In waste incineration, trace gases like ammonia (NH₃) and hydrogen fluoride (HF) pose serious environmental and regulatory risks. Many jurisdictions now cap NH₃ emissions at a few mg/Nm³ and HF even lower. To stay compliant, plants must reliably detect these gases—even at ultra-low levels. Traditional methods—manual sampling, periodic lab assays, or sensor probes—struggle with delays, calibration drift, and heavy maintenance. In contrast, a wall-mounted TDL gas analysis system operates in situ, delivers real-time data, and maintains stability over time. This technology promises a radical shift: monitor NH₃ (and optionally HF) continuously without cumbersome sampling chains.

This article focuses on the role, design principles, and practical impact of wall-mounted TDL gas analysis system in incinerator settings (flue gas up to ~150 °C). It does not delve deeply into unrelated gas species, or exhaustively catalog all vendors. The target readers range from technically curious professionals to plant engineers seeking actionable insight. Whether you already know a bit about gas analysis or lead instrumentation in a plant, you’ll find both conceptual clarity and practical guidance here.

What Core Principles Govern a TDL System for NH₃ & HF?

(ESEGAS Wall-Mounted Online TDL Gas Analysis System)

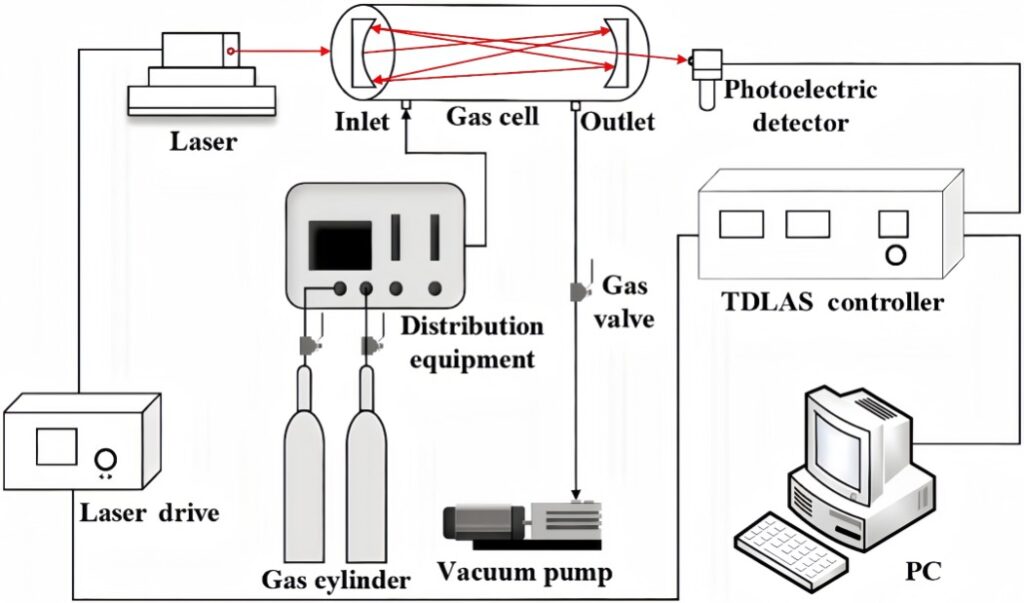

Spectroscopic techniques—especially Tunable Diode Laser Absorption Spectroscopy (TDLAS)—offer strong advantages for trace NH₃ / HF monitoring. By tuning a diode laser to the gas’s absorption wavelength and measuring attenuation, TDLAS relates intensity drop to concentration via Beer–Lambert’s law.

TDLAS suits trace measurement because it delivers:

- High selectivity: it targets narrow absorption lines specific to NH₃ or HF, reducing interference

- Fast response: measurement in seconds or sub-seconds

- Low drift & stability: minimal baseline shift over time

However, real flue gases pose challenges:

- Interference & cross-sensitivity: overlapping absorption from water vapor, CO₂, or other gases

- Temperature & pressure shifts: absorption line shapes shift with thermal and pressure variations

- Humidity / moisture effects: water vapor lines dominate the IR spectrum and can mask weak NH₃/HF signals

Designers must choose absorption lines that minimize overlap and apply signal processing (e.g. harmonic detection) and calibration techniques to suppress interference.

