ESEGAS recently deployed the ESE–LASER–200WM HCl gas analysis system (0–50 ppm) at a waste-to-energy incineration plant overseas. This advanced system uses Tunable Diode Laser Absorption Spectroscopy (TDLAS), delivering real-time HCl measurements in demanding flue-gas environments.

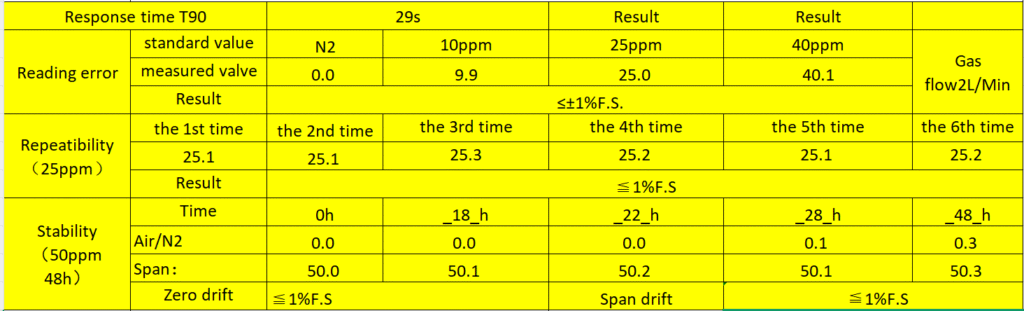

Thanks to our rigorous in-house validation, the system consistently achieved ±1% full-scale accuracy, repeatability, and drift—giving plant engineers reliable data they can trust. This level of precision not only tightens emission control but also strengthens compliance with evolving environmental regulations.

How Does the HCl Gas Analysis System Leverage TDLAS for Enhanced Measurement Reliability?

Tunable Diode Laser Absorption Spectroscopy (TDLAS) excels in delivering high selectivity, sensitivity, and fast response—perfect for real-time HCl monitoring. First, it tunes to HCl’s specific absorption line, avoiding interference from other gases even in complex flue environments. This spectral precision ensures readings reflect true HCl concentration, not cross-gas noise.

Additionally, TDLAS employs a non-intrusive laser beam rather than exposed sensors. As a result, it avoids direct contact with corrosive or particulate-laden flue gas, reducing maintenance and long-term drift. That means operators spend less time cleaning or calibrating and more time trusting the data.

Furthermore, TDLAS delivers results in seconds. This rapid response allows plant teams to react immediately to HCl spikes, safeguarding equipment and ensuring regulatory compliance. In contrast, slower sampling technologies may miss transient emission peaks and delay corrective action.

In summary, TDLAS brings together:

- High specificity: Targets HCl lines for accurate measurements

- Non-intrusive design: Minimizes wear and maintenance

- Fast response: Enables proactive control and compliance

Thus, the ESE-LASER-200WM’s TDLAS core offers stability, precision, and reliability under harsh conditions—giving plant operators clear, trustworthy data for confident emission management.

Why Did Rigorous In-House Testing Matter for the HCl Gas Analysis System’s Deployment?

Before shipment, we pushed the ESE-LASER-200WM through exhaustive in-house trials at ESEGAS. We focused on three key performance metrics—accuracy, repeatability, and drift—and held all within a tight ±1% full-scale band.

By doing so, we ensured the analyzer would arrive pre-qualified for field use. Consequently, our customer could begin operations with minimal calibration needed on site. Even better, this approach:

- Reduces installation delays, since no extensive tuning is required

- Boosts operator confidence, thanks to consistent data from day one

- Cuts maintenance costs, by relying on factory-grade stability

Moreover, in-house validation reflects our commitment to quality control. It mimics real-world conditions and catches issues early—long before the unit reaches a flue-gas stack. Ultimately, this step not only safeguards performance—it reinforces trust and reliability at every turn.

How Will This HCl Gas Analysis System Enhance Environmental Compliance?

By deploying the HCl gas analysis system, the client unlocks powerful emission control benefits:

- Continuous real-time monitoring reveals HCl fluctuations instantly.

- Rapid response handles HCl spikes before they escalate.

- Secure data logging aligns with UL standards and environmental regulations.

These capabilities empower plant managers to track trends, act swiftly, and confidently report compliance. With round-the-clock data, teams can spot deviations early, implement corrective measures, and maintain clean operations. As a result, they can prove regulatory adherence and reduce the risk of violations.

Furthermore, real-time tracking makes environmental responsibility more than a checkbox—it becomes an ongoing practice. Teams can analyze historical data to optimize scrubber performance and minimize corrosion risks. In this way, the system not only ensures compliance—it drives continuous improvement. By marrying precision measurement with actionable insight, our HCl gas analysis system transforms emission management from reactive to proactive.

Conclusion

The ESE–LASER–200WM HCl gas analysis system showcases how advanced measurement technology adapts to real-world industrial needs. Its precision, resilience, and compliance-readiness create value for operators and regulators alike. If you’re managing emissions in power, waste, or chemical facilities, let’s collaborate. Connect with us to explore how TDLAS–based gas analysis can elevate your monitoring strategy.