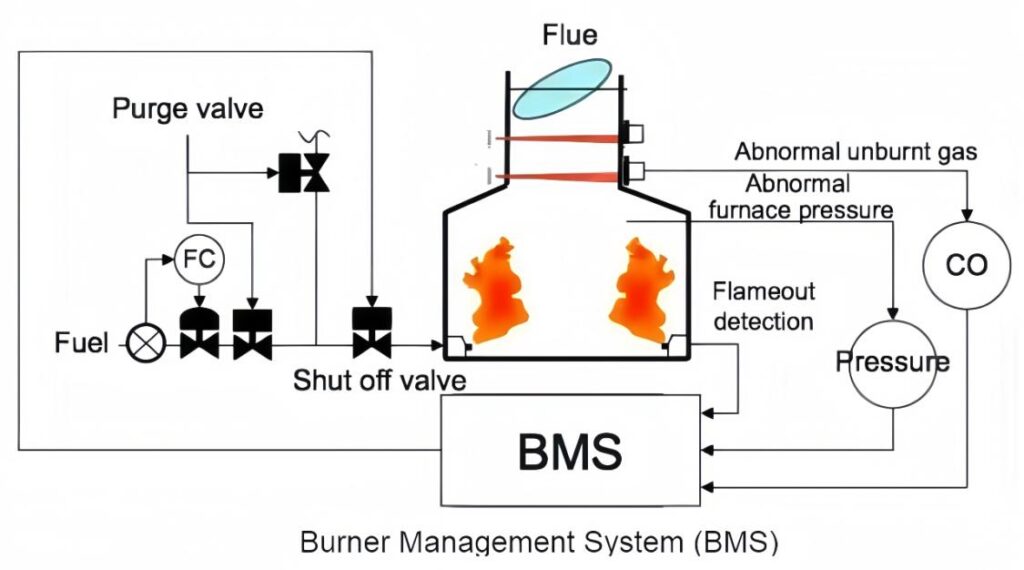

Industrial furnaces drive critical operations in steel mills, glass plants, cement kilns, and petrochemical units. Their success hinges on precise burner control—balancing fuel and air to achieve stable heat and peak efficiency. When combustion runs smoothly, you save energy, maintain uniform temperatures, and curb emissions. Conversely, poor control wastes fuel, triggers hot or cold spots, and spikes CO and NOₓ levels.

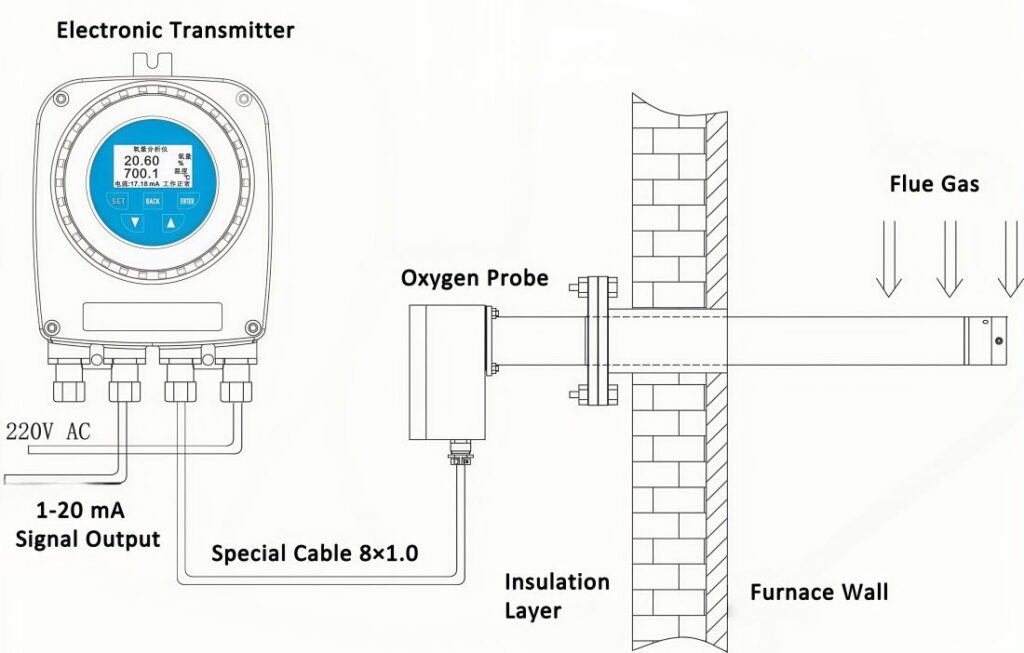

Fortunately, accurate oxygen measurement offers a clear path to better burner management. Here, the zirconia oxygen analyzer shines. This compact probe mounts directly in the flue gas stream and delivers real-time O₂ data. Armed with that insight, operators can tweak air–fuel ratios on the fly, ensuring each burner runs at its optimal point.

In the sections that follow, we’ll dive into how zirconia analyzers work, explore their fast response and wide measurement range, and reveal the tangible benefits they bring—from fuel savings and cleaner emissions to safer, more reliable furnace operation.