How Do You Design a Robust TDL System for Incinerator NH₃ & HF?

a. Sampling/probe + preconditioning unit

To succeed in real-world incinerator settings, a good TDL system merges sampling, preconditioning, and analysis into a compact, wall-mounted unit. A compact sampling/probe + preconditioning unit should combine:

- A heated probe or isothermal path to keep gas above dew point

- A fine dust filter / particulate trap (e.g. sintered stainless steel)

- Backflush or purge line to clear particles and deposits

- Temperature stabilization elements (heaters, insulation)

This arrangement ensures the laser cell sees only gas with minimal particulates.

b. Analysis Module

The heart is the optical cell: a multipass cell or folded path to boost sensitivity. Use a tunable diode laser source tuned to NH₃ or HF absorption lines. A photodetector or photodiode reads transmitted light. The electronics perform modulation (e.g. wavelength modulation) and lock-in detection to improve signal-to-noise.

c. Communication & Integration

Output should support common industrial links: 4–20 mA analog output, RS-485 (Modbus), and alarm contacts. Make SCADA integration straightforward. Provide diagnostic data (error flags, optical signal strength, health status) to driving automation systems.

What Insights Do Case Scenarios Offer for a TDL System in Real Life?

When NH₃ sits below 0.3 mg/Nm³ and HF under 0.2 mg/Nm³, measurement challenges multiply. The signal from the laser path becomes extremely weak, and any baseline drift or optical noise easily swamps the signal. At these levels, detection limits, signal-to-noise ratio (SNR), and stability over time become the battleground.

- Detection limits must lie significantly below 0.1 mg/Nm³ to reliably resolve the signal above noise floors.

- SNR becomes critical: you may need longer optical paths or signal averaging to boost SNR, though that risks slower response.

- Stability is key: baseline drift, optical contamination, or temperature fluctuations can mislead readings over hours or days.

In short, the TDL system must squeeze out meaningful trace data from a noisy, borderline regime while maintaining confidence in each reading.

Once the incinerator introduces a DeNOₓ system, ammonia slip may push NH₃ levels toward 5 mg/Nm³, and HF could reach ~2 mg/Nm³. The analyzer must gracefully scale from trace to moderate levels without losing linearity or precision.

- Scalability: the system should support auto-ranging or dual-scale operation to shift measurement span dynamically.

- Range switching: smooth transitions between low and high ranges, without causing measurement “dead zones.”

- Linearity: maintain proportional response across both ends of the spectrum (from ~0.1 to 5 mg/Nm³).

A robust design anticipates this shift in operating regime, so the analyzer does not become obsolete or inaccurate at higher gas loads.

TDL Online vs. Conventional Methods: A Comparative View on Gas Analysis:

| Feature | TDL Online (Wall-Mounted) | Conventional Methods (wet chemistry, sensors, sampling |

| Maintenance burden | Low: no reagents, minimal moving parts | High: reagents, pumps, filters, regular calibration |

| Response time / dynamics | Seconds or less, real time | Minutes to hours, often delayed |

| Accuracy & drift | High specificity, low drift over time | Prone to drift, cross interference, human error |

| Total cost & downtime | Lower lifecycle cost, fewer shut-downs | Higher operating cost, more downtime |

| Reliability | Continuous, self-diagnosing, redundant modes possible | Susceptible to sampling line failure, clogging, delays |

From this comparison, a TDL system stands out because it blends fast reaction, low upkeep, and continuity. Over the plant lifetime, they often deliver better cost of ownership—less downtime, fewer consumables, and more consistent data quality.

What Model Fits Best and How Do You Evaluate Its Economics in a TDL System?

1. Suggested System: ESE-LASER-200WM (Or Equivalent Wall-Mounted Laser Unit)

a. Why It Fits Well

The TDL gas analysis system is built for industrial gas environments. Its design supports heated paths and sample extraction beyond 600 °C, enabling it to handle hot flue gases (up to ~150 °C) with headroom for harsher conditions. Modularity allows swapping in or out components (sampling, preprocessing, control) to adapt to site needs.

b. Limitations & Practical Caveats

Because your NH₃ / HF levels at low concentration are extremely small, a single analyzer may struggle to detect both gases in the same optical path. You might need separate analyzers tailored to each gas (NH₃ and HF) with optimized optical paths and calibration ranges. Also, some modules offered by this family focus more on NH₃ (or HCl / HF) as primary gas; check if a dual-gas configuration is feasible for your specific low-level ranges.

2. Cost & ROI Discussion

a. Capital Costs

Your upfront cost includes analyzer units, installation labor, heated lines, wiring, mounting hardware, and SCADA interface work. For a wall-mounted TDL unit with heated path and sampling module, you might expect a cost in the range of tens of thousands of USD (or equivalent local currency), depending heavily on customization, site conditions, and wiring complexity.

b. Operating Costs

Running costs include periodic calibration gases, preventive maintenance (filters, purge gas), spare parts (windows, laser modules), and occasional service visits. Because TDL systems avoid consumables like reagents, their operating burden tends to stay moderate.

c. Value & Return on Investment

- Regulatory compliance: avoiding fines or shutdowns pay off quickly.

