filter, pump, and analyzer cell helps standardize setup across operators.

Sampling System Checklist for Portable FTIR Gas Analyzer

| Component | Action | Rationale |

| Heated probe | Maintain ≥180 °C | Prevent condensation and acid loss |

| Heated transfer line | Keep 180–200 °C along full length | Avoid cold spots and adsorption |

| Prefiltration | Install coarse filter upstream | Block larger ash particles |

| Fine filtration | Use replaceable P2 cartridge | Protect optics from fine dust |

| Pump selection | Internal for portability; external for long campaigns | Balance mobility vs. stability |

| Leak check | Verify all joints under vacuum | Ensure sample integrity |

| Schematic | Standardize probe → line → filter → pump → analyzer | Improve operator consistency |

This checklist turns setup from a trial-and-error task into a repeatable engineering practice. With it, labs can cut down on drift, minimize downtime, and ensure each campaign produces defensible data.

Configuring the analyzer and defining measurement ranges

Setting the right measurement ranges is more than paperwork — it defines whether your spectra will produce usable results. Each species in furnace exhaust has its own dynamic behavior. Some, like CO₂ and H₂O, appear at high background levels, while others, like HF or HCl, occur in trace ranges but carry outsized compliance weight. A balanced configuration ensures the analyzer can capture both without saturating or drifting.

Span check gases should match the expected ranges, not just vendor defaults. This practice keeps calibration relevant to the furnace chemistry you actually test. The table below outlines typical lab ranges and recommended span gases for core species.

Practical Measurement Ranges for Portable FTIR Gas Analyzer:

| Species | Typical Lab Range | Recommended Span Check Gas | Notes on Detection |

| NOx | 10–300 ppm | NO at 100 ppm | Distinguish NO vs. NO₂; overlap possible |

| SOx | 10–200 ppm | SO₂ at 100 ppm | Watch for SO₂/SO₃ spectral overlap |

| CO | 0–10 ppm | CO at 5 ppm | Sensitive to baseline drift |

| CO₂ | 3–10 % | CO₂ at 5 % | High background; avoid saturation |

| H₂O | 2–20 % | N/A (moisture balance) | Drives baseline stability |

| HCl | 0–5 ppm | HCl at 2 ppm | Adsorption on cold surfaces |

| HF | 0–5 ppm | HF at 2 ppm | Cross-interference with HCl |

| NH₃ | ≥2 ppm (detection limit) | NH₃ at 10 ppm | Reactive; prone to loss in wet lines |

| P₂O₅ | Not supported | N/A | Strong absorption; outside FTIR library |

In practice, engineers should monitor dynamic range and cross-sensitivity. For example, NO and NO₂ share bands that demand careful fitting, while HCl and HF overlap enough to require high-quality libraries. Without these precautions, numbers may look precise but fail under audit.

Software and spectral libraries — hidden enablers

Even the best optics fail without robust software. Vendors provide a pre-configured analyte list that covers common combustion gases. This works for most labs, but not all. When unknown peaks appear, analysts must collect high signal-to-noise spectra and apply chemometric deconvolution. Expanding the library with certified reference spectra is the only way to secure accurate results. This means laboratories should budget for periodic library updates and expert fitting support, especially if research involves novel fuels or additives.

Conclusion

Furnace emissions testing in the laboratory is no longer a narrow compliance task. It is now a balancing act between regulatory precision, engineering practicality, and research agility.

Yet the story does not end with hardware. Sampling controls, analyzer configuration, and software libraries set the stage, but data quality depends on disciplined follow-through. Without structured QA/QC, calibration routines, and careful workflow design, even the most advanced FTIR can produce misleading results.

That is why this article is only the first step. Let’s move to Part II of this series — How to Ensure Data Integrity in Furnace Emissions Testing with Portable FTIR gas analyzer?

FAQ — Portable FTIR Gas Analyzer for Furnace Emissions in Laboratory

Q1: What gases can a portable FTIR gas analyzer measure in furnace exhaust?

A1: A capable portable FTIR gas analyzer can quantify multiple species simultaneously, such as NOx, SOx, CO, CO₂, H₂O, HCl, HF, and NH₃. (Note: ESEGAS models do not support P₂O₅.) By measuring all from one optical path, it avoids sampling splits and ensures internal consistency.

Q2: How does the moisture content in exhaust affect FTIR measurements?

A2: High moisture (up to ~20%) poses risks: condensation can shift baselines or cause acid adsorption, and water vapor produces strong absorption bands. To mitigate this, the sampling system must be fully heated (probe + transfer line) and designed to avoid cold spots.

Q3: How often should calibration be done for a portable FTIR system?

A3: Full zero/span verification is recommended every six months. Between these, daily or weekly quick checks (or electronic zero) help track drift. The lab is responsible for supplying calibration gases for ongoing verification, while the vendor typically performs factory calibration prior to shipment.

Q4: How do you know the measurement is reliable (traceability)?

A4: Labs build an uncertainty budget covering spectral fitting error, sampling bias, temperature stability, and calibration gas uncertainty. Documenting each contribution in a checklist provides traceability and supports data defensibility under audit.

Q5: Should I choose a portable FTIR or fixed CEMS/GC for furnace emissions?

A5: It depends. Use portable FTIR gas analyzer if your test campaigns are intermittent, you need mobility, and your species list is broad. Choose fixed CEMS or GC when continuous real-time regulatory compliance is needed. A use-case checklist (test frequency, regulatory needs, dust/moisture load) helps guide the decision.

Q6: What training do operators need to run a portable FTIR system reliably?

A9: Even though many systems are user-friendly, labs should organize a short formal training module, designate a “power user,” and require at least video + two live remote sessions from the vendor. This builds resilience for calibration, troubleshooting, and data QA.