Why Is Burner Control Essential in Industrial Furnaces?

Burner control regulates how much fuel and air the furnace uses. The air–fuel mix affects flame stability, heat distribution, and energy use. For instance:

- Too much air cools the flame, sends heat up the stack, and squanders fuel.

- Too little air chokes the flame, builds carbon deposits, and risks dangerous carbon monoxide.

Achieving a stoichiometric balance—where fuel and oxygen burn completely—hinges on real-time, accurate O₂ data. Without it, operators often add excess air as a safety margin. Consequently, furnace efficiency drops and operating costs climb. Here’s where the zirconia oxygen analyzer makes a difference: it delivers precise, instant oxygen readings so you can fine-tune burner settings without guesswork or waste.

How Zirconia Oxygen Analyzers Work?

A zirconia oxygen probe relies on a solid electrolyte—usually yttria-stabilized zirconia—that conducts oxygen ions when heated. When flue gas oxygen pressure differs from reference air, ions migrate through the ceramic. That migration creates a voltage signal directly proportional to O₂ concentration. In other words, the sensor converts oxygen differences into an electrical reading. This clear, physics-based principle eliminates guesswork and delivers lab-grade accuracy inside your furnace’s harshest zones.

Moreover, zirconia analyzers thrive in extreme heat—up to 1,000 °C and beyond. They respond in mere seconds and measure oxygen from 0.1 % to 25 %. Such a wide range ensures you capture both lean and rich combustion conditions. As a result, you gain fast, precise feedback that feeds directly into your burner control loop. This allows operators or automated systems to tweak air–fuel ratios instantly, keeping flame stability and energy use optimized at all times.

What Are the Benefits of Zirconia oxygen analyzers for Burner Control?

Having covered how zirconia analyzers work, let’s dive into their top advantages. These benefits directly tackle common furnace challenges and help you run burners smarter and cleaner.

1. Real-Time Feedback for Closed-Loop Control

Zirconia probes feed live O₂ data into your control system. As fuel quality or load shifts, the loop instantly tweaks the air–fuel mix. This active feedback keeps combustion stable, reduces thermal swings, and cuts manual tuning.

2. Improved Fuel Efficiency and Temperature Uniformity

By trimming excess air, you raise flame temperature and boost energy transfer. That means more heat where you need it, fewer cold spots, and consistent product quality. Over time, tighter control can cut fuel use by several percent.

3. Lower Emissions and Easier Compliance

Optimized combustion slashes CO and NOₓ emissions. With zirconia sensors, you maintain clean burn conditions without extra scrubbers. As regulations tighten, having built-in O₂ monitoring simplifies reporting and avoids costly fines.

4. High Reliability in Harsh Environments

Zirconia probes withstand extreme heat, dust, and corrosive gases. Their solid-state design keeps moving parts to a minimum. Plus, models with auto-calibration and self-diagnostics free up technicians for higher-value tasks.

Together, these benefits make zirconia oxygen sensors an essential tool for plant engineers, EHS professionals, and control specialists aiming to optimize burner performance, cut costs, and meet environmental goals.

Where Are Zirconia oxygen analyzers Used?

Zirconia oxygen analyzers find vital roles across heavy-duty furnaces and kilns. Key applications include:

- Steel reheating & annealing furnaces

- Glass melting tanks

- Cement rotary kilns

- Petrochemical cracking furnaces

- Ceramic sintering ovens

Each of these processes demands tight control of flame temperature and air–fuel balance. By installing a zirconia oxygen probe, operators gain the precision needed to hit exact thermal setpoints and avoid costly over-air or under-air conditions.

In one steel mill, adding zirconia analyzers cut excess air by 15%. Consequently, the plant saved 5% on natural gas and saw a sharp drop in CO emissions. Meanwhile, a cement plant reported steadier clinker quality and less unplanned downtime after fine-tuning burner control with real-time O₂ data.

Moreover, these gains don’t just boost the bottom line. They also improve product consistency, extend refractory life, and simplify regulatory reporting. In today’s competitive market, that combination of cost savings, quality control, and compliance support makes zirconia gas analyzer technology a game-changer.

Conclusion

To sum up, zirconia oxygen analyzers equip furnace operators with real-time, high-temperature O₂ data. This insight lets you fine-tune burner control, cut fuel use, and slash emissions. By maintaining the perfect air–fuel balance, you run cleaner, leaner, and more efficient combustion cycles. Moreover, consistent flame stability improves product quality and protects refractory linings. In short, these analyzers transform furnace performance from guesswork to precision.

Next Steps: Take Action Today

- Ask for our product spec sheet to review zirconia oxygen probe specs.

- Request a technical consultation with our experts to tailor a solution for your operation.

- Schedule a pilot installation to see zirconia gas analyzer technology in action under your high-temperature conditions.

By integrating a zirconia oxygen probe, you’re not just adding a monitor—you’re upgrading your entire control strategy for long-term savings, compliance, and operational excellence.