Recently, an iron and steel plant has successfully completed the installation and commissioning of a continuous emission monitoring system (CEMS) for flue gas with the help of ESEGAS’s technical team. This marks a solid step forward in environmental protection and pollution control. The installation of the CEMS will effectively help the plant monitor the concentration of pollutants in the flue gas in real time. This ensures that the emissions meet the national environmental standards.

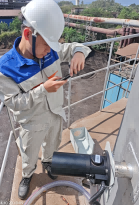

CEMS (Continuous Emission Monitoring System) is a system for continuous monitoring of emission substances. It is capable of real-time monitoring and recording of key pollutants such as sulphur dioxide, nitrogen oxides and particulate matter in the flue gas. The installation and commissioning took several weeks. The project team overcame the difficulties of complex piping arrangement, equipment debugging and high temperature environment. They finally completed the debugging and testing of all system functions as scheduled. This ensured the stable operation of the equipment and the accuracy and reliability of the data.

The person in charge of the steel plant said that the installation of the CEMS reflects the plant’s strict adherence to environmental regulations. It is also an important measure for the enterprise to practice green production and fulfil its social responsibility. In the future, the plant will further reduce pollutant emissions by strengthening data analysis and control. They strive to contribute to local ecological and environmental protection.

It is understood that the CEMS system installed this time has been strictly calibrated and certified. All the data can be networked with the environmental protection department to achieve information sharing and real-time supervision. This initiative enables the environmental protection department to regulate plant emissions in a more timely and effective manner. It promotes green upgrading and sustainable development across the industry.

The installation and commissioning of the CEMS system marks a significant improvement in the intelligence and scientific level of the steel plant’s environmental management. It lays a solid foundation for the long-term stable development of the enterprise.

If you would like to know more, please get in touch with us!