Gas leaks and hazardous concentrations can jeopardize industrial safety. Traditional detectors are bulky and slow. Handheld gas analyzers offer a compact, fast, and accurate solution for real-time gas monitoring.

Handheld gas analyzers provide real-time monitoring of gases like CH₄, CO₂, H₂S, and O₂ in industrial environments. Their compact design, NDIR, and electrochemical sensors ensure high accuracy, fast response, and wide applicability across sectors such as waste treatment, landfills, and biogas production.

While the core value lies in real-time detection, the broader impact of these devices goes far beyond simple measurement, transforming safety, compliance, and process optimization in industrial operations.

Why Are Handheld Gas Analyzers Essential In Landfill Gas Monitoring?

Uncontrolled landfill gas emissions can trigger explosions, environmental fines, and severe health threats. Methane (CH₄) and carbon dioxide (CO₂), the dominant components of landfill gas, are both flammable and potent greenhouse gases. Without precise and regular monitoring, these emissions can accumulate to dangerous levels, jeopardizing site personnel and nearby communities.

Handheld gas analyzers offer a practical, accurate, and immediate solution. Devices like the IR-GAS-400H utilize NDIR technology to detect CH₄ and CO₂ in real-time, with a high accuracy of ±2%FS and resolution down to 0.01%. Their portability allows technicians to perform spot checks across large, uneven landfill surfaces where fixed systems are impractical or too costly to install.

Moreover, their fast response time (T90 < 15s) ensures that operators can quickly identify gas pockets or leaks, enabling preventive actions before concentrations become hazardous. The IR-GAS-400H is especially useful during landfill cap inspections, perimeter assessments, and leachate well maintenance, where access is limited and rapid feedback is crucial.

By enabling mobile, multi-point gas surveillance, handheld analyzers play a critical role in maintaining regulatory compliance, optimizing gas recovery, and protecting both environmental and human health. Their deployment not only reduces the risk of explosive events but also supports carbon credit initiatives by providing trustworthy emissions data.

How Do Biogas Facilities Benefit From Portable Gas Analyzers?

Inconsistent gas composition can compromise energy yield and violate environmental standards. In biogas plants, the quality of the gas—primarily methane (CH₄), carbon dioxide (CO₂), and hydrogen sulfide (H₂S)—varies depending on feedstock, temperature, and microbial activity. Without accurate and frequent monitoring, operators may face combustion inefficiencies, equipment corrosion, and regulatory penalties.

Portable gas analyzers enable on-the-spot, multi-gas monitoring across the entire production chain. Devices like the IR-GAS-400H are equipped with NDIR and electrochemical sensors, providing simultaneous detection of CH₄ (0–100%), CO₂ (0–50%), H₂S (0–9999 ppm), O₂ (0–25%), and optional CO/H₂. This ensures that operators can evaluate gas purity and identify issues like high H₂S concentrations that may damage engines or desulfurization units.

Their fast response time (T90 < 15s) and high repeatability (±1%) make them ideal for daily process control, maintenance routines, or troubleshooting. The analyzer’s built-in sampling pump and battery-powered operation allow for easy use in outdoor digesters, confined engine rooms, or across decentralized facilities, without interrupting production.

Real-time data supports immediate adjustments to fermentation parameters such as feedstock composition or temperature, enhancing gas yield and reducing downtime. Additionally, accurate readings ensure compliance with clean energy certification programs and environmental audits.

In short, portable gas analyzers empower biogas facilities with data-driven control. They reduce operational risks, extend equipment life, and improve energy conversion efficiency—all critical for scaling sustainable energy production in a competitive market.

Can Portable Gas Analyzers Enhance Operational Safety In Sewage Treatment?

Toxic gases in sewage treatment plants pose silent, lethal threats to workers and equipment. Hydrogen sulfide (H₂S), methane (CH₄), and oxygen-deficient environments can cause respiratory failure, explosions, or corrosion without immediate warning. Fixed monitoring systems are often limited to specific zones, leaving many confined or remote spaces unprotected.

