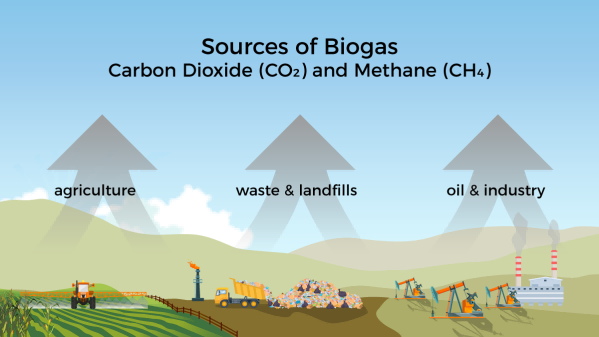

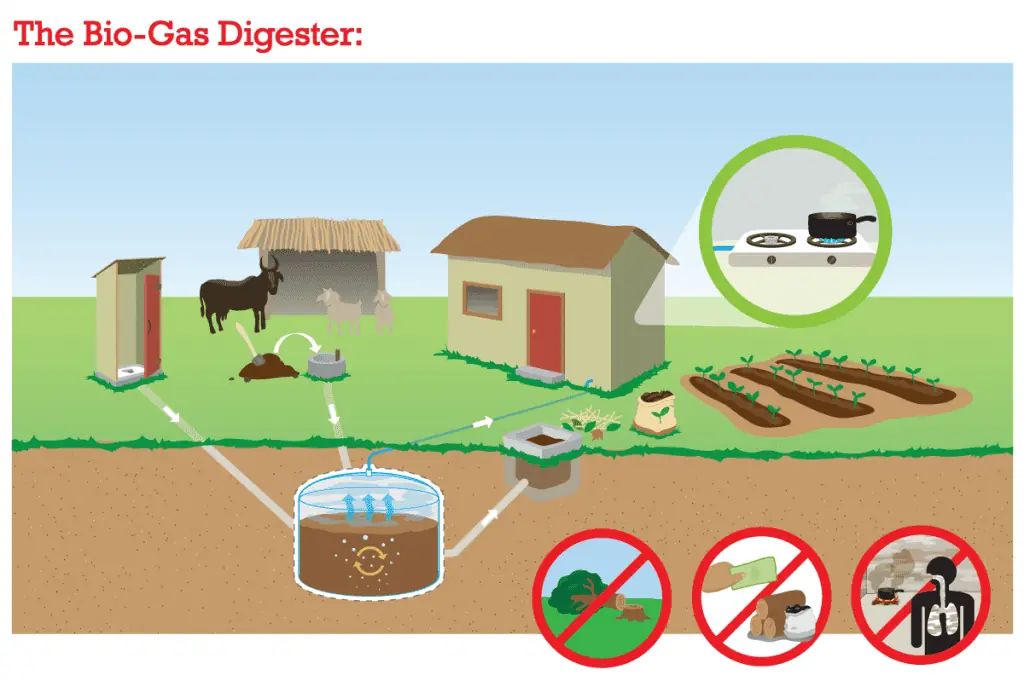

Biogas facilities are vital for renewable energy production, but they also present unique challenges, particularly in maintaining safety. Gas leaks, especially methane leaks, can have serious environmental and safety consequences. By using syngas analyzers, facility operators can effectively monitor and manage these risks, ensuring both environmental protection and operational efficiency. This article delves into the applications of syngas analyzers in detecting and preventing leaks in biogas facilities.

Syngas analyzers are essential tools for monitoring gas leaks in biogas facilities. By accurately analyzing gas compositions such as methane, hydrogen sulfide, and carbon dioxide, these devices provide real-time leak detection, preventing environmental contamination and ensuring the safe operation of biogas plants.

Gas leaks in biogas plants are a serious issue that can lead to severe environmental pollution, resource wastage, and even catastrophic safety events. Understanding how syngas analyzers work and how they help mitigate these risks is key for those involved in the management of biogas facilities. Let’s explore the critical roles these analyzers play in ensuring the proper functioning of biogas plants.

Application 1: How Do Syngas Analyzer Detect Methane Leaks in Biogas?

