1. Purpose of testing

Testing of S02 component loss for CEC201 Gas Cooler in normal temperature state.

The problem of SO2 component loss can be effectively reduced, because CEC201 is allocated new anti-polymer heat-exchanger glass tube ECB0009 and ECB0010.

2.Test experimental conditions

3.Test specific plan

3.1. Calibration

Zero calibration: SO2 meter shows 0.3 mg/m3.

Full scale calibration:SO2 meter shows 280.5 mg/m3(standard gas concentration 280 mg/m3)

SO2 concentration in mix gas :50 mg/m3 and 200mg/m3

4.Product photos

The right heat-exchanger tube is normal tube.

The left is new anti-polymerized water type tube ECB0010 and it’s different from the on the right. There is no water drop on the glass wall.

5. Experimental records

Test conditions:

Environmental temperature : 28℃, Environmental humidity: 80% RH

Test Cabinet temperature: 30℃

Sample gas flow: 2 L/min

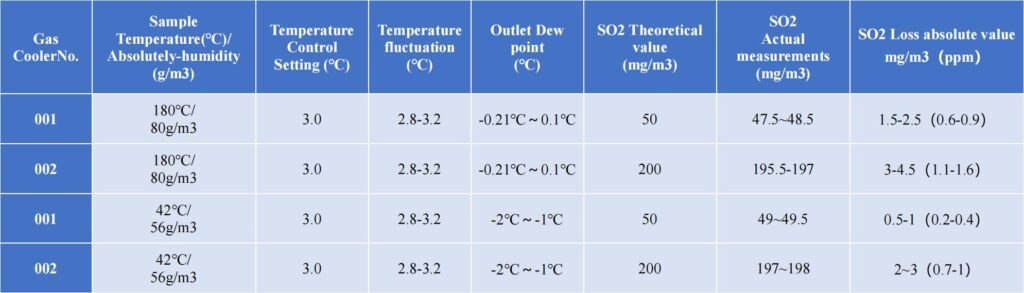

No. 001 and No. 002 Coolers are tested with anti-polymerized water type heat-exchanger glass tube (ECB0009&ECB0010) under two concentrations conditions of standard gas.

6. Conclusions

The SO2 loss rate experiment was carried out, when the temperature of sample gas is 42℃and the concentration of SO2 is 200mg/m3(70 ppm), using the Cooler equipped with anti-polymerization water heat-exchanger glass pipe.

The absolute SO2 loss value was 2-3 mg/m3 then the loss rate was between 1-1.5%.

So the requirement of loss rate not more than 2% can be basically met.