Welcome to an enlightening guide about HF Gas Analyzers. Here, crucial knowledge about hydrogen fluoride and its detection will unfold. Read on for valuable insights into this critical, science-backed topic.

Understanding Hydrogen Fluoride!

Properties Of Hydrogen Fluoride

– Corrosive Nature

Hydrogen fluoride, abbreviated HF, is a corrosive compound. The use of HF gas analyzers aids in monitoring the levels of this harmful substance in various industries.

– Colorless Gas

HF stands out as a colorless gas. HF gas analyzers ensure safety by detecting this invisible, yet potentially harmful, substance in the atmosphere.

– Pungent Smell

HF emits a sharp, acrid odor. HF gas analyzers can detect its presence, even before the human nose can sense the pungent smell.

– High Toxicity

HF possesses a high toxicity level. Proper use of HF gas analyzers becomes essential to avert harmful exposure.

– Reactive

HF reacts easily with many substances. With HF gas analyzers, risks of unwanted chemical reactions get reduced significantly.

– Soluble in Water

HF has high water solubility. HF gas analyzers prove vital in monitoring any accidental spillage into water bodies.

– Strong Acid

Being a strong acid, HF poses serious threats. In light of this, HF gas analyzers act as a critical line of defense in industries.

– Non-flammable

Despite being non-flammable, HF still poses significant threats. Hence, the use of HF gas analyzers is crucial to ensure safety.

– Electro-negative

HF’s high electronegativity makes it reactive. HF gas analyzers are essential tools to detect this reactive substance, ensuring safety.

– Volatile

HF’s volatility makes it easily dispersed in air. Accurate HF gas analyzers detect these volatile emissions, protecting human health and the environment.

– Sharp, Burning Taste

HF’s sharp, burning taste makes it easy to detect. However, HF gas analyzers detect it safely, without the need for taste.

– Dissociates Partially

HF can partially dissociate into ions. HF gas analyzers can measure the concentration of these ions in different situations.

– Fumes in Air

HF can form fumes in the air. Reliable HF gas analyzers play a significant role in detecting these potentially harmful fumes.

– Thermal Stability

HF’s thermal stability makes it harder to break down. High-performance HF gas analyzers aid in the accurate detection of stable HF in various conditions.

– Heavy Vapor

HF’s heavy vapor sinks and accumulates at ground level. Therefore, HF gas analyzers become indispensable tools in safeguarding low-lying areas.

The Risk Of Exposure To Hydrogen Fluoride

– Skin Burns

HF gas analyzers help limit exposure, reducing skin burn risks. By detecting HF levels, workplaces can better protect employees and assets.

– Eye Damage

HF’s corrosive nature can harm eyes. Reliable HF analyzers can assist in mitigating such risks, ensuring optimal safety measures.

– Pulmonary Edema

Inhalation of HF gas may lead to fluid accumulation in the lungs. Precise HF analyzers aid in detecting unsafe levels, promoting better health practices.

– Inhalation Hazard

Breathing in HF gas can harm lungs. An effective HF analyzer alerts when gas concentrations reach hazardous levels, assisting in reducing inhalation risk.

– Systemic Toxicity

HF can affect the whole body. With HF gas analyzers, one can ensure timely detection and prompt action, thereby minimizing systemic toxicity.

– Bone Damage

HF can lead to calcium depletion in bones. Accurate HF analyzers play a crucial role in preventing such harmful outcomes.

– Metabolic Acidosis

Exposure to HF gas can disrupt body pH balance. HF gas analyzers provide a means of monitoring gas levels, helping prevent metabolic acidosis.

– Heart Arrhythmia

HF gas may cause irregular heartbeats. Employing reliable HF analyzers is critical for monitoring HF levels, thus, protecting heart health.

– Kidney Damage

Prolonged exposure to HF can affect kidneys. By using HF gas analyzers, the danger to kidneys can be minimized through prompt detection and action.

– Chronic Bronchitis

Inhalation of HF gas can lead to persistent lung issues. An efficient HF analyzer enables quick detection, thereby preventing long-term health problems like chronic bronchitis.

– Fatal at High Concentrations

High HF levels can be lethal. Hence, the importance of HF analyzers to detect dangerous concentrations, ensuring maximum safety.

– Airway Obstruction

HF gas inhalation may block airways. Advanced HF analyzers aid in quick detection, enabling immediate response to such health risks.

– Nervous System Effects

Exposure to HF can impact the nervous system. Timely detection through HF analyzers can help mitigate such potential effects.

– Chemical Pneumonitis

Breathing HF gas may cause lung inflammation. HF gas analyzers play a crucial role in detecting and preventing such risks, securing a safe work environment.

Types Of HF Gas Analyzers!

– Electrochemical

These analyze gas by producing an electrical signal. The stronger the gas presence, the higher the signal.

– Infrared (IR)

Using IR light absorption properties, these devices detect specific gases like HF.

– Photoionization (PID)

By using high-energy photons, PIDs ionize gas molecules. The resulting current gives the gas concentration.

– Semiconductor

These devices use gas-sensitive resistors. The resistance changes in the presence of HF gas.