Methane, the primary component of biogas, is a potent greenhouse gas that contributes significantly to climate change when released into the atmosphere. Methane leaks are common in biogas facilities and can be dangerous, not only because of their environmental impact but also because of their flammability. How can syngas analyzers effectively detect and prevent these leaks?

- Syngas analyzers are equipped with highly sensitive sensors that can measure methane concentrations in biogas with great precision. These analyzers continuously monitor the levels of methane in the facility’s gas streams, offering real-time data on any fluctuations in gas concentration. When the methane level deviates beyond a predefined threshold, the analyzer triggers an immediate alert to operators. This early warning system allows the operators to act quickly, whether that means sealing a leak or adjusting the facility’s operations to minimize the risk.

- The key advantage of syngas analyzers is their ability to detect even minute changes in methane levels. Traditional methods of leak detection often rely on manual inspections or gas detectors with limited sensitivity. In contrast, syngas analyzers provide continuous, non-invasive monitoring, ensuring that even small leaks, which may go unnoticed with other methods, are quickly detected.

- Additionally, by integrating these analyzers with the facility’s control systems, operators can automate responses, such as activating ventilation systems or shutting down certain operations, to further minimize the risk of explosion or fire.

Application 2: How Do Syngas Analyzer Analyze the Risk of Other Harmful Gas Leaks?

While methane is the primary concern, biogas also contains other potentially hazardous gases, such as carbon dioxide (CO2) and hydrogen sulfide (H2S), which require careful monitoring. CO2 can displace oxygen and create asphyxiation risks, while H2S is toxic even at low concentrations. How do syngas analyzers ensure comprehensive leak detection, addressing not only methane but also these other harmful gases?

- Syngas analyzers are multi-gas detectors capable of identifying a wide range of gases present in biogas, including CO2 and H2S. The analyzers utilize advanced spectroscopic techniques, such as infrared (IR) absorption or electrochemical sensors, to identify and quantify these gases in real time.

- For instance, hydrogen sulfide is one of the most dangerous gases in biogas, and its detection is critical for worker safety. At high concentrations, H2S can cause respiratory distress, eye irritation, or even fatalities. Syngas analyzers equipped with specific sensors for hydrogen sulfide are able to measure even trace amounts of this toxic gas, providing alerts when H2S levels exceed safe limits.

- Similarly, carbon dioxide, while not as immediately dangerous as H2S, can pose significant risks in confined spaces or poorly ventilated areas. CO2 can accumulate in low-lying areas and displace oxygen, leading to asphyxiation hazards. Syngas analyzers can monitor CO2 levels in biogas and alert operators if concentrations become dangerous.

The ability to simultaneously monitor multiple gases within biogas—methane, CO2, H2S, and others—ensures that operators can take comprehensive action in case of a leak. By providing a clear and accurate picture of the gas composition, syngas analyzers enhance both the safety and operational efficiency of biogas facilities.

Application 3: What Role Do Syngas Analyzer Play in Equipment Maintenance?

Biogas facilities depend on complex equipment for gas production, storage, and processing. However, without regular maintenance, this equipment can degrade over time, leading to leaks or operational inefficiencies. Syngas analyzers play a crucial role in maintaining this equipment. How do they contribute to regular monitoring and proactive maintenance?

- Syngas analyzers are integral to the predictive maintenance strategy of biogas facilities. By continuously monitoring the gas composition, these analyzers provide early indications of potential equipment issues. For example, if the methane concentration begins to fluctuate in a manner that suggests a leak in a pipeline or storage tank, the analyzer can alert operators before the issue becomes critical. This allows technicians to address the problem before it escalates into a costly or hazardous failure.

- Moreover, the data provided by syngas analyzers can be used to track the performance of the facility’s equipment over time. Operators can observe trends in gas concentrations and identify potential inefficiencies, such as compressor malfunctions or gas purity issues, which might otherwise go unnoticed.

By integrating the analyzer’s data with the facility’s maintenance management system, operators can schedule maintenance and repairs based on real-time performance data, rather than relying on routine schedules or responding only after a problem arises. This proactive approach not only improves the reliability of the equipment but also reduces downtime and operating costs, as issues are identified and resolved before they lead to significant failures.

Application 4: How Do Syngas Analyzer Enhance Environmental Compliance?

