When using a gas detector in daily operations, the detection range on the LCD label of the gas detector often displays values such as 0-100 LEL% or 0-2000 PPM, or similar units. Additionally, the LCD of the gas detector may show units like VOL% or PPM.

What do the unit symbols LEL%, VOL%, and PPM specifically represent, and can these units be converted between each other?

Gas Detection in LEL% (Lower Explosive Limit)

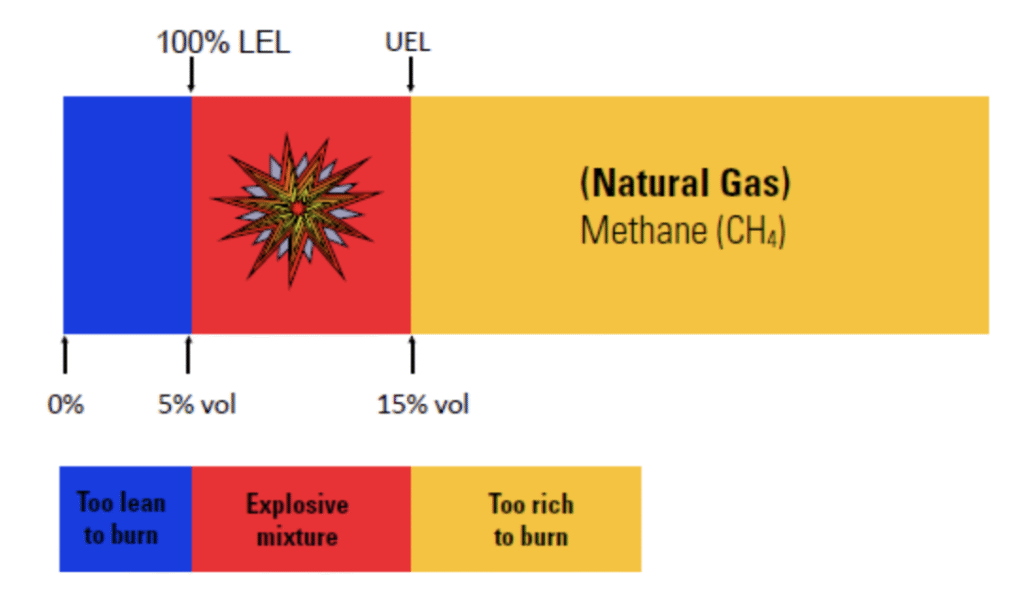

The concept of flammable gases refers to gases that can form a pre-mixed gas with air (or oxygen) within a certain concentration range and explode when exposed to an ignition source. The lowest volume percentage concentration of a flammable gas in air that can cause an explosion is known as the lower explosive limit concentration, abbreviated as LEL%, or simply “lower explosive limit.” The concentration of the gas volume at the lower explosive limit is expressed in VOL%, with the unit being a percentage. This means that the lower explosive limit is divided into 100 parts, with one unit being 1 LEL%.

Gas Detection in VOL% (gas volume percentage)

VOL is a physical unit used to describe gas volume, expressed as a percentage. It represents the percentage of a specific gas’s volume in air. For example, 5% VOL methane means that methane accounts for 5% of the volume in air.

The detection range of many gas detectors is expressed in VOL%. For example, a detection range of 0-100% VOL means that this gas detector can detect the concentration of a specific gas in air within the range of 0-100%. We can also set a specific percentage value of VOL as an alarm threshold. When the concentration of a gas reaches or exceeds this set value, the gas detector will sound an alarm.

Gas Detection in PPM (parts per million by volume)

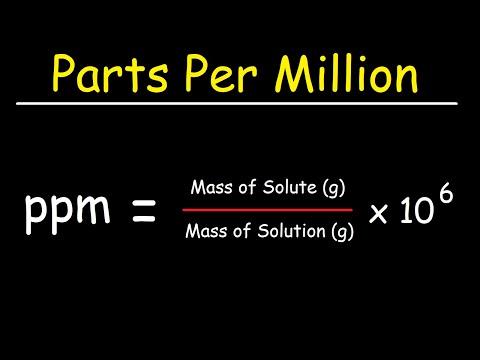

pic resource:The Organic Chemistry Tutor

For example, 10 PPM of carbon dioxide means that the air contains 10 parts per million of carbon dioxide. Since PPM is a dimensionless unit (a term specific to astronomy, it includes constants such as the mathematical constant π, the natural constant e, the radian (rad), the golden ratio (φ), and the relative molecular mass (Mr)), In contrast, dimensioned quantities have units such as length, area, and time. Dimensionless quantities are often expressed as the product or ratio of two dimensioned quantities, but the dimensions cancel each other out, resulting in a dimensionless quantity.

Gas detectors capable of detecting gas at the PPM level are used to detect gas micro-leaks in working environments. Gas micro-leaks are highly dangerous, as prolonged exposure to such leaks can lead to major accidents. Therefore, PPM-level gas detectors are essential for promptly detecting and eliminating micro-leaks.

Conversion between VOL%, LEL%, and ppm

First, let’s convert VOL and PPM. This conversion is relatively straightforward because %VOL represents the percentage of volume, while PPM represents parts per million by volume. Therefore, 1% VOL = 10,000 PPM.