– Conductivity

Here, the gas concentration is related to the conductivity of a sensor element.

– Spectroscopic

These devices analyze the spectral lines emitted by gas molecules. The HF concentration can be found through analysis.

– Tunable Diode Laser (TDL)

Utilizing laser light absorption, TDL analyzers can detect HF gas even in harsh conditions.

– Ultrasonic

Using sound waves, these devices measure the speed of sound in the gas. The speed changes with the concentration of HF.

– Colorimetric

These change color in the presence of HF gas. The degree of color change correlates with the concentration of gas.

– Catalytic Combustion

They use catalysts to ignite the gas. The heat released is proportional to the gas concentration.

– Metal Oxide Semiconductor (MOS)

MOS devices utilize a sensor that changes resistance when exposed to HF.

|

Type | Measurement Range | Accuracy | Response Time | Cross-Sensitivity |

Cost |

| Electrochemical | 0-100 ppm | ±2% FSD | 30-90 seconds | High for other acid gases | Low |

| Infrared (IR) | 0-1000 ppm | ±1% FSD | <30 seconds | Low for non-infrared active gases | High |

| Photoionization (PID) | 0-5000 ppm | ±1.5% FSD | <15 seconds | Moderate for other VOCs | Medium |

| Semiconductor | 0-500 ppm | ±5% FSD | <60 seconds | High for humidity, temperature | Low |

| Conductivity | 0-200 ppm | ±3% FSD | 30-120 seconds | High for other conductive gases | Medium |

| Spectroscopic | 0-5000 ppm | ±0.5% FSD | <2 seconds | Low for non-absorbing gases | High |

| Tunable Diode Laser (TDL) | 0-10,000 ppm | ±0.1% FSD | <2 seconds | Low for non-absorbing gases | High |

| Ultrasonic | 0-100% vol | ±0.1% FSD | <10 seconds | Low for non-gaseous substances | Medium |

| Colorimetric | 0-200 ppm | ±10% FSD | Instantaneous | High for color changing gases | Low |

| Catalytic Combustion | 0-100% LEL | ±2% FSD | 30-60 seconds | Moderate for other combustible gases | Low |

| Metal Oxide Semiconductor (MOS) | 0-1000 ppm | ±2% FSD | <60 seconds | High for humidity, temperature | Low |

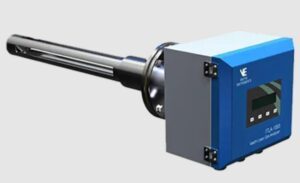

Principle of Operation of HF Gas Analyzers!

Detailed Explanation Of How HF Gas Analyzers Work

– Gas Sampling

The process begins with collecting the gas sample. The analyzer draws the sample into its chamber, ensuring accurate results.

– Signal Conversion

After gas sampling, conversion happens. The system changes the gas components into an electronic signal. Hence, the analyzer can process the information.

– Signal Amplification

In signal amplification, the electronic signal increases. It aids in the clear identification of gas components present in the sample.

– Gas Detection

In gas detection, the system identifies and measures the presence of hydrofluoric acid (HF) in the gas sample. Hence, it enables immediate response if required.

– Data Analysis

Next, the analyzer interprets the signal. The software evaluates the gas concentration in the sample, identifying the amount of HF.

– Result Display

After analysis, the system displays the result. The screen shows the HF concentration in the sample in parts per million (PPM).

– Alarm Triggering

If HF levels exceed safe limits, an alarm triggers. This feature enables immediate corrective actions, ensuring safety.

– Data Recording

The analyzer records data for future reference. Storage of data aids in trend analysis and regulatory compliance.

– Automatic Calibration

To maintain accuracy, the system performs automatic calibration. It compares the results against known values, adjusting as necessary.

– Self-Diagnostics

HF Gas Analyzers also carry out self-diagnostics. This feature ensures the system is functioning correctly, alerting to any potential issues.

– Power Management

Power management oversees the analyzer’s power usage. It ensures the system operates efficiently, saving energy.

– Communication Protocol

Lastly, the communication protocol allows for data exchange. It connects the analyzer to other systems for shared access and remote control.

Types Of Detection Methods Used

– Adsorption Spectroscopy

Adsorption spectroscopy measures how a gas adheres to a surface. This method is sensitive and precise, allowing for effective HF detection.

– Absorption Spectroscopy

Absorption spectroscopy observes how a gas absorbs light. The technique aids in the identification of various gas components, including HF.

– Emission Spectroscopy

This method examines the light a gas emits when energized. The distinct light patterns assist in identifying HF presence.

– Chemiluminescence

Chemiluminescence observes the light produced from a chemical reaction. If the gas sample contains HF, a unique light emission occurs.

– Ion Mobility Spectrometry

This technique separates ions based on their mobility. The speed at which the HF ions move helps in their detection.

– Optical Fiber Sensing

Optical fiber sensing uses light to detect gases. The changes in light transmission help identify HF in the sample.

– Raman Scattering

Raman scattering observes how light interacts with the gas molecules. This method accurately identifies the presence of HF.