- Emissions avoidance: tighter NH₃ control reduces slip and penalties.

- Process tuning: real-time data allows optimizing catalyst and reagent use, saving costs.

- Reduced downtime: fewer manual sampling or system failures save labor and loss time.

Over the system’s lifetime, ROI often comes from operational efficiency and compliance benefits rather than simply equipment cost.

3. Integration & Reporting

a. SCADA & Remote Monitoring

The TDL system supports 4–20 mA analog output and RS-485 (Modbus) for easy SCADA integration. You can pull live NH₃ / HF data, status flags, and alarms into your control center. This ensures rapid alerts and remote health checks without local intervention.

b. Trend Analysis & Predictive Maintenance

Beyond raw concentration data, you can record trend curves, detect drift, and trigger maintenance before failures. Over time, you’ll build a historical database for:

- Baseline drift tracking

- Calibration schedule optimization

- Anomaly detection (optical contamination, component aging)

This data-driven approach transforms the analyzer from merely a sensor into a management tool.

Conclusion

Wall-mounted online TDL system for gas analysis addresses a real gap in incinerator emissions monitoring. They let you measure NH₃ (and HF, when configured) continuously, directly in the flue line (up to ~150 °C). Because of high specificity, low drift, and minimal sampling lines, they support both regulatory compliance and smarter process control. In short, they bridge operational reliability with emission control needs.

This piece is not just a product pitch — it’s an invitation to collective improvement. If you’re an engineer, operator, or regulator dealing with NH₃ / HF measurement headaches in incineration, I’d love to hear your story. Let’s exchange insights, troubleshoot challenges, and build toward safer, smarter incinerators together.

FAQ: Wall-Mounted Online TDL Gas Analysis System for NH₃ & HF in Incinerators

Q1: What is a TDL gas analysis system and how does it work for NH₃ / HF measurement?

A: A TDL (Tunable Diode Laser) gas analysis system uses a diode laser tuned to specific absorption wavelengths of a target gas. The system measures how much laser light is absorbed over a known path, and computes gas concentration via the Beer–Lambert relation. Because it targets narrow spectral lines, it offers high selectivity and speed. This makes TDL well suited for trace NH₃ and (optionally) HF monitoring in flue gas streams.

Q2: Why is a wall-mounted configuration advantageous in incinerator settings?

A: A wall-mounted design places the system directly on or near the stack wall. This reduces sample transport distance, lowers delay and distortion, and minimizes tubing complications. It also saves space, simplifies installation, and reduces maintenance burden compared with remote sample systems.

Q3: Can a TDL system detect ultra-low NH₃ concentrations (<0.3 mg/Nm³)?

A: Yes — properly designed TDL systems can achieve very low detection limits (ppm or sub-ppm levels, depending on path length, signal processing, and noise suppression). For NH₃ in exhaust systems, research has achieved limits in the tens of ppm (or normalized path-sensitivity) using careful line choice and interference suppression. However, pushing into the ultra-low mg/Nm³ regime requires optimal optical path, stable baseline, and compensation for interfering species.

Q4: What are the main interferences or challenges when measuring NH₃/HF in flue gas?

A: Key challenges include:

- Cross-absorption / spectral overlap from water vapor, CO₂, or other combustion gases

- Temperature, pressure, and gas composition shifts causing line broadening or shift

- Baseline drift over time

- Optical fouling or contamination from dust, particulates, or aerosols

- Condensation or corrosion of sample lines if gas cools

Overcoming these requires smart line selection, optical design, calibration routines, and gas conditioning.

Q5: Will the wall-mounted TDL system handle flue gas at 150 °C and dust loading?

A: Yes — with proper design. The system must use heated or isothermal sample paths, corrosion-resistant materials, and dust filters or purge/backflush systems. The TDL system should prevent cooling or condensation inside optical paths. Many commercial laser analyzers are rated to handle high temperature environments (even much higher than 150 °C) with proper design.

Q6: How do you calibrate a TDL system and maintain accuracy over time?

A: A reliable calibration strategy includes:

- Periodic auto-zero/auto-span routines

- Use of internal reference cells or built-in calibration gas

- Validation checks with external standards

- Drift monitoring and trend alarms

- Firmware that triggers calibration before measurement error grows

This ensures stability of TDL system across low and higher concentrations (e.g. up to 5 mg/Nm³ NH₃).