Biogas facilities are subject to strict environmental regulations concerning gas emissions, especially methane, which is a major contributor to global warming. How do syngas analyzers help ensure that biogas plants remain compliant with environmental standards?

- Syngas analyzers are essential tools for ensuring environmental compliance in biogas facilities. Governments and environmental organizations have established stringent limits on methane emissions, and failure to adhere to these standards can result in hefty fines and reputational damage. Syngas analyzers provide real-time data on methane concentrations, allowing operators to monitor emissions and take corrective actions when necessary.

- By continuously tracking the gas composition, these analyzers ensure that methane leaks are detected quickly and that emissions are kept within legal limits. Additionally, the data generated by syngas analyzers can be stored and used as proof of compliance during audits or inspections. Some analyzers even offer remote monitoring capabilities, allowing regulatory agencies to access the data in real-time, further streamlining compliance.

- Furthermore, accurate emissions data helps biogas facilities optimize their operations. By understanding the exact concentrations of methane and other gases in their biogas streams, operators can improve the efficiency of their gas capture and storage systems, reducing both emissions and energy waste.

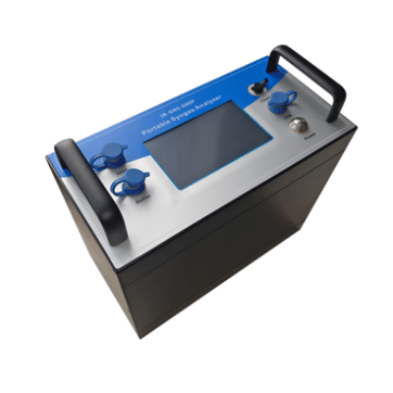

ESE Syngas Analyzer

- R-GAS-600 Continuous Industrial Syngas Analyzers and Gasification Analyzers

This model high-stability infrared detectors for simultaneously measuring CO, CO2, and CH4. H2 always reads correctly, independent of the background gas composition. An optional non-depleting paramagnetic sensor can be used to conduct O2 analysis. All sensors/detectors are temperature-controlled or temperature-compensated for maximum analytical stability. Both types of analyzers are available with analysis of:

- Carbon Monoxide (CO) via infrared detector

- Carbon Dioxide (CO2) via infrared detector

- Oxygen (O2) via electrochemical sensor or optional paramagnetic

- Methane (CH4) via infrared detector

- Hydrogen (H2) via thermal-conductivity detector

- the hydrogen reading is actively compensated for analytical interferences from CO / CO2 / CH4. This enables us to combine the durability of a thermal-conductivity detector while retaining the functional accuracy of a multi-gas instrument.

Applications

- Coal Chemical Process

- steel-making process as blast furnace

- converter, coking, direct iron, ore smelting reduction

- syngas production from Biomass and coal gas gasification processes

Specifications:

| INFRARED NDIR DETECTOR | |||||

| GAS | Lowest Range | Highest Range | LR resolution | HR resolution | Accuracy FS |

| CO | 0-5% | 0-100% | 0,001 % | 0,01 % | ≤ ±2% |

| CO2 | 0-5% | 0-100% | 0,001 % | 0,01 % | ≤ ±2% |

| CH4 | 0-5% | 0-100% | 0,001 % | 0,01 % | ≤ ±2% |

| Cn | 0-10% | 0,001 % | 0,01 % | ≤ ±2% | |

| THERMAL CONDUCTIVITY DETECTOR (TCD) | |||||

| H2 | 0-20% | 0-100% | 0,01% | 0,01% | ≤ ±3% |

| ELECTROCHEMICAL DETECTOR (ECD) | |||||

| O2 | 0-25% | 0,01 % | 0,01 % | ≤ ±3% | |

Conclusion

Syngas analyzers are indispensable tools for monitoring and managing gas leaks in biogas facilities. By detecting methane, hydrogen sulfide, carbon dioxide, and other gases, these analyzers ensure the safety of both personnel and the environment. Furthermore, their ability to track equipment performance and support maintenance activities helps improve the efficiency and longevity of the facility’s operations. In a world increasingly focused on sustainability and safety, syngas analyzers play a crucial role in ensuring the reliable and environmentally responsible operation of biogas facilities.

If you have any questions, please feel free to contact us!