– Differential Optical Absorption Spectroscopy

This approach measures the absorption of light at different wavelengths. The amount of absorbed light also aids in detecting HF.

– Photoacoustic Spectroscopy

This technique looks at the sound waves produced when a gas absorbs light. The unique sound patterns assist in detecting HF.

– Quantum Cascade Laser Spectroscopy

This method uses lasers to measure gas composition. The interaction of lasers with gas molecules aids in the detection of HF.

Features and Specifications to Look for in an HF Gas Analyzer!

– High Accuracy

An HF Gas Analyzer should offer superior accuracy, ensuring precise readings for safety and compliance.

– Rapid Response

Quick response times prove vital. Swift detection allows for immediate action to prevent harm.

– Long Sensor Life

Durability matters. Sensors with an extended lifespan can provide consistent results over time.

– Wide Range

A broad detection range equates to versatility. The device can monitor various concentration levels.

– Temperature Compensation

Fluctuating temperatures can distort readings. Hence, an analyzer with this feature corrects such inconsistencies.

– Rugged Design

An Analyzer should endure tough environments. A robust build ensures longevity.

– Ease of Use

Simplicity is key. An easy-to-use interface enhances the user experience, expediting the detection process.

– Good Repeatability

Reliable results, time after time, validate the precision of the analyzer.

– Low Maintenance

Reduced upkeep equals more productivity. Less frequent repairs keep operations running smoothly.

– Interference Immunity

To avoid false readings, the analyzer should resist external disturbances.

– Alarm Functionality

A timely alert system can mitigate potential hazards by warning of high HF concentrations.

– Data Logging

Recording data assists in trend analysis. This helps in understanding changes in HF levels over time.

– Power Options

Flexibility in power sources, like battery or AC, adds to the analyzer’s utility.

– Portability

Compact and lightweight designs can simplify on-site or remote operations.

Proper Installation of HF Gas Analyzers!

– Location Selection

The installation site significantly affects the analyzer’s performance. Hence, choose wisely.

– Mounting Process

Proper mounting stabilizes the device. This ensures accurate readings by reducing motion-related disruptions.

– Power Connection

Correct power setup is crucial. Wrong voltage can impair the device’s function.

– Signal Wiring

Properly connected wires are key. Faulty wiring can lead to incorrect data transmission.

– Sampling Line Installation

Proper setup of the sampling line ensures accurate gas sample collection.

– Alarm Setup

Correct alarm configuration is critical. Without this, warnings of high HF levels may go unnoticed.

– Ingress Protection

Suitable shielding protects the device from harmful particles or water.

– Grounding

Proper grounding prevents electrical faults and protects the device from damage.

– Ventilation Considerations

Adequate ventilation helps in maintaining the device’s function and prolongs its lifespan.

– Initial Calibration

The device needs precise calibration before use. Only then can it provide accurate readings.

– Operational Test

Before putting the analyzer into service, a successful operational test is necessary.

– Safety Compliance

Ensure the installation complies with all safety regulations. After all, safety should always be the priority.

Optimizing the Use of HF Gas Analyzers!

– Correct Calibration

Always start by calibrating your HF Gas Analyzer. Remember, calibration ensures precise gas measurement. It’s a crucial part of analyzer operation.

– Regular Maintenance

Frequent maintenance can prolong the analyzer’s lifespan. Change filters and clean the sensors regularly. Routine checks prevent unexpected downtime.

– Proper Installation

Install the analyzer in a safe location. Avoid areas with high dust or extreme temperatures. Good installation contributes to optimal performance.

– User Training

Understand how your analyzer works. Skilled handling of the device can enhance its function. Remember, knowledge is power.

– Data Analysis

Analyzing data effectively can reveal gas trends. Learn to spot patterns. These patterns can help predict potential issues.

– Response Time Minimization

Aim for fast response times. In high-risk areas, every second counts. Speedy response times can enhance safety measures.

– Alarm Settings

Configure the alarm settings correctly. Alarms alert you to dangerous gas levels. Timely alerts can prevent accidents.

– Power Management

Efficient power management can extend battery life. Schedule the device check-ups to ensure continuous operation. A powered analyzer ensures uninterrupted gas monitoring.

– Environmental Considerations

Consider the surroundings when placing the analyzer. Ensure the area is free from vibrations, which could affect readings. Environmental conditions play a key role in device performance.

– Interference Avoidance

Avoid electronic devices that may cause interference. Interference can lead to inaccurate readings. The right location is key for precise measurements.

– Sensor Protection

Protect sensors from physical damage. Damaged sensors may give false readings. Protection enhances device longevity.

– Effective Communication

Use clear, concise language when discussing readings. Good communication ensures everyone understands potential dangers. Stay safe through understanding.

– Safety Procedures

Follow all safety procedures during operation. Safety always comes first. Ensuring safety can prevent potential accidents.

Conclusion

Through this comprehensive exploration, knowledge about HF Gas Analyzers should be clearer. Essential aspects, from the nature of hydrogen fluoride to analyzer operation and maintenance, have been discussed. Next, put this knowledge into practice. Trust ESEGAS for all your gas analyzer needs. Keep safety and precision as top priorities in your operations.