Next, converting VOL to LEL requires determining the lower explosive limit (LEL) of the flammable gas. When the concentration of the flammable gas in the air reaches its LEL, the flammable gas environment is considered to have a 100% explosion hazard. For example, hydrogen’s LEL is 4% VOL, meaning that when its volume percentage in air reaches 4% VOL, it will explode upon contact with an open flame. Therefore, using 4% VOL as 100% hazard, it is referred to as 100% LEL, i.e., 4% VOL = 100% LEL. Thus, 1% VOL = 25% LEL. Third, converting PPM to LEL cannot be done directly. First, convert LEL to VOL, then convert VOL to PPM.

Here is a formula: PPM = %LEL × LEL (vol%) × 100. Using methane as an example, to determine the PPM of methane at 20% LEL, we apply the formula: 20 (%LEL) × 5 (%VOL) × 100 = 10,000 PPM. In addition to LEL%, VOL%, and PPM, gas detectors may use other units to indicate gas concentration, depending on the type of instrument and sensor, as well as the measurement range.

Additionally, different gas detectors may have different measurement ranges and accuracies. For example, some gas detectors may only measure low concentrations of gas, while others can measure high concentrations of gas.

Monitored Concentration of the ESEGAS Gas Analyzer

1. NDIR gas analyzer (non-dispersive infrared)

• Utilizes the absorption characteristics of gases at specific wavelengths in the infrared spectrum, enhancing sensitivity through a filter (GFC) and a long-path gas cell (L-Cell).

• Non-contact measurement, no sample gas consumption, and high stability.

Measurable Gases (Examples):

- Carbon Monoxide (CO): 0–10 ppm

- Carbon dioxide (CO₂): 0–500 ppm

- Methane (CH₄): 0–10 ppm

- Nitrous oxide (N₂O): Custom models available for measurement

Features:

- High accuracy, low drift, fast response

- Modular design, can be integrated into various industrial applications.

- Optional built-in temperature and pressure compensation for enhanced accuracy

Application areas:

2. TDLAS Gas Analyzer (Tunable Diode Laser)

Technical Principle:

- Utilizes Tunable Diode Laser Absorption Spectroscopy technology to modulate the laser wavelength to match the absorption lines of target gases.

- Features extremely high selectivity and sensitivity, making it ideal for trace gas detection.

Measurable Gases:

- Ammonia (NH₃), Hydrogen Chloride (HCl), Hydrogen Fluoride (HF)

- Acetylene (C₂H₂), methane (CH₄), and other trace gases

- Measurement Range:

- Covers ranges from ppb levels to percentage (%)

Features:

- Fast response time (<1 second)

- Unaffected by background gases, with strong resistance to cross-interference

- Supports fiber-optic remote measurement, suitable for hazardous environments

Application areas:

3. UV-DOAS Gas Sensor Module (Ultraviolet Differential Absorption Spectroscopy)

Technical Principle:

- Based on the principle of illuminating a gas channel with an ultraviolet light source and measuring the differential absorption curve of specific gas molecules in the ultraviolet wavelength range.

Measurable Gases:

- Sulfur dioxide (SO₂), nitrogen monoxide (NO), nitrogen dioxide (NO₂)

- Ammonia (NH₃), Hydrogen Sulfide (H₂S), Chlorine (Cl₂) etc.

- Measurement Range:

- Typically 0–2000 ppm (adjustable based on gas type)

Features:

- High resolution, strong interference resistance, particularly suitable for complex background gases

- Supports modular output, easy to integrate into system equipment

Application areas:

4. Portable FTIR Gas Analyzer (Fourier Transform Infrared)

Technical Principles:

- Utilizes full-spectrum scanning to simultaneously detect multiple gases and perform Fourier transform analysis.

Gases Measured:

- SO₂, NO, NO₂, CH₄, CO, CO₂, HCl, HF, NH₃, H₂O, and up to several dozen other gases

Measurement Range:

- Adjustable from ppm to % VOL, depending on the specific gas and configuration.

Features:

- Supports simultaneous analysis of 8–15 gases on a single unit.

- Portable design with built-in battery and touchscreen.

- Supports rapid on-site deployment, data logging, and remote analysis.

Application Areas:

5. Portable CEMS (Continuous Emission Monitoring System)

Technical Principles:

- Integrates multiple sensor technologies such as NDIR, UV differential, and TDLAS to accommodate various gases and measurement scenarios.

- Equipped with a sampling pre-treatment unit and data processing module to ensure high-reliability continuous measurement.

Measurable Gases and Typical Ranges:

- SO₂: 0–4000 ppm

- NO, NO₂: 0–3000 ppm

- CO: 0–5000 ppm

- CO₂: 0–20% VOL

- O₂: 0–25%

Features:

- Portable case design for easy mobility

- Suitable for field use or scenarios without fixed equipment

- Compatible with auxiliary parameter monitoring such as particulate matter, temperature, and humidity

Application Areas:

Temporary compliance testing in accordance with regulatory requirements

Environmental emission measurement in power plants, waste incineration plants, and glass and cement production lines

Conclusion

Therefore, when selecting a gas detector, it is necessary to choose the appropriate instrument and units based on the specific application scenario and requirements. Configuring the appropriate gas detector can provide timely and accurate gas concentration information, helping to prevent and control gas leaks and safety incidents.