Portable gas analyzers close this safety gap with targeted, real-time detection. Devices like the IR-GAS-400H offer ppm-level resolution for H₂S and sub-2% accuracy across multiple gases including O₂ and CH₄. These analyzers utilize electrochemical and NDIR sensors to provide rapid feedback (<15s), enabling early identification of hazardous gas accumulations.

Their compact, handheld design allows technicians to safely check hazardous zones such as wet wells, digesters, sludge tanks, and sewer tunnels—areas typically inaccessible to fixed sensors. This flexibility is essential for pre-entry checks, maintenance operations, and emergency diagnostics.

With built-in sampling pumps and intuitive touch-screen interfaces, the analyzers simplify usage even in protective gear. The devices support real-time alarms and data logging, ensuring immediate response and traceable compliance with occupational safety regulations (e.g., OSHA, EU ATEX standards).

By empowering operators with portable, precise gas detection, these analyzers significantly reduce the risks of asphyxiation, poisoning, and fire. They ensure a safer working environment and improve preventive maintenance planning, ultimately contributing to the reliability and efficiency of sewage treatment operations.

Case: A City Municipal Sewage Treatment Plant

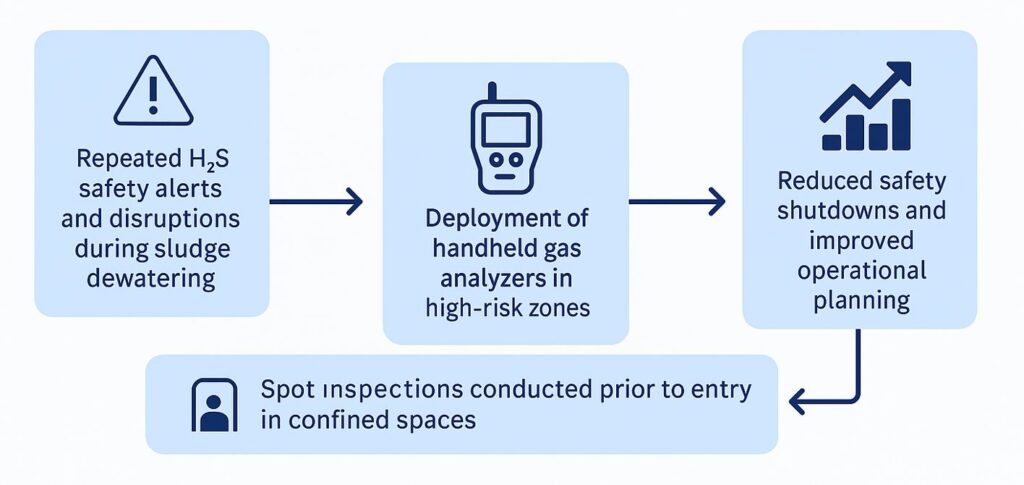

In 2024, a city’s Municipal Sewage Treatment Plant, one of the largest facilities in South China, faced repeated safety alerts due to unexpected spikes in hydrogen sulfide (H₂S) levels during sludge dewatering operations. These alerts frequently disrupted maintenance routines and raised concerns over potential worker exposure.

To address the issue, the facility deployed several IR-GAS-400H handheld gas analyzers for spot inspections in high-risk zones such as sludge storage pits, ventilation ducts, and sealed pumping rooms. Operators used the analyzers daily before entry to confined spaces, relying on the device’s quick-response electrochemical sensor to assess H₂S levels within seconds.

Within one month, the plant reported a 42% reduction in unplanned safety shutdowns. Moreover, real-time data logs enabled them to identify recurring gas buildup patterns tied to specific sludge volumes and ambient humidity, leading to adjustments in aeration schedules.

This proactive monitoring approach improved personnel safety, optimized operational planning, and ensured consistent compliance with local occupational safety regulations. The case demonstrates how portable gas analyzers are not just emergency tools but are integral to predictive safety management in complex wastewater systems.

Conclusion

IR-GAS-400H Handheld gas analyzers revolutionize industrial gas monitoring with their portability, accuracy, and multi-gas capability. From landfills to energy plants, they enhance safety, process control, and compliance—all within a compact device designed for the toughest environments.

If you have any questions, please contact us directly