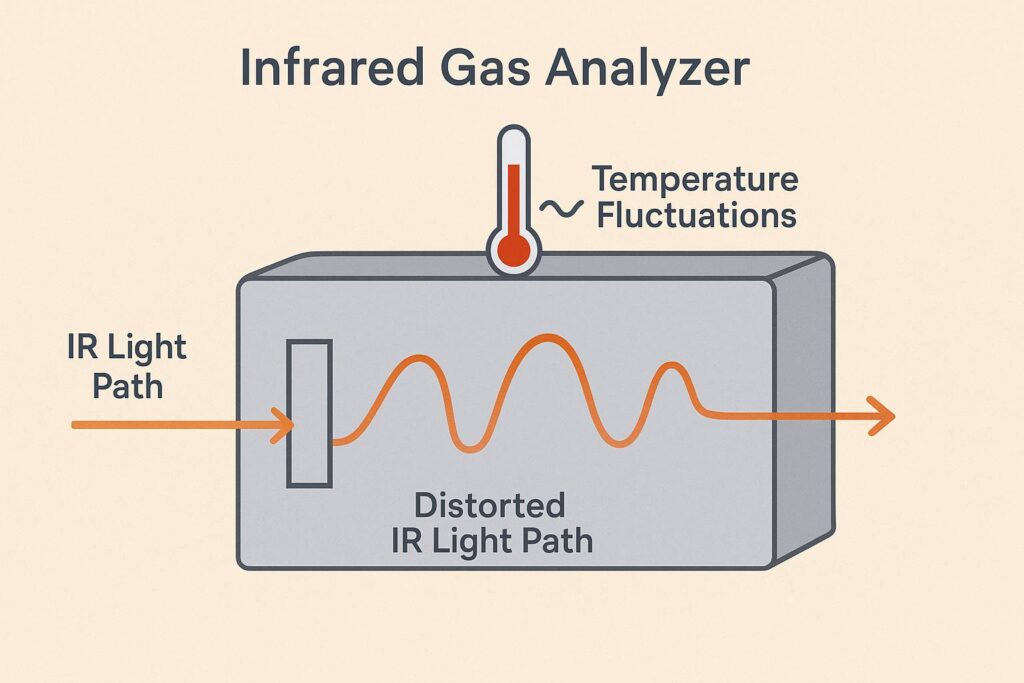

It often starts with a confusing morning at the plant. Overnight, temperatures dropped sharply, and by the first shift, the infrared gas analyzer began showing erratic readings—values drifting up and down with no clear cause. Operators checked the calibration, flow, and pressure—everything seemed fine. Yet, the readings refused to stabilize.

Such scenarios are common in industrial environments where ambient or stack temperatures swing rapidly—during morning start-ups, process surges, or cooling cycles. What many overlook is that temperature variation, though seemingly minor, can quietly distort gas measurements. It changes gas density, shifts the optical path, and alters the analyzer’s internal balance.

Temperature instability is not just a nuisance—it’s a root cause of unreliable data and poor process control. This article explores how temperature fluctuations skew infrared gas analyzer readings and offers practical strategies to prevent these hidden errors before they impact operations.

Why Temperature Fluctuations Matter for Infrared Gas Analyzers?

Temperature affects every component of an infrared gas analyzer—from the gas molecules in the sample to the optics and electronics inside the device. When temperature rises, gas density decreases, altering the number of molecules interacting with the infrared beam. Conversely, cooling increases density and absorption intensity. These shifts distort concentration readings even if the gas composition remains constant.

Mechanically, temperature swings cause expansion and contraction of optical components, slightly changing the path length or mirror alignment. Even micrometer-level movement can alter beam intensity or cause drift in baseline signals. At the same time, electronics and detectors experience thermal drift, where response sensitivity changes with internal heat variation.

It’s important to distinguish between stable high-temperature operation and rapid temperature fluctuations. A consistent thermal state can be compensated through calibration, but transitional swings disrupt equilibrium, leading to measurement instability. Therefore, preventing temperature-induced errors requires more than “keeping it warm.” It calls for integrated design—heated sampling lines, thermal insulation, real-time temperature monitoring, and compensation algorithms that stabilize both optics and electronics.

Where Do Temperature-Driven Problems Arise in Infrared Gas Analyzers?

Temperature issues often appear at multiple layers of an infrared gas analyzer system, each revealing unique symptoms and root causes.

1. Sampling Line & Front-End Design

Uninsulated or excessively long sampling lines allow rapid heat loss when ambient temperature dips. This leads to condensation, density change, and delayed gas transport.

- Symptoms: Slow response time, unstable baseline, delayed recovery after cooling.

- Root Indicator: Temperature gradient between sampling point and analyzer inlet.

- Principle: Thermal imbalance alters gas flow dynamics and density, skewing readings.

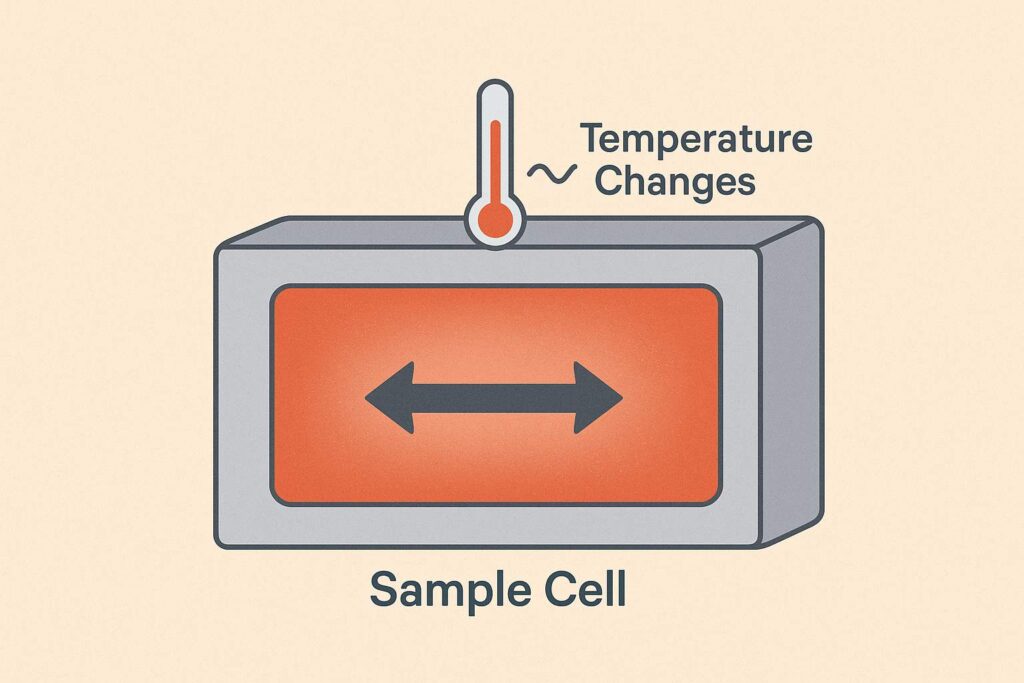

2. Optical Cell & Internal Components

Optical windows and mirrors expand or contract with temperature swings, disturbing alignment or beam intensity.

- Symptoms: Erratic output or sudden signal jumps after temperature change.

- Root Indicator: Correlation between internal cell temperature and output drift.

- Principle: Thermal expansion modifies optical path length and detector sensitivity.

3. Materials & Component Selection

Components with high thermal expansion (e.g., aluminum housings, low-grade plastics) worsen instability.

- Symptoms: Progressive reading shifts following temperature changes.

- Root Indicator: Material temperature coefficients mismatched with optics.

- Principle: Differential expansion distorts structural alignment and sensor calibration.

4. Environmental & Process Variations

Large stack or ambient swings, such as day-night cycles, introduce continuous drift.

- Symptoms: Output consistently tracks temperature trend.

- Root Indicator: Analyzer enclosure lacks thermal shielding or ventilation control.

- Principle: Fluctuating ambient conditions affect analyzer electronics and reference optics.

5. Gas Mixture & Absorption Changes

Temperature alters gas density and infrared absorption coefficients, leading to measurement bias.

- Symptoms: Readings drift with temperature even when gas concentration remains stable.

- Root Indicator: Cross-check with temperature-compensated reference gas.

- Principle: Changes in molecular energy levels and optical path modify true absorption behavior.

Together, these challenges reveal that temperature stability isn’t just about comfort—it’s about maintaining measurement integrity across every physical and electronic layer of the infrared gas analyzer system.

How Can You Prevent Temperature Fluctuations from Skewing Your Infrared Gas Analyzers?

Maintaining measurement accuracy for your infrared gas analyzer involves more than a one-off fix—it requires a lifecycle-based strategy. Let’s go through design, online control, and maintenance phases so you can build robust thermal protection from the start.

Design Stage

- Use insulated and actively heated sample lines, so the gas remains above dew point and avoids cooling during transport.

- Choose materials with low thermal expansion (e.g., stainless steel rather than simple plastic) to reduce distortion in the optical path.

- House the analyzer in a temperature-controlled enclosure. Temperature swings in the cabinet often mirror those in the sample line, impacting electronics and optics.

Online Control

- Monitor sample-line temperature and analyzer housing temperature in real time. Set alarms when line temperature nears ambient or drops rapidly.

- Implement compensation algorithms within your analyzer or control system to correct for known temperature effects—such as density changes or sensor drift.

- Ensure stable flow and temperature before measurement: allow gas to reach steady state after a heat change or process surge to avoid reading during transition.

Maintenance & Calibration

- Schedule inspections after thermal cycle events—e.g., start-up, shutdown, or seasonal change—to check for drift correlated with temperature swings.

- Track measurement drift versus temperature change in a log. Identifying patterns (for example, reading bias after night-cool) helps target root causes.

- Calibrate immediately when you find measurement error that correlates with temperature fluctuations. Don’t wait for drift to escalate.

What Should You Consider Before Implementing Temperature Control for Your Infrared Gas Analyzers?

(ESEGAS conditioning & heated line)

Rolling out temperature control for an infrared gas analyzer is never a one-size-fits-all decision. It’s about striking a balance—between investment, practicality, and long-term reliability.

1. Cost vs. Reliability

Heated lines and thermal enclosures undeniably add CAPEX and OPEX. Yet, the real question is: what’s the cost of unreliable data? Plants with tight emission limits or critical safety loops should treat temperature control as essential insurance, not an option. For less demanding applications, partial heating or selective insulation can be a cost-effective middle ground.

2. Retrofitting Legacy Systems

Many facilities still operate with unheated sampling lines or minimal insulation. When retrofitting, engineers face three choices:

- Extend thermal control to existing lines,

- Relocate the analyzer closer to the source, or

- Adjust the measurement protocol to account for temperature lag.

The right call depends on process risk, available power, and line accessibility. A simple rule: the more variable your ambient conditions, the stronger the case for thermal upgrades.

3. Operational Culture & Training

Even the best design fails if the team doesn’t understand it. Operators must recognize how temperature swings during startup, shutdown, or seasonal transitions can alter readings. Regular training helps staff identify early warning signs—such as drifting baselines or slow response times—before they trigger costly downtime.

4. Data Integrity & Trust

Repeated temperature-induced errors do more than skew data—they erode trust. When operators see frequent false alarms or unexplained spikes, they stop reacting. This human factor quietly defeats your instrumentation investment. A stable temperature system, on the other hand, reinforces operator confidence and keeps alerts meaningful.

5. Futureproofing the System

Infrared gas analyzers are becoming more thermally stable, but no sensor is immune to physics. The principle remains timeless: a well-designed, temperature-controlled sampling system outlasts any technology cycle. Future instruments may be smarter, but they’ll still rely on the same foundation—consistent thermal management and disciplined operation.

Conclusion

Temperature swings may seem harmless, but they quietly undermine the precision and reliability of infrared gas analyzers. Even modest fluctuations affect gas density, optical paths, and electronics—but the solution isn’t just “turn up the heat.” Instead, success depends on thoughtful design, active monitoring, and disciplined maintenance.

Ultimately, an infrared gas analyzer only becomes a trusted measurement asset when systems, people, and processes align to control thermal risk. If you’ve faced measurement issues from temperature swings—or simply want a complete review of your sampling system—reach out via our website. Our team is ready to help you build a resilient solution.

FAQ: How Do Temperature Fluctuations Affect an Infrared Gas Analyzer?

Q1: Why does my infrared gas analyzer reading change when the stack or ambient temperature fluctuates?

A: When temperature changes rapidly, an infrared gas analyzer can see shifts in gas density, optical alignment, and electronic sensitivity. Because IR measurements rely on light absorption through a specific path, any change in path length or gas density influences the reading—even if the gas concentration stays constant.

Q2: What’s the difference between a constant high temperature and a rapid temperature drop for an infrared gas analyzer?

A: A stable high temperature can often be compensated in calibration or design. But a rapid temperature drop introduces transitional instability—optics expand/contract, gas density shifts, electronics drift—and these transient effects cause measurement error far more than a steady elevated temperature.

Q3: How much temperature change is too much for an infrared gas analyzer?

A: While exact limits vary by instrument, many systems refer to ±10 °C ambient variation or more as problematic for full-scale accuracy. For example, the U.S. EPA notes that inadequate temperature stabilization in CEM analyzers can cause unacceptable drift.

ESEGAS NDIR gas analyzer working temperature is -20°C to 50°C. If your sampling line or analyzer housing sees large swings (>5-10 °C) during measurement, you should consider implementing thermal control or compensation strategies.

Q4: What symptoms indicate temperature-induced measurement problems in an infrared gas analyzer?

A: Typical signs include baseline drift during morning start-up, readings that track daily temperature swings, slow response after process surges, or sudden jumps when the analyzer housing warms or cools. If you recognize that reading errors correlate with ambient or stack temperature changes, this strongly points toward a temperature-related issue.

Q5: What steps should I take right away to address temperature-driven error in my infrared gas analyzer?

A: You should:

- Monitor your sample line and analyzer temperatures, log temperature vs reading.

- Verify that your sampling lines are insulated or heated and that the analyzer enclosure maintains a stable thermal condition.

- Adjust calibration schedules or apply compensation algorithms if readings shift consistently with temperature swings.

- Consult your analyzer documentation to ensure temperature effects are within specification and, if necessary, schedule an upgrade or retrofit.